Powder forging and molding method for preparing porous amorphous alloy block material

A technology of amorphous alloy and amorphous powder, which is applied in the field of powder forging and pressing for the preparation of porous amorphous alloy bulk materials. Achieve good designability, uniform pore size distribution, and simple dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Preparation of a Zr with a pore size of less than 65 μm and a porosity of 30% to 40% 50 Cu 40 Al 10 Bulk Porous Amorphous Alloy Materials

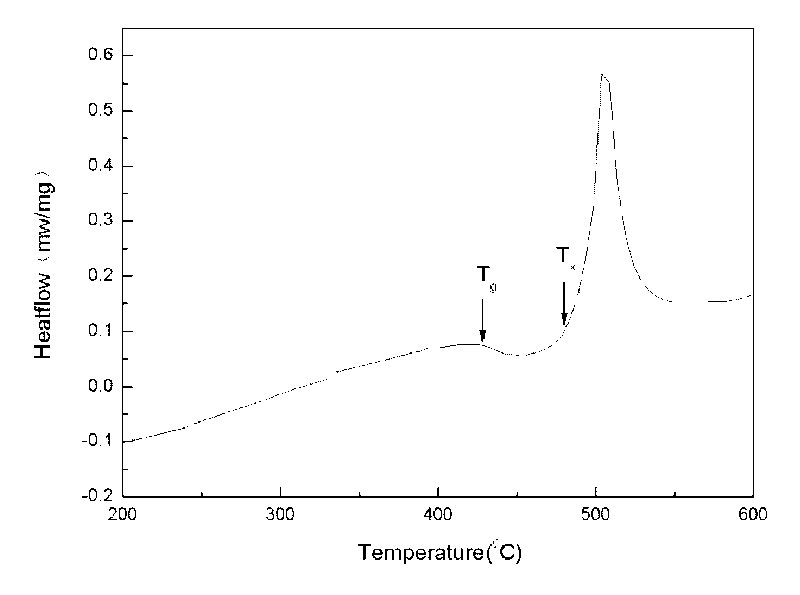

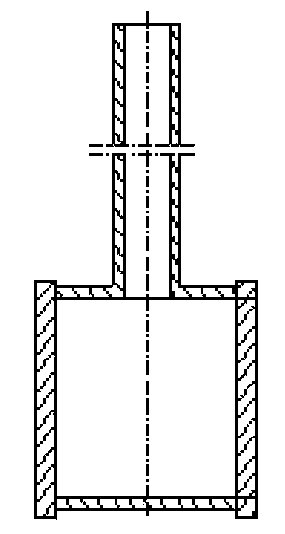

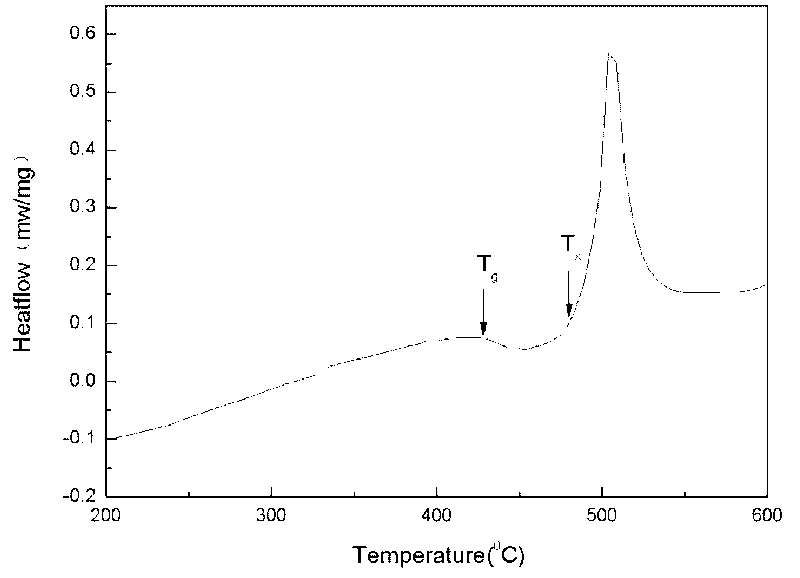

[0036] Argon atomized Zr 50 Cu 40 Al 10 Powder, Zr with a particle size of 74 μm to 38 μm after sieving 50 Cu 40 Al 10 Amorphous powder, Zr measured by DSC 50 Cu 40 Al 10 Tg=438°C and crystallization temperature Tx=497°C of amorphous powder (inert atmosphere, heating rate is 20k / min, see figure 1 ). Select NaCl powder with a particle size of less than 65 μm (the powder is classified by sieving or other methods) as a pore-forming agent, heat it in a drying oven at 100°C to 200°C for 5h to 10h, ventilate, dry and dehydrate. Zr with a particle size of 74 μm to 38 μm 50 Cu 40 Al 10 Amorphous powder and NaCl powder smaller than 65 μm, calculate the volume and mass according to the volume ratio of 7:3, weigh the powder according to the mass, and mix with a V-type mixer for 90 minutes. Put the uniformly mixed amo...

Embodiment 2

[0037] Implementation Example 2: Preparation of a Zr with a pore size of less than 38 μm and a porosity of 40% to 50% 50 Cu 40 Al 10 Bulk Porous Amorphous Alloy Materials

[0038] Argon atomized Zr 50 Cu 40 Al 10 Powder, after sieving to obtain Zr with a particle size of less than 38 μm 50 Cu 40 Al 10 Amorphous powder, Zr measured by DSC 50 Cu 40 Al 10 Tg=438° C. and crystallization temperature Tx=497° C. of the amorphous powder (inert atmosphere, heating rate 20 k / min). Select NaCl powder with a particle size of less than 38 μm (the powder is classified by sieving or other methods) as a pore-forming agent, heat in a drying oven at 100°C to 200°C for 5h to 10h, ventilate, dry and dehydrate. Calculate the weight according to the volume ratio of 6:4, weigh the powder, and mix in a V-type mixer for 90 minutes. Then prepare according to the method and step of example 1 and obtain porosity and be 40%~50% Zr 50 Cu 40 Al 10 Open cell porous material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com