Method for preparing high-purity semi-insulating silicon carbide crystalloid

A silicon carbide and semi-insulating technology is applied in the field of preparing high-purity semi-insulating silicon carbide crystals, which can solve the problems of low production efficiency, low crystal point defect concentration, and incompatibility with the production needs of silicon carbide crystals, so as to improve the resistivity and reduce the The effect of the number of microtubules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

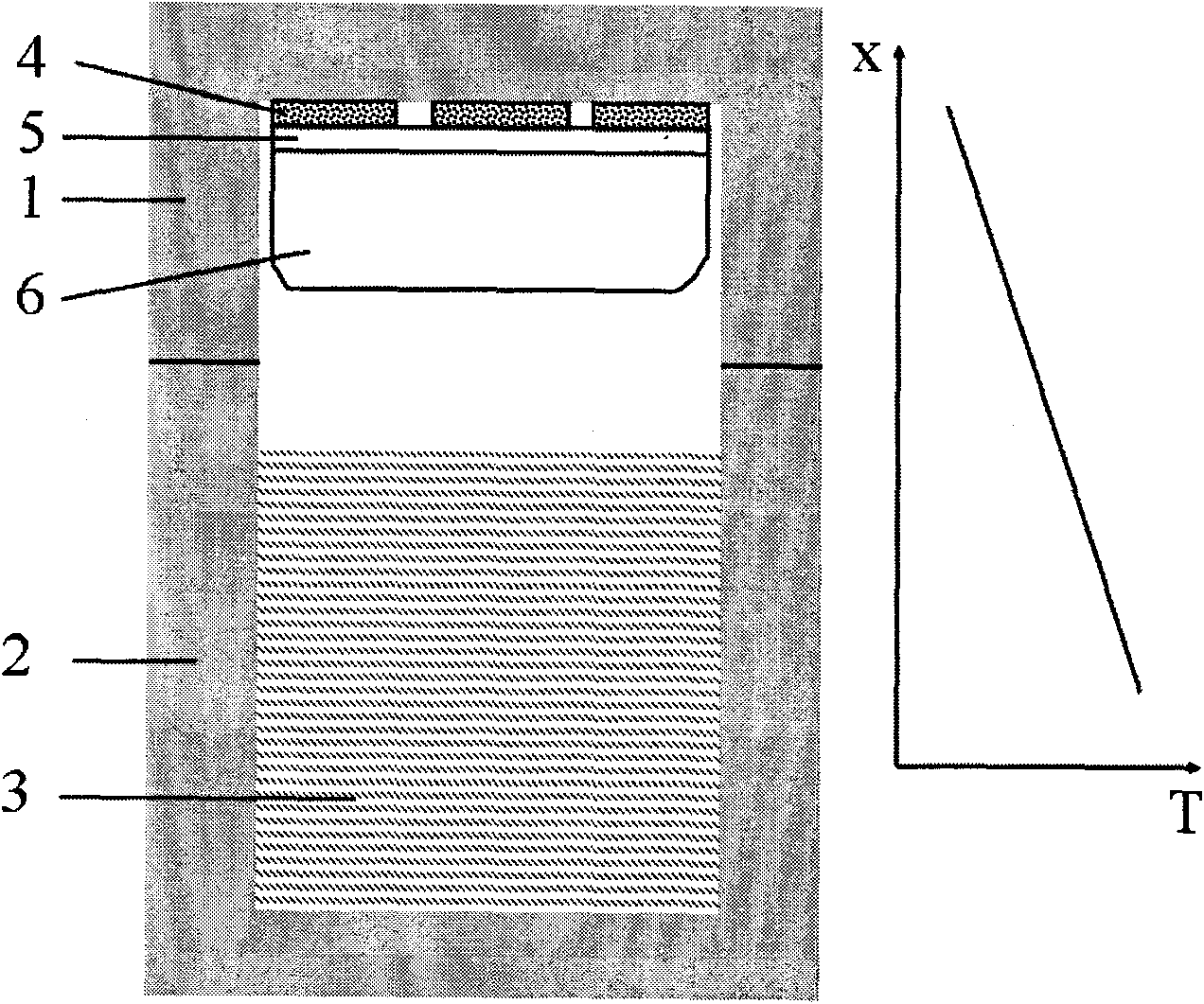

[0020] The present invention is a method for preparing non-doped high-purity semi-insulating silicon carbide crystals. The growth chamber is heated by an induction heating device. The structural diagram of the growth chamber is shown in the attachment figure 1 shown. The growth chamber mainly includes the following parts: graphite cover 1 , graphite crucible 2 , SiC raw material 3 , adhesive 4 , seed crystal 5 , and grown silicon carbide crystal 6 . The seed crystal 5 is bonded to the graphite cover 1 through the adhesive 4, the seed crystal 5 is placed in the upper area of the growth chamber, and the SiC raw material 3 is placed in the lower area of the growth chamber. figure 1 The right side is a schematic diagram of the temperature during the crystal growth process. The abscissa indicates the temperature, and the ordinate indicates the distance from the bottom of the growth chamber. During the growth process, the temperature in the growth chamber gradually decreases alo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com