Molecular imprinting material as well as preparation method and application thereof

A technology of molecular imprinting and template molecules, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problems of more interference in the detection process, lack of professional materials, etc., to reduce the use of organic solvents, The effect of small particle size and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 1mmol template molecule triazolam, 4mmol (0.3443g) a-methacrylic acid, 20mmol (3.9644g) ethylene glycol dimethacrylate to a 100mL three-necked flask successively, let it stand for 12h, and then add a mass concentration of 4 50 mL of dispersant PVA1750, 5 mL of porogen toluene and 0.04 g of AIBN were stirred and reacted for 24 hours at a constant temperature of 65° C. in a water bath at a stirring speed of 300 rpm.

[0032] Wash the obtained microparticles with methanol:acetic acid with a volume ratio of 7:3 in a Soxhlet extractor for 3 times, and the volume of the mixed solution is 10 times the mass of the microparticles, and detect with GC until no triazolam can be detected. until. Then wash with distilled water 4 times to pH 6.9.

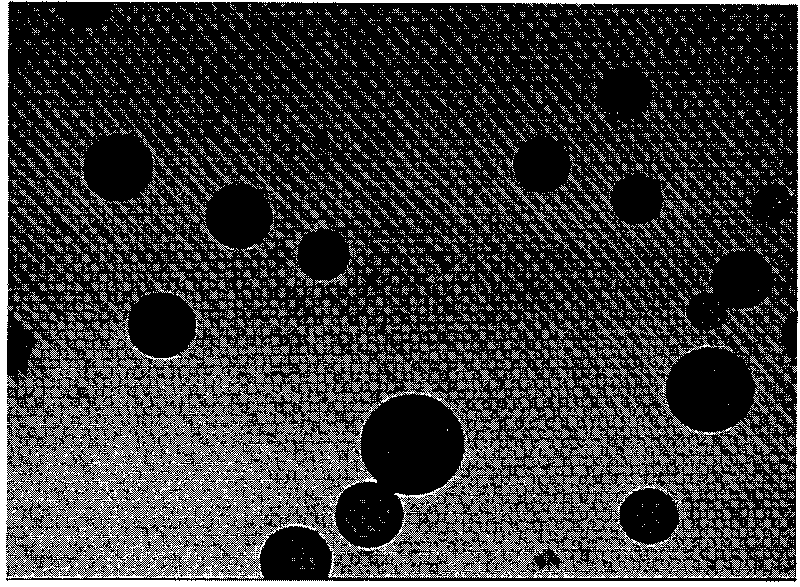

[0033] The obtained microparticles were vacuum-dried at 50°C, and the obtained microparticles (100-250 μm) were the desired triazolam molecularly imprinted materials (see attached figure 1 ).

[0034] Take 4 mL of urine and add 2 mg ...

Embodiment 2

[0036]Add 1mmol template molecule, 6mmol (0.426g) acrylamide, 10mmol (1.300g) 1,4-divinylbenzene to a 100mL three-necked flask in sequence, let stand for 12h, then add 50mL of 0.5% dispersant PVA1788, Add 15 mL of chloroform and 0.4 g of AIBN, and stir the reaction for 30 h at a constant temperature of 75 °C in a water bath at a stirring speed of 150 rpm.

[0037] Wash the obtained microparticles with methanol:acetic acid with a volume ratio of 7:3 in a Soxhlet extractor for 5 times. until. Then wash with distilled water 4 times to pH 6.8.

