Method for increasing molecular weight of polyamide/graphite composite material through solid-phase polymerization

A composite material and solid-state polymerization technology, applied in the field of polymer materials, to achieve good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

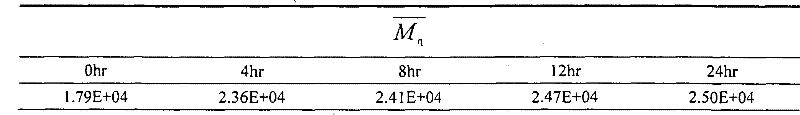

[0023] The nylon 6 / graphite composite material (viscosity-average molecular weight is 1.79E+04) that granular graphite content is 1.5% is added in the reaction flask of rotary evaporator, under vacuum condition (absolute pressure 1torr), under 160 ℃ of conditions, with Sodium hypophosphite is used as a catalyst, and the addition amount is 1.3*10 -5 mol / g, solid-phase polymerization of the reactant, during the reaction, rotate the reaction bottle at 100rpm to fully react. After a certain period of time (respectively 4 hours, 8 hours, 12 hours, 24 hours), the solid-phase polymerized material was placed in pure water at 50° C. and stirred to recover the polyamide / graphite composite material with increased molecular weight.

[0024] The results obtained are as follows:

[0025]

[0026] It can be seen from the results in the table that after 24 hours, the viscosity-average molecular weight of the composite material can be increased from 1.79E+04 to 2.50E+4, while its tensile s...

Embodiment 2

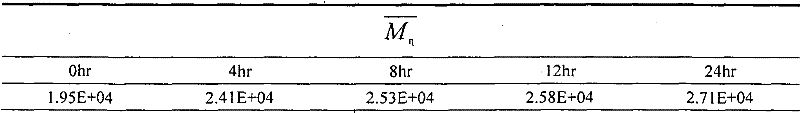

[0028] The nylon 612 / graphite composite material (viscosity-average molecular weight is 1.95E+04) that granular graphite content is 1.5% is added in the reaction flask of rotary evaporator, under vacuum condition (absolute pressure 1torr), under 160 ℃ of conditions, with Sodium hypophosphite is used as a catalyst, and the addition amount is 1.3*10 -5 mol / g, solid-phase polymerization of the reactant, during the reaction, rotate the reaction bottle at 100rpm to fully react. After a certain period of time (respectively 4 hours, 8 hours, 12 hours, 24 hours), the solid-phase polymerized material was placed in pure water at 40° C. and stirred, and the polyamide / graphite composite material with increased molecular weight was recovered.

[0029] The results obtained are as follows:

[0030]

[0031] It can be seen from the results in the table that after 24 hours, the viscosity-average molecular weight of the composite material can be increased from 1.95E+04 to 2.71E+4, and its t...

Embodiment 3

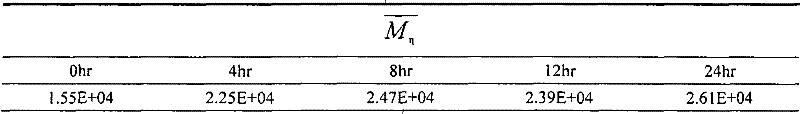

[0033] The nylon 66 / graphite composite material (viscosity-average molecular weight is 1.55E+04) that granular graphite content is 1% is added in the reaction flask of rotary evaporator, under vacuum condition (absolute pressure 1torr), under 160 ℃ of conditions, with Phosphoric acid is used as a catalyst, the addition amount is 1.0*10 -5 mol / g, solid-phase polymerization of the reactant, during the reaction, rotate the reaction bottle at 100rpm to fully react. After a certain period of time (respectively 4 hours, 8 hours, 12 hours, 24 hours), the solid-phase polymerized material was placed in 60°C pure water and stirred to recover the polyamide / graphite composite material with increased molecular weight.

[0034] The results obtained are as follows:

[0035]

[0036] It can be seen from the results in the table that after 24 hours, the viscosity-average molecular weight of the composite material can be increased from 1.55E+04 to 2.61E+4, and its tensile strength can be in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com