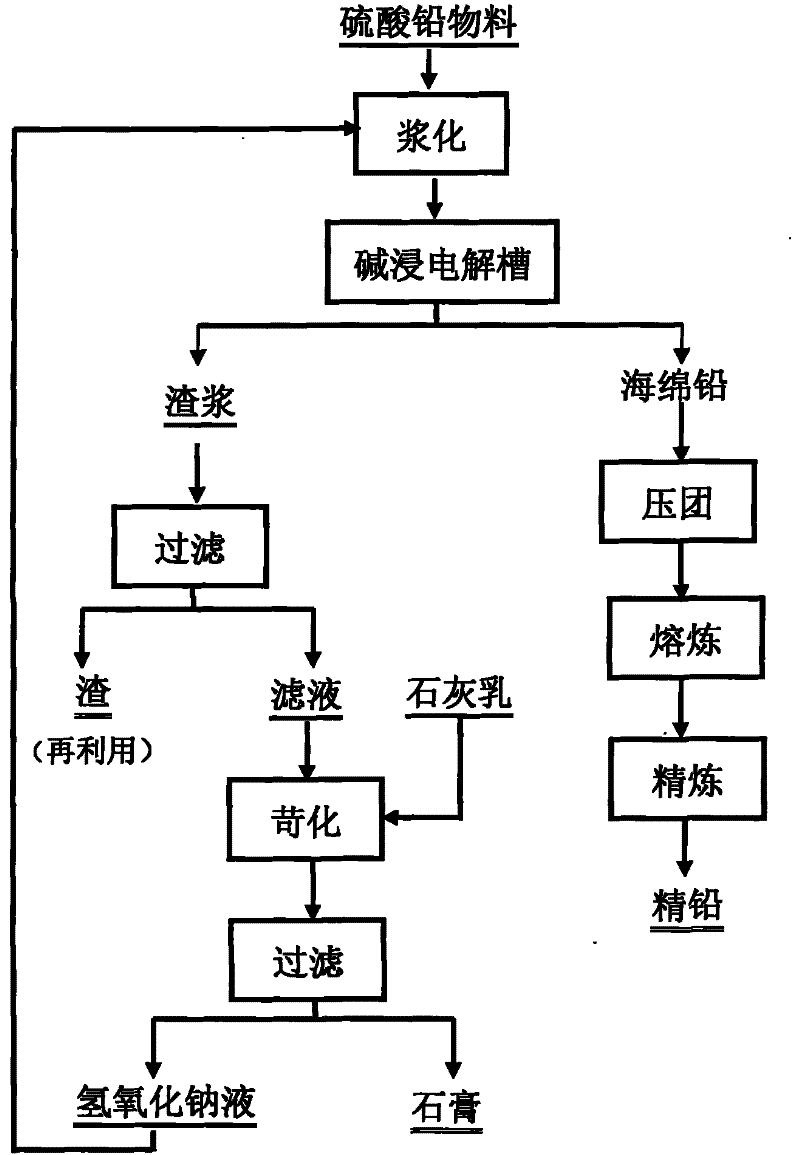

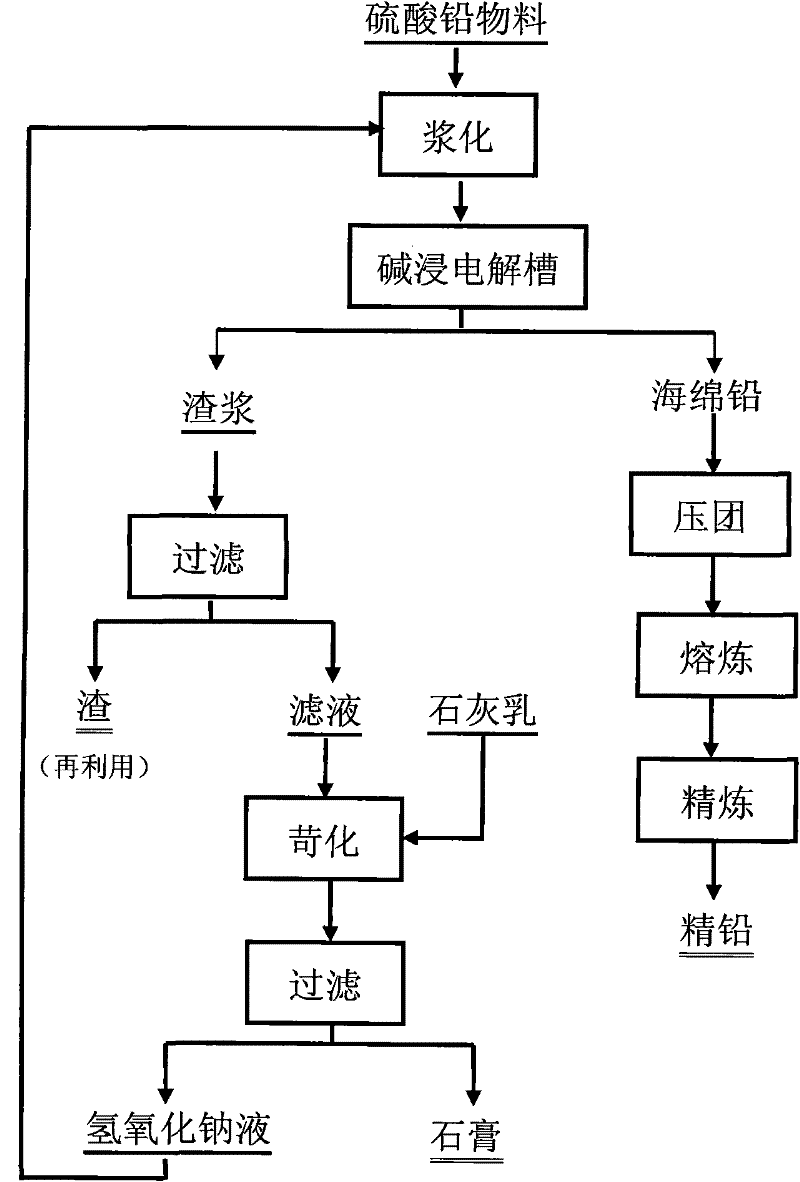

Method for producing lead by executing electrolysis and alkaline leaching on lead sulfate material

A technology of lead sulfate and materials, which is applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of complex structure of solid-phase electrolysis equipment, lengthy process, difficult handling of multi-metal mixed materials, etc., and achieve low alkali consumption, The effect of short process flow and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Using lead-tin sulfate mixed slag as raw material, the composition is (%) Pb 35; Sn 3.80; S 12; Fe 2; SiO 2 5.3; CaO4.

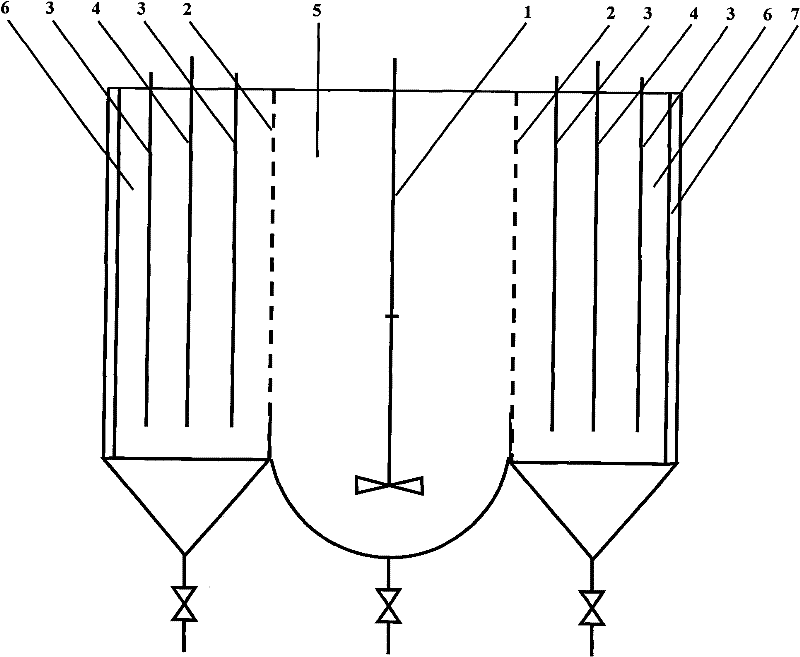

[0032] The electrolytic alkali immersion is carried out in an electrolytic alkali immersion tank with a volume of 20L. The structure of the electrolytic alkali immersion tank is as follows figure 2 shown. The middle of the electrolytic alkali immersion tank is an alkali-dissolving chamber 5, where the material is dissolved in alkali, and the electrolytic chambers 6 at both ends of the tank are used for electrolytic lead deposition and alkali regeneration, and the two chambers are separated by a diaphragm 2.

[0033] The material of the cathode is 304 stainless steel, the cathode is plate-shaped, and the anode is comb-shaped; the diaphragm of the electrolytic alkali immersion tank is acid-resistant fabric, such as polypropylene fiber, polyvinyl chloride fiber, polyester, etc., which can effectively prevent the slurry from penetrating without affecti...

