Capsule type microbial fertilizer and preparation method thereof

A microbial fertilizer and microbial technology, applied in the field of microbial engineering and plant nutrition, can solve the problems of various factors, short shelf life of effective bacteria, unstable products, etc., so as to prolong the survival period, improve the lasting effect, and enhance the stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Sodium alginate concentration (W / V) 2.5%

[0035] Sodium alginate / sodium carboxymethyl cellulose (W / W) 5:1

[0036] Ratio of sodium alginate to bentonite (W / W) 5:1

[0037]Calcium chloride concentration (W / V) 5%

[0038] Mushroom slime / wall material (V / V) 1:1

[0039] Sodium alginate, sodium carboxymethyl cellulose, and bentonite were mixed according to the above proportions, and a calcium chloride solution was prepared; sterilized by damp heat at 121° C. for 20 minutes, and set aside. Mix the pre-cultivated beneficial microorganisms centrifuged at 10,000rpm with the wall material solution in proportion, then use a syringe to draw the mixed solution and drop it into the calcium chloride solution at a uniform speed, fix it for 30 minutes, and then use a non-toxic Rinse the capsules with bacterial water for 3 times to obtain capsule-type microbial fertilizers.

[0040] The particle diameters of the obtained wet and dry capsules are respectively 2.65-2.90mm and 1.00-1....

Embodiment 2

[0042] Sodium alginate concentration (W / V) 2.0%

[0043] Sodium alginate / sodium carboxymethyl cellulose (W / W) 10:1

[0044] Ratio of sodium alginate to bentonite (W / W) 10:1

[0045] Calcium chloride concentration (W / V) 5%

[0046] Mushroom slime / wall material (V / V) 3:1

[0047] The preparation method is the same as in Example 1.

