Energy storage type solar cell

A technology for solar cells and energy storage, applied in the field of solar cells, can solve problems such as no successful precedent, and achieve high social and economic benefits, low cost, and no carbon dioxide emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

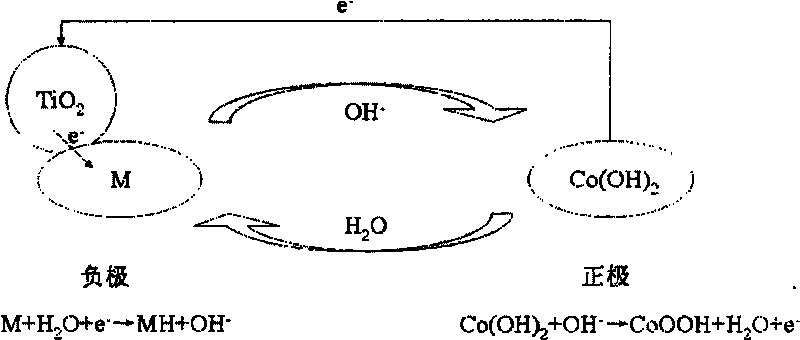

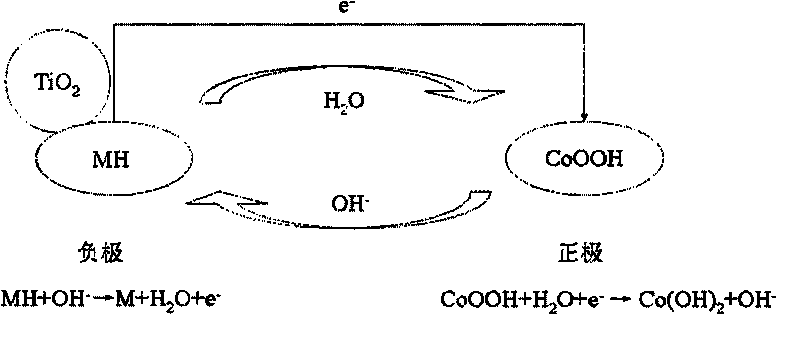

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Negative Electrode Fabrication

[0049] Get 0.1 g of anatase titanium dioxide powder (4.5 Al 0.5 (4.5 Al 0.5 、TiO 2 The mass ratio to PVA is 1:0.1:0.1. After drying, the nickel foam is coated with LaNi 4.5 Al 0.5 and TiO 2 The face of the conductive glass with indium tin oxide is coated with TiO 2 Facing to each other, put it on the conductive glass, leaving 0.5cm margin on each side of the glass, at 0.1kgcm -2 Compression molding under high pressure. Under the protection of inert gas, heat treatment at 500° C. for 10 minutes, and then cooling to prepare the negative electrode of the solar cell.

Embodiment 2

[0050] Example 2: Positive Electrode Fabrication

[0051] Take Co(OH) 2 (2 , The mass ratio of carbon black to PVA is 1:0.1:0.1. After drying, at 100kgcm -2 Compression molding under high pressure.

Embodiment 3

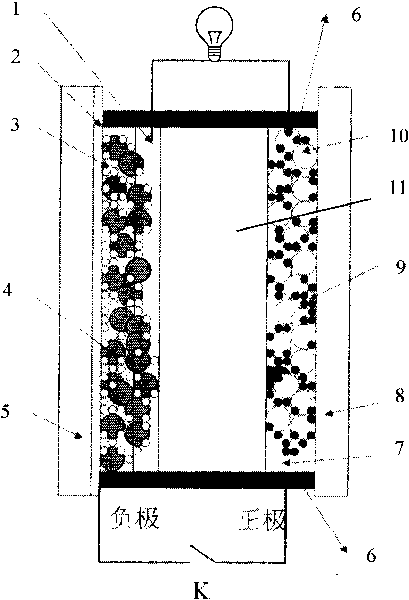

[0052] Example Three: Battery Assembly

[0053] Get 0.1 gram of anatase type titanium dioxide powder (2 The mass ratio to PVA is 1:0.2:0.2. After drying, the nickel foam is coated with TiNi and TiO 2 The face of the conductive glass with indium tin oxide is coated with TiO 2 Facing to each other, put it on the conductive glass, leaving 0.5cm margin on each side of the glass, at 0.1kgcm -2 Compression molding under high pressure. Under the protection of inert gas, heat treatment at 500° C. for 10 minutes, and then cooling to prepare the negative electrode of the solar cell.

[0054] TiO 2 The film side and the hydrogen storage metal side lead out to the terminal, and the positive electrode obtained in Example 2 is led out to the terminal. The hydrogen storage metal side of the negative electrode is opposite to the separator, and assembled with the positive electrode to form a sandwich structure. The material of the separator is a non-woven fabric made of polypropylene fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com