Battery electrode, preparation method thereof and vanadium redox flow battery comprising same

A battery electrode and electrode technology, which is applied in the direction of battery electrodes, electrode manufacturing, active material electrodes, etc., can solve the problems of conductive porous material matrix shedding, high cost of high-density graphite plates, and restrictions on the popularization of vanadium redox flow batteries. Effects of compactness, good reaction area, and good chemical reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

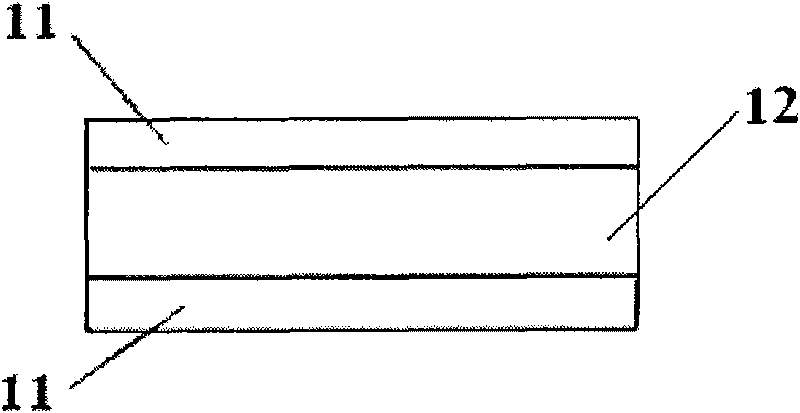

[0025] The method of making at least part of the polymerizable monomer enter the micropores of the partially conductive porous material matrix can be various methods that can be obtained by those skilled in the art in combination with the basic knowledge they have mastered. According to a method of the present invention In a preferred embodiment, the method of allowing at least part of the polymerizable monomer to enter the micropores of the partially conductive porous material matrix includes immersing one side of the conductive porous material matrix in a protective agent, allowing the protective agent to enter one side of the conductive porous material matrix. Then add polymerizable monomers to the conductive porous material matrix, so that at least part of the polymerizable monomers enter the micropores of the conductive porous material matrix, so that the upper layer of the obtained conductive porous material matrix, The middle layer and the lower three layers are respecti...

Embodiment 1

[0076] This example is used to illustrate the battery electrode of the present invention and its preparation method.

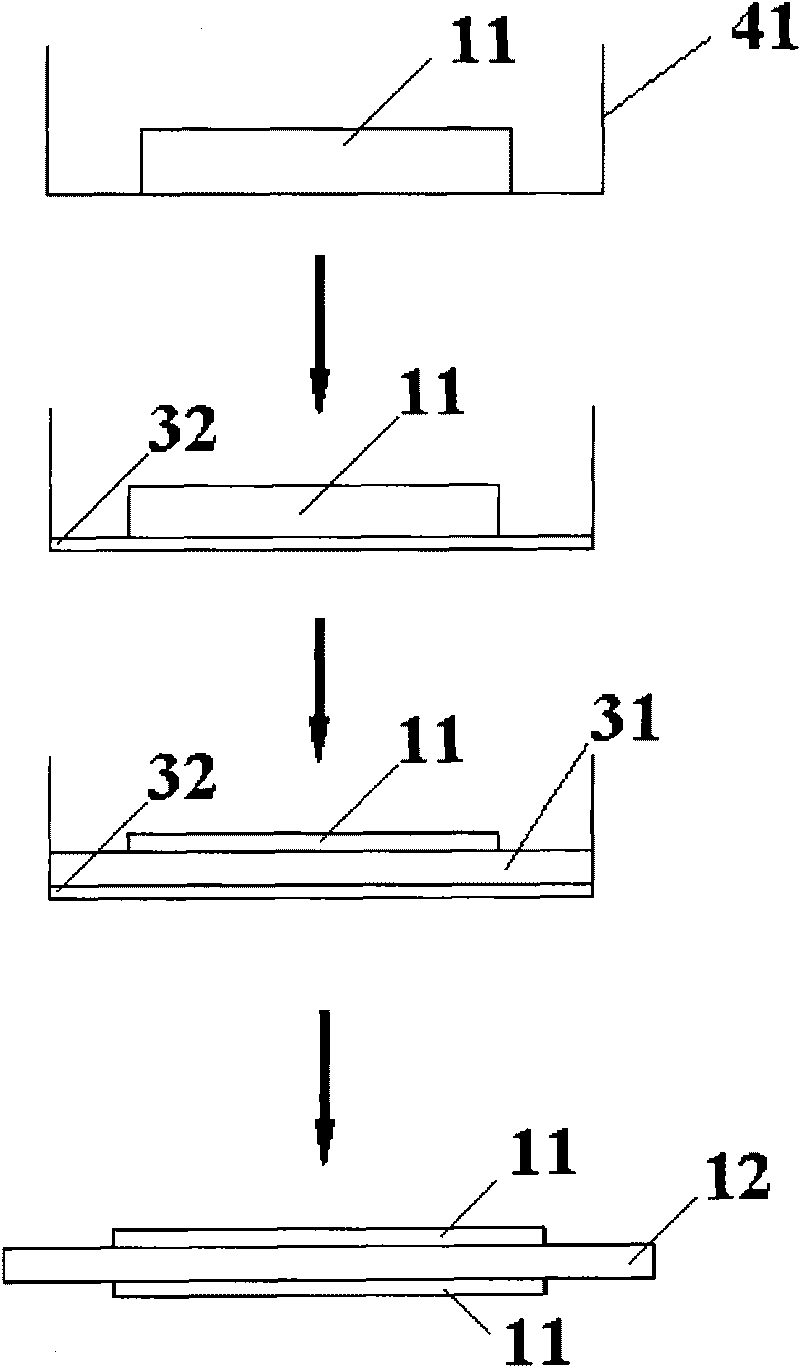

[0077] Equipped with exhaust device, and the size is 34mm×34mm×40mm Figure 4 Add graphite felt with a porosity of 85% in the shown flat-bottomed reactor, wherein the size of the graphite felt is 30mm × 30mm × 8mm; then add fully refined paraffin in the reactor as a protective agent, wherein the melting point of the paraffin is 62 ℃, use an external heater to heat the paraffin to melt it into a liquid state, and soak the graphite felt for 3 minutes to control the depth of the melted paraffin to 2 mm; then remove the heater and gradually lower the temperature to solidify the paraffin into a solid. Then, inject a mixture containing 5% by weight of azobisisobutyronitrile and 95% by weight of styrene monomer into the reactor containing the protective agent and graphite felt, and soak the graphite felt for 6 minutes to control the mixture containing styrene monomer...

Embodiment 2

[0079] This example is used to illustrate the battery electrode of the present invention and its preparation method.

[0080] Equipped with pumping and exhaust devices, and the size is 34mm×34mm×40mm Figure 4 Graphite felt with a porosity of 85% is added in the shown flat-bottomed reactor, wherein the size of the graphite felt is 30mm × 30mm × 8mm; then polyethylene glycol is added to the reactor as a protective agent, wherein the polyethylene glycol The melting point of the polyethylene glycol is 66°C. Use an external heater to heat the polyethylene glycol to melt it into a liquid, and soak the graphite felt for 3 minutes, and control the depth of the melted polyethylene glycol to 2mm; then remove the heater and gradually lower the temperature , to solidify polyethylene glycol into a solid. Then, inject a mixture containing 8% by weight diisopropyl peroxydicarbonate and 92% by weight styrene monomer into the reactor containing the protective agent and graphite felt, and soa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com