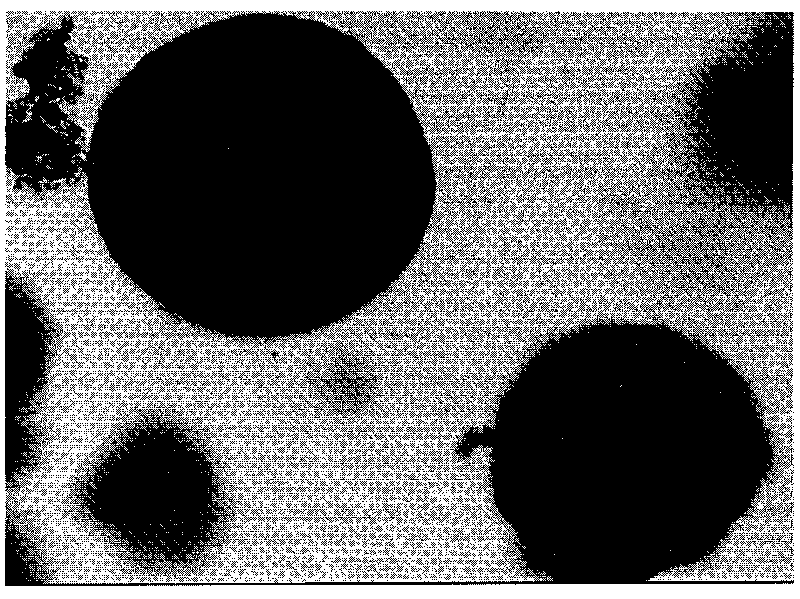

[0038] The obtained microparticles were vacuum-dried at 50°C, and the obtained microparticles (150-200 μm) were the required triazolam molecularly imprinted materials (see attached figure 2 ).

[0039] Take 4 mL of urine and add 2 mg of triazolam. Adjust the pH to 9 with sodium hydroxide solution, put in 0.1000g triazolam molecularly imprinted material (MIPs), absorb at 35°C for 4 hours, filter out the MIPs, add 2 mL of chloroform to ...

Embodiment 3

[0041] Add 1mmol template molecule, 8mmol (0.6886g) a-methacrylic acid, 15mmol (5.070g) trimethylolpropane trimethacrylate to a 100mL three-necked flask in sequence, let it stand for 12h, and then add 2% dispersant PVA1799 50mL, porogen chloroform 50mL and 0.04g AIBN were stirred and reacted at a constant temperature of 65°C in a water bath at a stirring speed of 350 rpm for 24h.

[0042] The obtained microparticles were refluxed and washed 4 times in a Soxhlet extractor with methanol:acetic acid with a volume ratio of 7:3. until. Then washed twice with distilled water to pH 6.5.

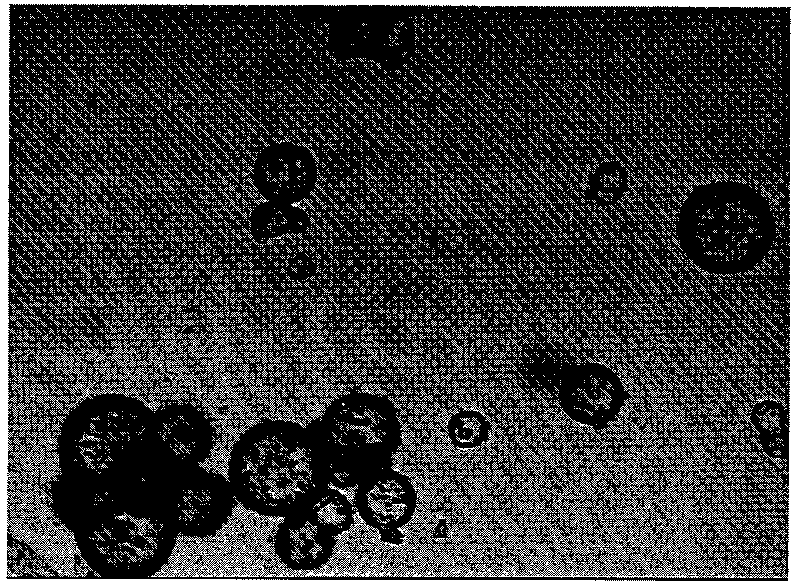

[0043] The obtained microparticles were vacuum-dried at 60°C, and the obtained microparticles (20-180 μm) were the desired triazolam molecularly imprinted materials (see attached image 3 ).

[0044] Take 4 mL of urine and add 2 mg of triazolam. Adjust the pH to 9 with sodium hydroxide solution, put in 0.1000g triazolam molecularly imprinted material (MIPs), absorb at 25°C for 4 hours, filter ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com