Borate red fluorescent powder for colored plasma panel display and manufacturing method thereof

A red phosphor, plasma technology, applied in borates, chemical instruments and methods, luminescent materials, etc., can solve the problems of high production cost, low production efficiency, complexity, etc., and achieve a simple manufacturing process, easy operation, and production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

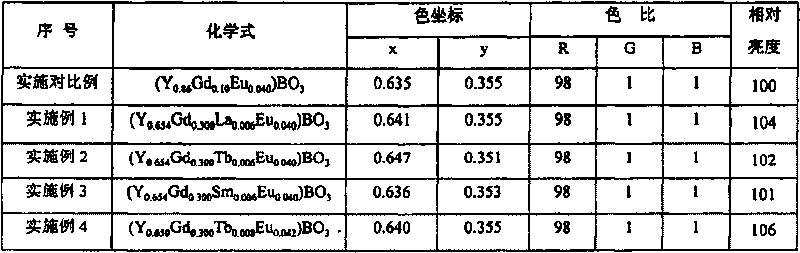

Embodiment 1

[0031] The chemical formula of the borate red phosphor product excited by the vacuum ultraviolet rays of embodiment 1 is (Y 0.654 Gd 0.300 La 0.006 Eu 0.040 )BO 3 , wherein, x=0.040, y=0.006, z=0.300, M is La. . The manufacturing method is the same as that of the comparative example.

Embodiment 2

[0032] The chemical formula of the borate red phosphor product excited by the vacuum ultraviolet rays of embodiment 2 is (Y 0.654 Gd 0.300 Tb 0.006 Eu 0.040 )BO 3 , where x=0.040, y=0.006, z=0.300, M is Tb. . The manufacturing method is the same as that of the comparative example.

Embodiment 3

[0033] The chemical formula of the borate red phosphor product excited by the vacuum ultraviolet rays of embodiment 3 is (Y 0.654 Gd 0.300 SM 0.006 Eu 0.040 )BO 3 , where x=0.040, y=0.006, z=0.300, M is Sm. . The manufacturing method is the same as that of the comparative example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com