Embodiment 2

[0037] Using plumberite as raw material, the composition is (%): Pb 38; S 9; BaO 5;

[0038] Au 0.0008; Ag 0.08.

[0039] The electrolytic alkali immersion was carried out in an electrolytic cell with a volume of 20 L, and 2 kilograms of material samples were processed each time. The electrolytic cell structure and control conditions were the same as in Example 1. The results of electrolytic alkali leaching are: the output sponge lead is melted and cast into metal lead containing 99.5% of Pb; the recovery rate of lead into metal is 93%, and the leaching slag composition: Pb 5%; Au0.0017%; Ag 0.17%; suitable for It is used as raw material for extracting precious metals gold and silver.

Embodiment 3

[0041] The lead-tin oxide slag produced by crude lead oxidation and tin removal is used as raw material, and the composition is (%):

[0042] Pb 42; Sn 35.

[0043] The electrolytic alkaline immersion is carried out in an electrolytic cell with a volume of 30L, and 3 kilograms of samples are processed each time. The structure of the electrolytic cell and the control conditions are the same as in Example 1. The result of electrolytic alkali leaching is: the output of flaky cathode lead Pb is 99.5%, and the recovery rate of lead metal is 98%. The composition of leaching slag is Sn 65%; Pb 10%; it should be used as raw material for tin smelting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com