Hybrid ordered mesoporous silica gel chromatograph stationary-phase stuffing and preparation method thereof

A hybrid mesoporous and silica gel technology, applied in chemical/physical processes, ion exchange, ion exchange treatment devices, etc., to achieve the effect of reducing column pressure, good water resistance, and reducing column pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Synthesis of Aminopropyl Hybrid Ordered Mesoporous Silica Gel

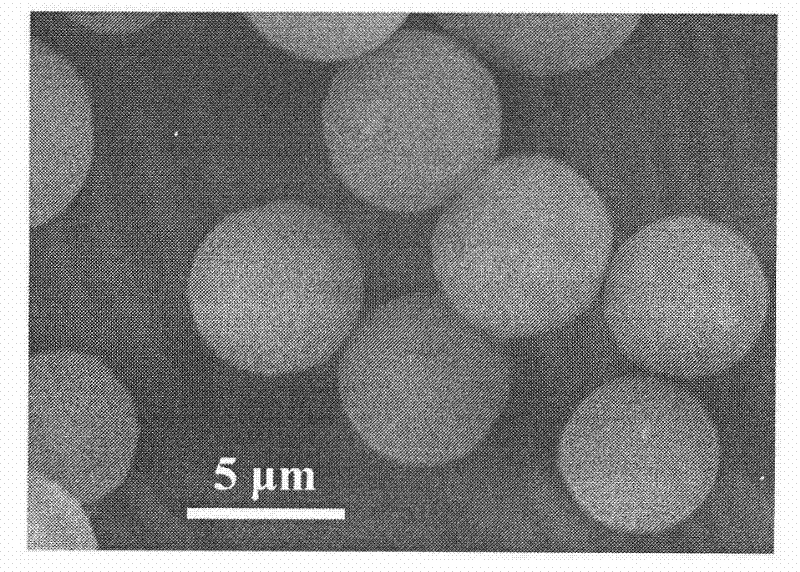

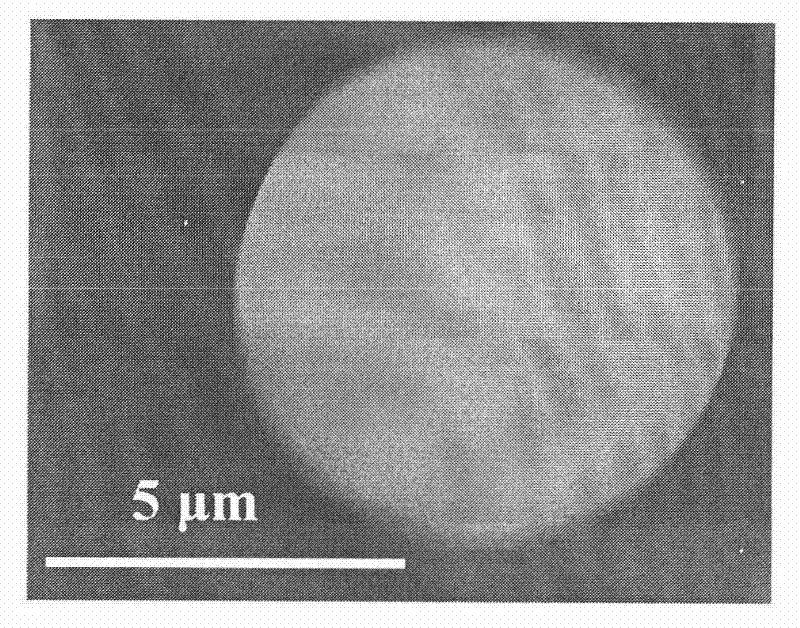

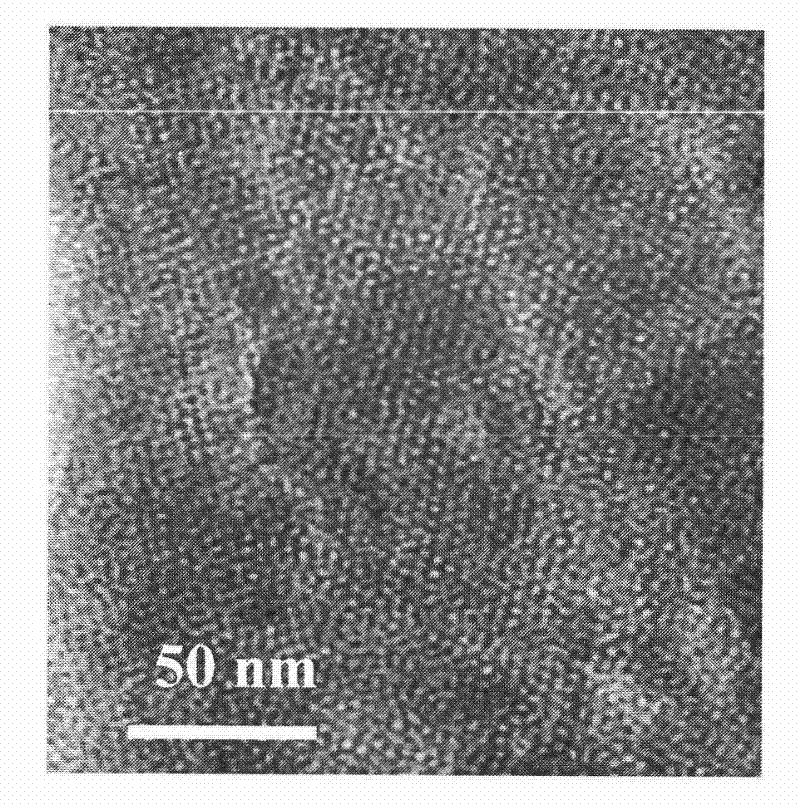

[0042] At room temperature, weigh 1.23g of N-trimethyloctadecylammonium chloride and place it in a 100ml round bottom flask, add deionized water 24.0ml, methanol 19.1ml and sodium hydroxide solution (0.66M, 14.0ml) successively, continuously Stir vigorously to make it evenly mixed to obtain a clear and transparent solution. Under vigorous stirring, 1.50ml of 1,2-bis(triethoxysilyl)ethane and 0.35ml of aminopropyltriethoxysilane were added rapidly, and the stirring was continued for 5 hours at room temperature, and then the reaction solution was transferred to poly Stand still at 90°C for 21 hours in a PTFE reaction kettle, filter, wash thoroughly with deionized water, and dry at 90°C under normal pressure for 10 hours to obtain aminopropyl hybrid silica gel, which has a spherical shape with uniform particle size, see figure 1 and figure 2 . Its transmission electron microscope picture is shown in imag...

