Method for preparing laevoglucose ketone and special reaction equipment thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The method for preparing L-glucosone provided by the present invention, the specific preparation process is as follows:

[0014] Crush the cellulose or biomass raw material to less than 1mm, send the material into the pyrolysis reactor 4 through the feeder 2, control the pyrolysis reaction temperature to 400-500°C, and the heating rate to 10 3 -10 5 ℃ / s, the residence time of the pyrolysis gas in the reactor 4 is not more than 1s; then the pyrolysis gas is quickly introduced into the fixed-bed catalytic reactor 7 equipped with a chromium chloride catalyst, and the reaction temperature is controlled at 250-400°C, and the mass air The speed is 10-1000h -1 ; Finally, the pyrolysis gas is rapidly condensed in the spray condenser 8 by means of spray condensation to obtain a liquid product, which is discharged from the discharge port.

[0015] The following determination methods are conventional methods unless otherwise specified.

Embodiment 1

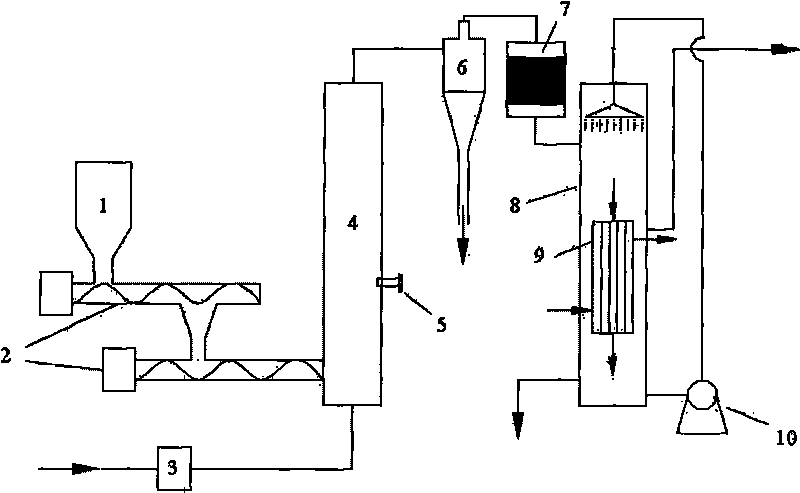

[0017] Using microcrystalline cellulose as raw material, it is prepared in the fluidized bed biomass fast pyrolysis equipment with a processing capacity of 10kg / h shown in Fig. 1 . In this equipment, the inner diameter of the pyrolysis reactor is 70mm, and the bed height is 2m; the inner diameter of the fixed bed catalytic reactor is 70mm, and the bed thickness of chromium chloride is 2cm.

[0018] The cellulose was fed into the fluidized bed pyrolysis reactor through a two-stage screw feeder, nitrogen was used as the fluidized carrier gas, the pyrolysis reaction temperature was controlled at 420 °C, and the heating rate was 10 4 ℃ / s, after rapid pyrolysis of the raw material, the gas-solid separation is first realized by the cyclone separator, and then the pyrolysis gas enters the fixed-bed catalytic reactor, the catalytic reaction temperature is 380°C, and finally the pyrolysis gas is rapidly condensed to obtain A mixture of water and organic matter. Experiment is carried o...

Embodiment 2

[0020] In the same reaction conditions and reaction environment as in Example 1, only the pyrolysis reaction temperature was changed to 460°C, the experiment was carried out according to the method of Example 1 for 6 minutes, the amount of cellulose was 1 kg, and the collected organic product was 0.22 kg, the calculated organic liquid yield is 46% (percentage by weight), the organic product is analyzed by GC / MS, and the content of L-glucosone determined by GC is 48% (percentage by weight).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com