Energy-saving and short-flow manufacturing method of wheel hub with in situ particle reinforced A356 matrix composite material

A manufacturing method and particle-enhancing technology, applied in the field of energy-saving short-process in-situ particle-enhanced A356 alloy wheel manufacturing, can solve the problems of difficult process control, uneven distribution of enhanced particles, easy agglomeration of enhanced particles, etc., to eliminate casting stress, reduce The effect of investment and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

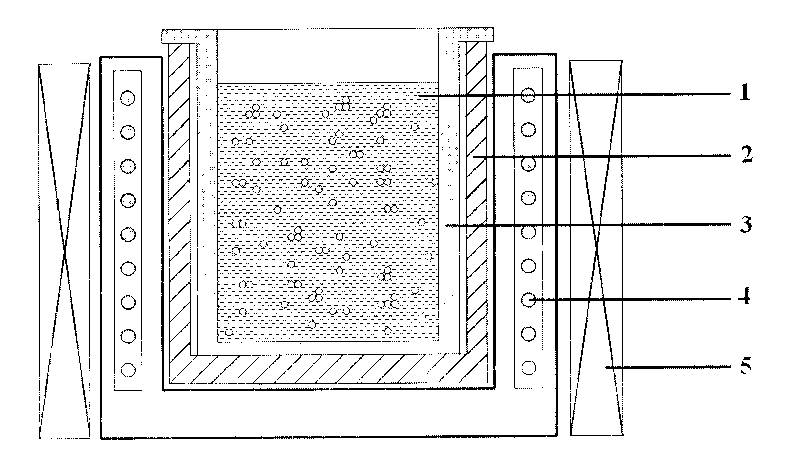

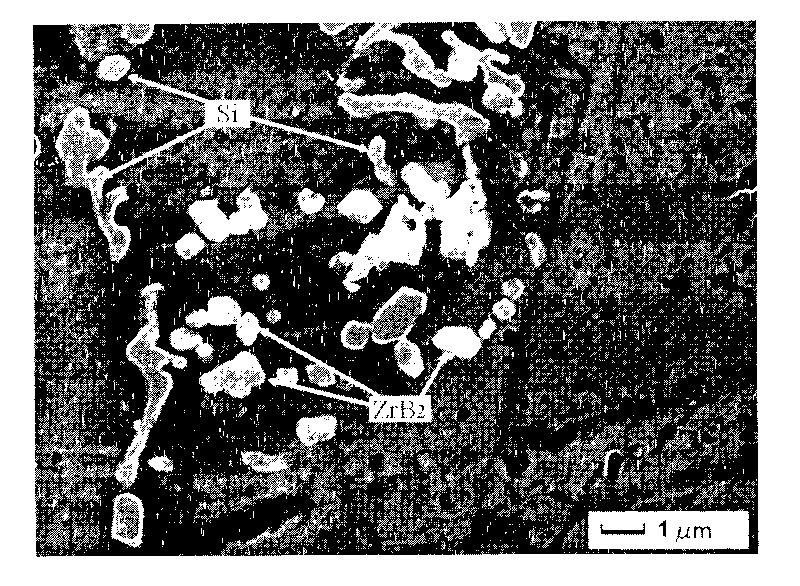

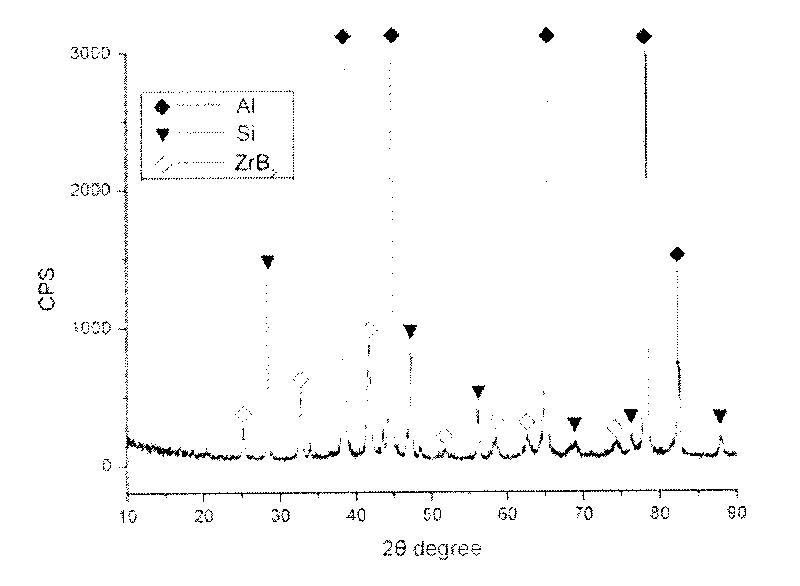

[0029] A356 alloy melt is prepared from pure metal Al, Mg and crystalline silicon by one-time melting, K 2 ZrF 6 and KBF 4 The purity of the powder is 99.9%. Its preparation process is as follows: raw material preparation→in-situ particle melt preparation→modification, refining→pouring, cooling molding→heat treatment. Specifically: first put K 2 ZrF 6 and KBF 4 The powder is baked in a drying oven at 250°C for 3 hours to remove moisture; the pure metal Al, Mg, and crystalline silicon are smelted once to prepare an A356 alloy melt, and overheated to 850°C; then 20% of the mass of the A356 melt ( K2 ZrF 6 +KBF 4 ) powder (wherein K 2 ZrF 6 、KBF 4 The ratio of the powder is 1:1 (mass percentage)) is pressed into the melt in batches with a bell jar; The width is 10ms, and the pulsed magnetic field is applied intermittently for 20 minutes; after the reaction is completed, it is modified and refined, and left to stand for 10 minutes to remove slag; it is poured into a met...

Embodiment 2

[0031] The A356 alloy melt is prepared from pure metal Al and Mg, and crystalline silicon by one-time melting, Zr(CO 3 ) 2 The purity of the powder is 99.9%. Its preparation process is as follows: raw material preparation→in-situ particle melt preparation→modification, refining→pouring, cooling molding→heat treatment. Specifically: Zr(CO 3 ) 2 Put it in an electric oven and raise the temperature to 250°C, keep it warm for 3 hours, fully remove the water, then cool, grind, and sieve through a 70-mesh standard sieve to obtain a powder reaction agent with a particle size of 3 ) 2 Powder (addition amount is 20% of the mass of A356 alloy melt), the pulse magnetic field parameters are: current is 10A, voltage is 550V, frequency is 100kHz, pulse width is 10ms, and the pulse magnetic field action time is intermittently applied for 20min; then carry out metamorphism and refining treatment, stand still for 10min, and remove slag; put it into the holding furnace of the low-pressure c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com