Embodiment 2

[0044] Synthesis of Aminopropyl Hybrid Ordered Mesoporous Silica Gel

[0045] At about 25°C at room temperature, weigh 1.47g of N-trimethyloctadecylammonium chloride and place it in a 100ml round-bottomed flask, add 28.8ml of deionized water, 22.8ml of methanol and sodium hydroxide solution (0.66M, 17.0 ml) Stir vigorously continuously to make it evenly mixed to obtain a clear and transparent solution. Under vigorous stirring, 1,2-bis(triethoxysilyl)ethane (1.44ml) and 0.66ml of aminopropyltriethoxysilane were added rapidly, and stirring was continued for 4 hours at room temperature, and then the reaction solution was transferred Put it in a polytetrafluoro reactor at 120°C for 16 hours, filter, wash thoroughly with deionized water, and dry at 90°C under normal pressure for 10 hours to obtain aminopropyl hybrid silica gel, which has a spherical shape with uniform particle size.

Embodiment 3

[0047] Solvent extraction to remove templating agent

[0048] Weigh 0.5 g of the spherical aminopropyl hybrid ordered mesoporous silica gel crude product synthesized in Example 2 and suspend in 150 ml of acidic ethanol (200 ml of absolute ethanol contains 3 ml of 36% concentrated hydrochloric acid), stir and react at room temperature for 10 hours, filter , fully washed with absolute ethanol, and dried under normal pressure at 90°C; this operation was repeated once to obtain aminopropyl hybrid ordered mesoporous silica gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com