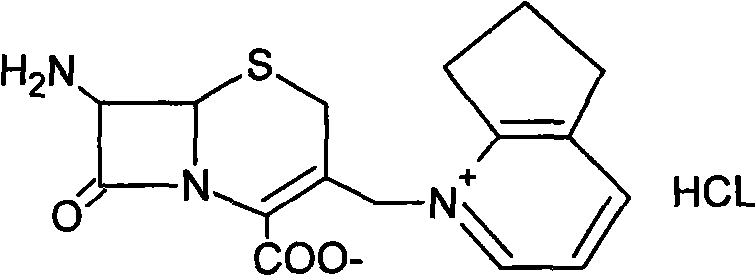

Refining process of 7-ACP.HCL

A 7-ACP and process technology, applied in the field of refining 7-ACP HCl, can solve the problems such as no one has published the purification method of 7-ACP HCl, achieve simple operation procedures and reaction conditions, high yield and high purity , the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the present embodiment, a refining process of 7-ACP·HCl is carried out according to the following steps:

[0026] 1. Add 200ml of deionized water and 50g of crude 7-ACP·HCl into a 1000ml three-necked flask, then add 15% hydrochloric acid solution dropwise, stir and dissolve, so that the pH of the solution is 1.0.

[0027] 2. Add 15ml of 5% hydrogen peroxide to the solution, stir for 15min, add 5g of activated carbon, stir for 30min, filter, wash the carbon with 50ml of deionized water, and combine the washing solution and the filtrate.

[0028] 3. Add 230ml of dichloromethane to the filtrate, stir for 15min, let stand to separate the layers, and separate the water phase.

[0029] 4. Add 500ml of acetone to the water phase, add dropwise 15% ammonia solution while stirring, adjust the pH value to 3.0, stir and crystallize, and grow the crystal for 2 hours after the crystallization is complete.

[0030] 5. Suction filtration, the filtered crystals were washed with 100m...

Embodiment 2

[0033] In the present embodiment, a refining process of 7-ACP·HCl is carried out according to the following steps:

[0034] 1. Add 180ml of deionized water and 45g of crude 7-ACP·HCl into a 1000ml three-necked bottle, then add 20% hydrochloric acid solution dropwise, stir and dissolve, so that the pH of the solution is 0.5.

[0035] 2. Add 10ml of 10% hydrogen peroxide to the solution, stir for 5 minutes, add 5g of activated carbon, stir for 15 minutes, filter, wash the carbon with 50ml of deionized water, and combine the washing solution and the filtrate.

[0036] 3. Add 200ml of dichloromethane to the filtrate, stir for 30min, let stand to separate the layers, and separate the water phase.

[0037] 4. Add 500ml of acetone to the water phase, add dropwise 5% sodium hydroxide solution while stirring, and adjust the pH value to 4.0. The temperature of the solution was cooled to 10°C in a water bath, and the temperature was maintained throughout the crystallization process, and...

Embodiment 3

[0041] In the present embodiment, a refining process of 7-ACP·HCl is carried out according to the following steps:

[0042] 1. Add 550ml of deionized water and 130g of crude 7-ACP·HCl into a 2500ml three-necked bottle, then add 5% hydrochloric acid solution dropwise, stir and dissolve, so that the pH of the solution is 2.0.

[0043] 2. Add 16ml of 15% hydrogen peroxide to the solution, stir for 5 minutes, add 10g of activated carbon, stir for 15 minutes, filter, wash the carbon with 150ml of deionized water, and combine the washing liquid and the filtrate.

[0044] 3. Add 800ml of dichloromethane to the filtrate, stir for 15min, let stand to separate the layers, and separate the water phase.

[0045] 4. Add 1500ml of acetone to the water phase, add 10% sodium carbonate solution dropwise while stirring, adjust the pH value to 2.5, cool the solution to 5°C in a water bath, keep the temperature during the crystallization process, stir to crystallize, and grow crystals for 2 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com