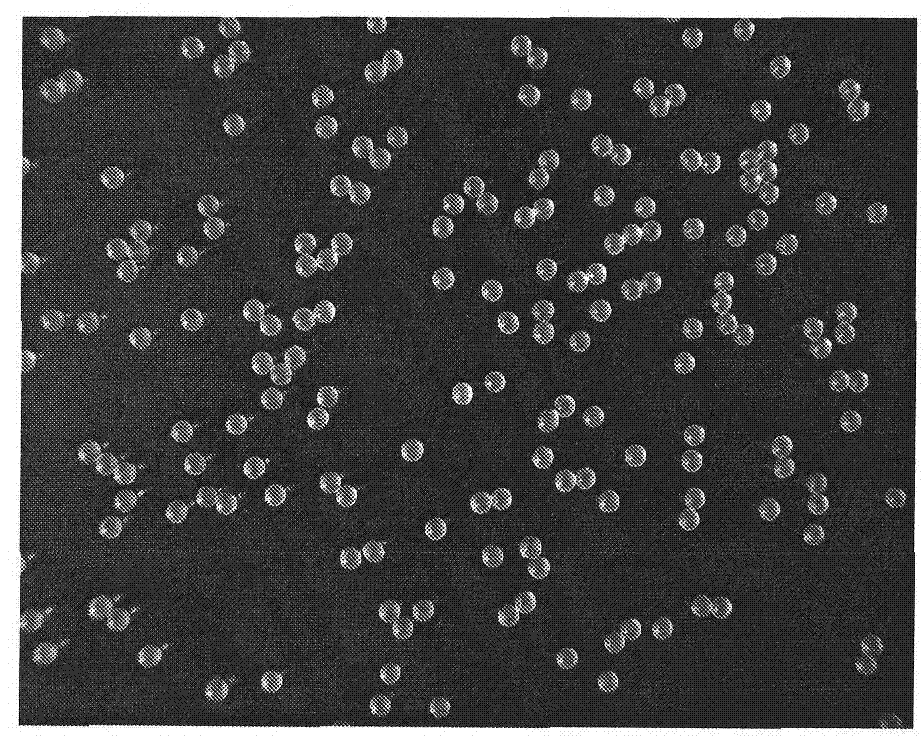

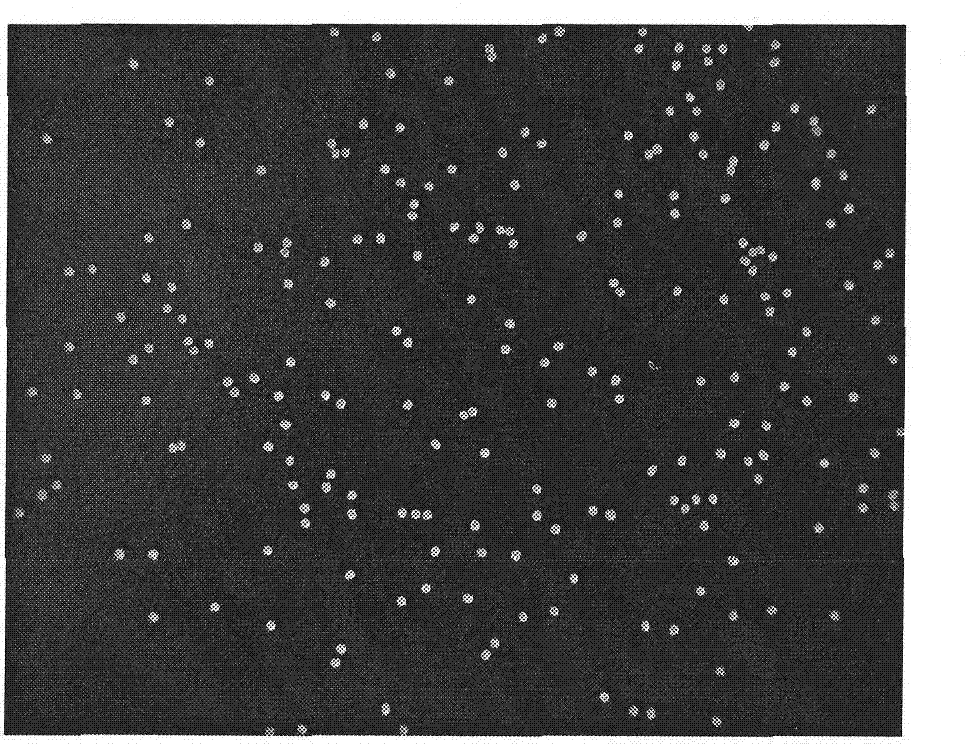

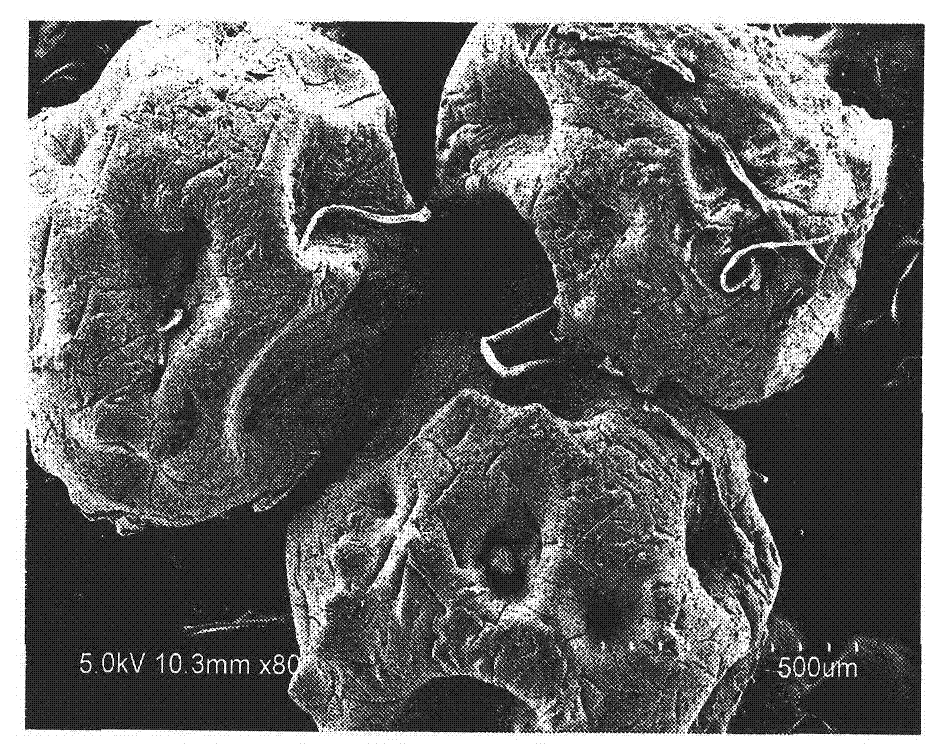

[0048] The properties of the obtained capsules are: the particle diameters of the wet and dry capsules are 2.48-2.70mm and 0.90-1.10mm respectively, the water content is 95%, the diameter diffusion coefficient of the dry capsule is 1.42, the mass diffusion coefficient is 2.0, and the embedding rate is 99.99% %, containing up to 10 live bacteria 14 CFU / g, the number of live bacteria that can be released is up to 10 9-10 CFU / g. Dry to constant weight at room temperature. After two months of storage, the effective bacteria content can reach 10 8-9 CFU / g, the obtained capsules are as attached figure 1 , 2 , 3, 4 shown.

Embodiment 3

[0050] Sodium alginate concentration (W / V) 1.5%

[0051] Sodium alginate / sodium carboxymethyl cellulose (W / W) 8:1

[0052] Ratio of sodium alginate to bentonite (W / W) 8:1

[0053] Calcium chloride concentration (W / V) 2%

[0054] Mushroom slime / wall material (V / V) 2:1

[0055] The preparation method is the same as in Example 1.

[0056] The particle diameters of the obtained wet and dry capsules are respectively 2.38-2.55mm and 0.85-1.00mm, the water content is 96%, the diameter diffusion coefficient of the dry capsule is 1.40, the mass diffusion coefficient is 1.9, and the embedding rate is 99.99%. Viable bacteria count up to 10 14 CFU / g, the number of live bacteria that can be released is up to 10 9-10 CFU / g. Dry to constant weight at room temperature. After two months of storage, the effective bacteria content can reach 10 8-9 CFU / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com