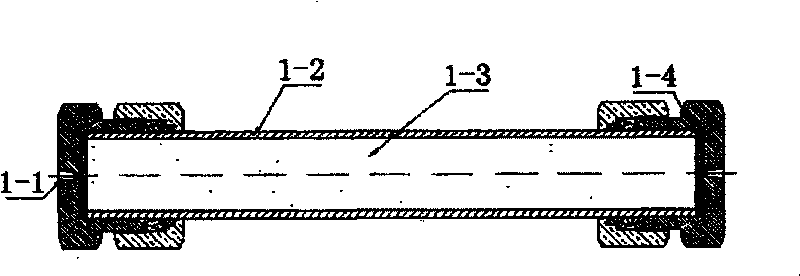

Mixed fillers of liquid-phase chromatographic column and chromatographic column

A liquid chromatographic column and mixed packing technology, applied in the field of liquid chromatographic column mixed packing and chromatographic column, can solve the problems of excessive retention, difficult separation, weak retention of hydrophilic substances, etc., and achieves good reproducibility and method. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

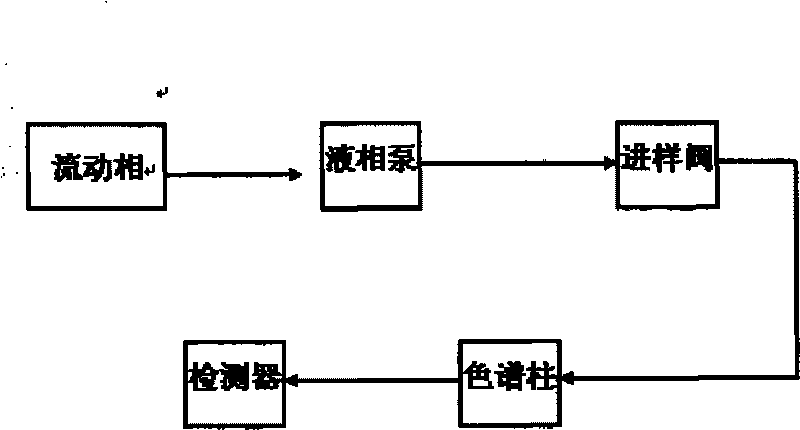

Method used

Image

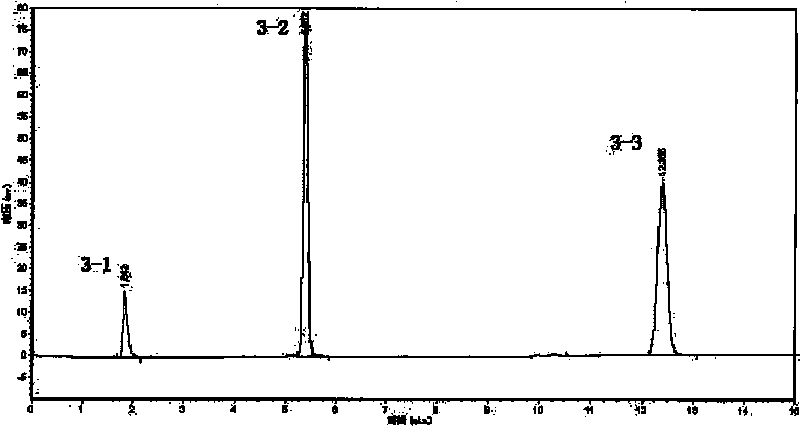

Examples

Embodiment 1

[0036] Silica gel preparation

[0037] Add 1240ml of purified water, 26g of concentrated nitric acid, 840g of silica sol (7.1%) and 37g of urea into a 6000ml beaker in sequence, and stir until the urea dissolves.

[0038] Add 100g of formaldehyde under rapid stirring, continue stirring for 15 seconds, room temperature 25°C.

[0039] After standing for 10-15min, a white precipitate precipitated out.

[0040] Stand for 5-8 hours, skim off the upper liquid, add pure water to stir, let stand for 30 minutes, skim off the upper liquid.

[0041] Wash 3 times with acetone and filter. Vacuum at 100°C and dry for 12 hours. Microscopic examination showed 4--5μm, spherical and uniform.

[0042] High temperature firing, 300°C, 3-4h; 500°C, 2-3h; 800°C, 2h; 1000°C, 3h.

[0043] After burning, 53 g of white solid was obtained; heated to 90° C. in 400 ml of 0.5 M HF aqueous solution for 4 hours; filtered, washed twice with 200 ml of pure water and three times with 200 ml of acetone; drie...

example 1

[0045] Add 50 g of silica gel prepared in Example 1, add 4 g of tetraethoxysilane, 1 g of triethylamine, and 200 ml of toluene; heat under electric stirring at 110 ° C for 16 hours; filter, wash with toluene 3 times, each dose of 100 ml, and Wash 3 times with methanol, each dose 100ml, then stir and wash with methanol and water mixture 3 times, each dose 150ml, wherein the volume ratio of methanol to water is 1:1, then wash 3 times with methanol, each dose 100ml; vacuum-dried at 100°C for 12 hours; 52g of white spherical solid powder was obtained. C % = 0.2.

example 2

[0047] The white solid 20g that prepares in the example 2, add EtOSi (CH 3 ) 2 CH 2 CH 2 CONH 2 10g, triethylamine 1g, toluene 100ml; heated at 110°C for 18 hours under electric stirring; filtered, washed 3 times with toluene, each dose 100ml, then washed 3 times with methanol, each dose 100ml, then methanol and water The mixed solution was stirred and washed 3 times, each dosage 150ml, wherein the volume ratio of methanol to water was 1:1, and then washed 3 times with methanol, each dosage 100ml; vacuum dried at 100°C for 10 hours; white spherical solid powder was obtained 22g. C% = 3.2, N% = 0.8. (0.5mmol / g)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com