Catalyst for hydrogenation of Fischer-Tropsch synthesis oil, preparation method as well as application thereof

A hydrogenation catalyst and Fischer-Tropsch synthetic oil technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve corrosion equipment, unfavorable synthetic oil processing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

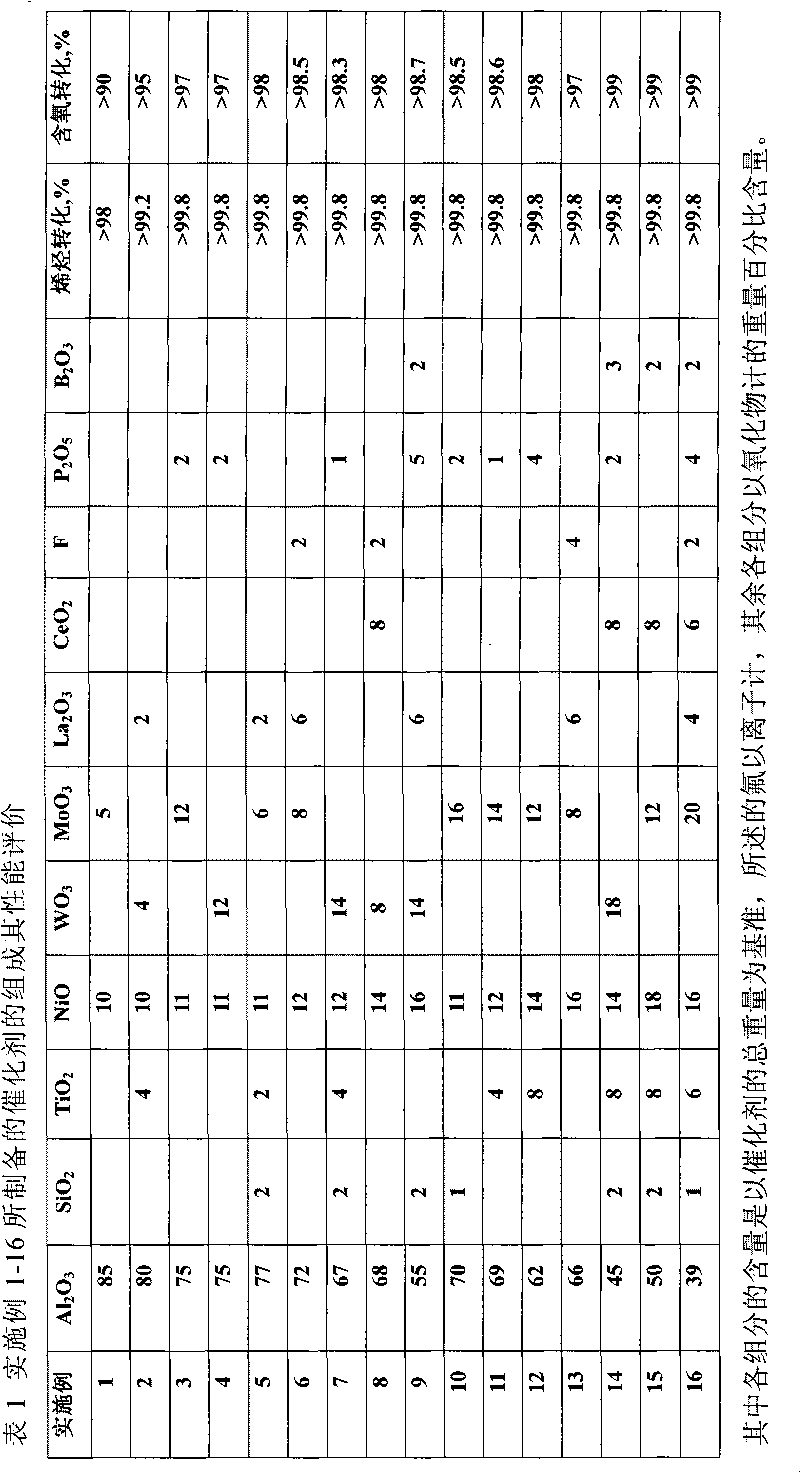

Examples

Embodiment 1

[0083] First, the γ-Al 2 o 3 The carrier was dried at 110°C and calcined at 500°C for 4 hours. Take by weighing 85g alumina carrier, then according to equal volume impregnation method, ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O, 6.10g) is prepared into a mixed aqueous solution of a certain concentration, and the Al 2 o 3 The carrier was added to the above solution, immersed for 12 hours, dried at 110°C for 12 hours, and roasted at 480°C for 4 hours; according to the equal volume impregnation method, the above intermediate product was added to nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O, 38.90g) impregnated for 12 hours, dried at 110°C for 12 hours, and calcined at 500°C for 3 hours to obtain Ni / Mo / Al 2 o 3 catalyst. Its weight percent composition ratio is: NiO: MoO 3 :Al 2 o 3 =10:5:85.

[0084] Weigh 20g Ni / Mo / Al 2 o 3 The catalyst (20 mesh to 40 mesh) is placed in a continuous flow fixed bed reactor. First, it was reduced in a hydrogen atmosphere at 420°C...

Embodiment 2

[0086] First, the powdered Al 2 o 3 Al 2 o 3 Powder; weigh the above Al 2 o 3 100g of powder and 6.13g of metatitanic acid powder, add 3g of sage greens powder, mix thoroughly, add 50ml of 5wt% dilute nitric acid solution, knead for one hour, extrude, and bake at 450-580°C for 3-6 hours, Available TiO 2 -Al 2 o 3 Composite carrier;

[0087] Take by weighing 84g titania-alumina carrier, then according to equal volume impregnation method, ammonium metatungstate ((NH 4 ) 2 W 4 o 13 ·8H 2 O, 4.85g), prepared into a mixed aqueous solution of a certain concentration, the TiO 2 -Al 2 o 3 The composite carrier was added to the above solution, immersed for 12 hours, dried at 110°C for 12 hours, and roasted at 480°C for 4 hours; according to the equal volume impregnation method, the above intermediate product was added to nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O, 38.90g), lanthanum nitrate (La(NO 3 ) 3 .6H 2 O, 5.31) in an aqueous solution, soaked for 12 hours, dried at ...

Embodiment 3

[0090] First, the γ-Al 2 o 3 The carrier is dried at 110°C, calcined at 500°C for 4 hours, at 500°C, WHSV=0.5h -1 Under certain conditions, steam treatment for 2 hours to obtain the desired alumina carrier.

[0091] Take by weighing 75g alumina carrier, then according to equal volume impregnation method, ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O, 14.7g) is prepared into a mixed aqueous solution of a certain concentration, and the Al 2 o 3 The carrier was added to the above solution, immersed for 12 hours, dried at 110°C for 12 hours, and roasted at 480°C for 4 hours; according to the equal volume impregnation method, the above intermediate product was added to nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O, 42.80g), phosphoric acid (H 3 PO 4 , 2.76g) in an aqueous solution, soaked for 12 hours, dried at 110°C for 12 hours, and fired at 500°C for 3 hours to obtain Ni / Mo / P / Al 2 o 3 catalyst. Its weight percent composition ratio is: NiO: MoO 3 :P 2 o 5 :Al 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conversion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com