Method for preparing zinc sulfide aluminium: copper, europium and erbium overlength afterglow luminescent powder

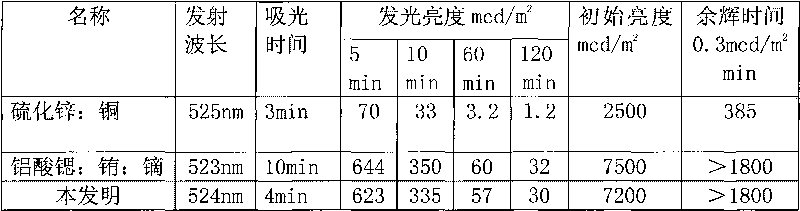

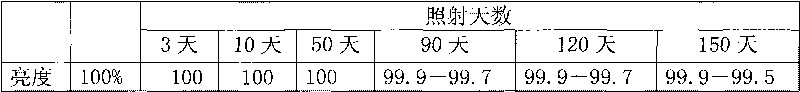

A technology of zinc sulfide and luminescent powder, which is applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of incomparable brightness and afterglow time, poor stability of ultraviolet radiation resistance, and inability to be widely used, so as to prolong afterglow time and improve Stability against ultraviolet radiation, effect of increasing ability to store light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Premix: 100kg of high-purity plasma crystal zinc sulfide powder with a concentration of 160g CuCl 2 CuCl / 1000ml water 2 Solution 1400ml, concentration 15g EuCl 3 EuCl / 1000ml water 3 Solution 300ml, concentration is 4g ErCl 3 ErCl / 1000ml water 3 Solution 65ml and concentration 60g EuCl 3 100ml of LiCl solution per 1000ml of water, after mixing evenly, transfer to a drying box, temperature control 115 ℃, dry for 8 hours, and make the mixture;

[0054] (2) Hammer mill: After the dried mixture is naturally cooled to room temperature, it is transferred to a hammer mill, and then Al with a purity of 99.0% is added. 2 o 3 19kg of SrCl with a purity of 99.0% 2 5kg and Mg with a purity of 99.0% (BO 2 ) 2 1kg, carry out hammer milling, after mixing evenly, make charge;

[0055] (3) Roasting: Transfer the uniformly mixed charge into a quartz crucible to cover and seal it, then put it into a high-temperature roasting furnace, the temperature is controlled at 1100°C, a...

Embodiment 2

[0069] (1) Premix: 100kg of high-purity plasma crystal zinc sulfide powder with a concentration of 80g CuCl 2 CuCl / 1000ml water 2 Solution 1200ml, concentration 3g EuCl 3 EuCl / 1000ml water 3 Solution 200ml, concentration 1g ErCl 3 ErCl / 1000ml water 3 30ml of the solution and 60ml of the LiCl solution with a concentration of 15g LiCl / 1000ml of water are mixed evenly, then transferred to a drying oven, the temperature is controlled at 120°C, and dried for 8 hours to obtain a mixture;

[0070] (2) Hammer mill: After the dried mixture is naturally cooled to room temperature, it is transferred to a hammer mill, and then Al with a purity of 99.0% is added. 2 o 3 15kg of SrCl with a purity of 99.0% 2 3kg and Mg with a purity of 99.0% (BO 2 ) 2 0.5kg, carry out hammer mill, after mixing evenly, make charge;

[0071] (3) Roasting: Transfer the uniformly mixed charge into a quartz crucible to cover and seal it, and then put it into a high-temperature roasting furnace with the t...

Embodiment 3

[0085] (1) Premix: 110kg of high-purity plasma crystal zinc sulfide powder with a concentration of 100g CuCl 2 CuCl / 1000ml water 2 Solution 1500ml, concentration 10g EuCl 3 EuCl / 1000ml water 3 Solution 150ml, concentration is 2g ErCl 3 ErCl / 1000ml water 3 20ml of the solution and 80ml of the LiCl solution with a concentration of 30g LiCl / 1000ml of water are mixed evenly, then transferred to a drying oven, controlled at a temperature of 118°C, and dried for 7 hours to obtain a mixture;

[0086] (2) Hammer mill: After the dried mixture is naturally cooled to room temperature, it is transferred to a hammer mill, and then Al with a purity of 99.0% is added. 2 o 3 10kg of SrCl with a purity of 99.0% 2 1kg and Mg with a purity of 99.0% (BO 2 ) 2 0.1kg, carry out hammer milling, after mixing evenly, make charge;

[0087] (3) Roasting: Transfer the evenly mixed charge into a quartz crucible to cover and seal it, and then put it into a high-temperature roasting furnace with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com