Preparation method of high-activity platinum-loaded TiO2 nanotube photocatalyst

A photocatalyst and nanotube technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as reducing catalyst adsorption and ultraviolet light absorption, and avoid bed effects and photocatalytic efficiency. Improve and improve the effect of photon quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

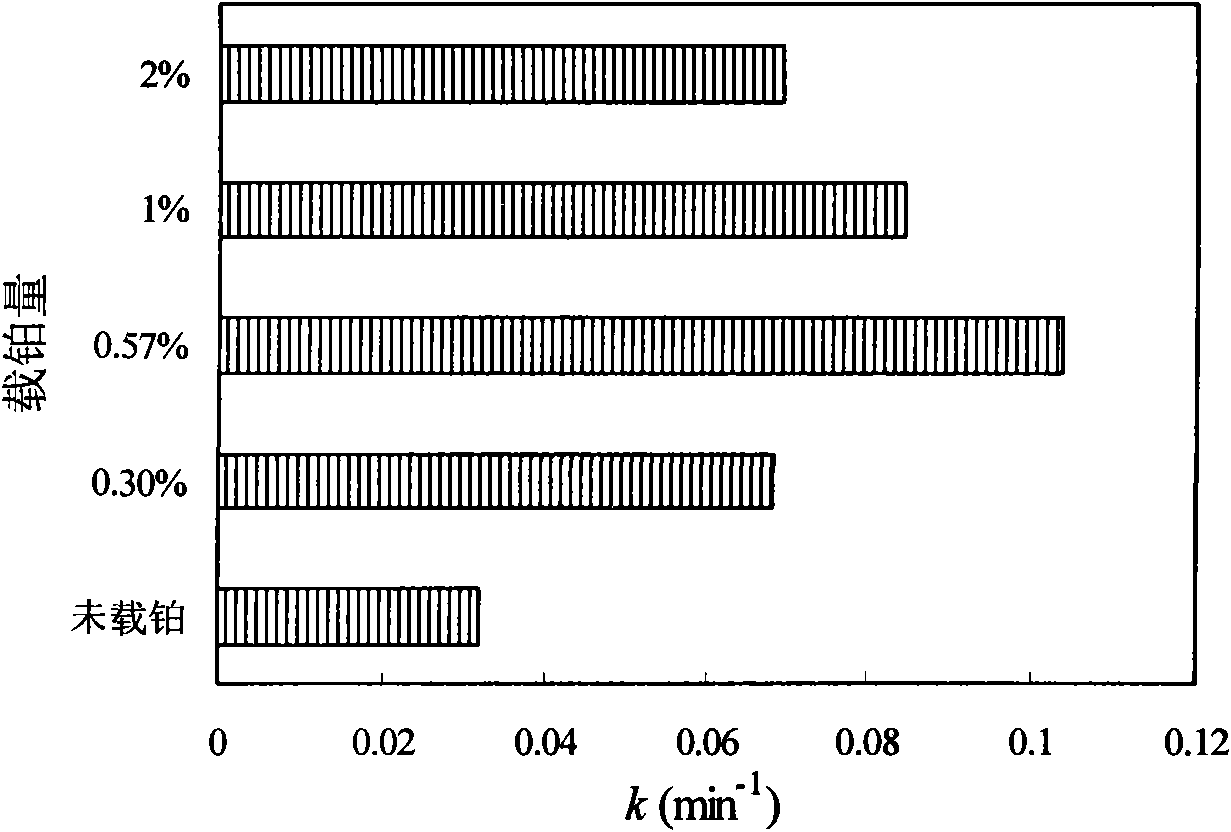

[0014] Highly active platinum-loaded TiO of the present invention 2 The preparation method of nanotube photocatalyst is in the obtained anatase TiO 2 On the basis of nanotubes, the noble metal platinum is selectively deposited on the inner surface of nanotubes by photoreduction deposition method to obtain platinum-loaded TiO with high photocatalytic activity. 2 Nanotube photocatalyst, i.e. platinum-loaded TiO 2 nanotube photocatalyst, is on anatase TiO 2 A highly efficient photocatalyst prepared by depositing platinum on the inner surface of nanotubes. Anatase TiO 2 The nanotubes were synthesized by hydrothermal method, and intermittent milling steps were introduced in the hydrothermal synthesis process to obtain TiO with high purity 2 nanotubes, which are calcined to obtain anatase TiO 2 nanotubes; TiO 2 The platinum on the inner surface of the nanotube is prepared by photoreduction deposition. It mainly includes the following steps:

[0015] (1) Add 1~10gTiO to 10mol...

Embodiment 1

[0022] Weigh 1gTiO 2 Powder, add 40mL of 10mol / L NaOH solution, hydrothermally react in the reactor at 150°C for 5h, then cool to room temperature, grind the solid in the reactor, and then continue to react at the same temperature for 48h to obtain After cooling the sample, adjust the pH value of the mixed solution to 2.5 with hydrochloric acid, pickle it with stirring for 3 hours, wash it with distilled water until it is neutral, then dry it, and then roast it at 500°C for 5h (heating rate: 1°C / min) to obtain Anatase TiO 2 nanotube.

[0023] Anatase TiO 2 Nanotubes as the matrix, add chloroplatinic acid, stir to make it evenly adsorbed on TiO 2 The inner and outer surfaces of the nanotubes are then washed with distilled water to remove the chloroplatinic acid adsorbed on the outer surfaces of the nanotubes, and the amount of platinum loaded on the inner surface of the nanotubes is controlled to be 0.57%, and dried to obtain platinum-loaded TiO 2 Nanotube precursors. Weig...

Embodiment 2

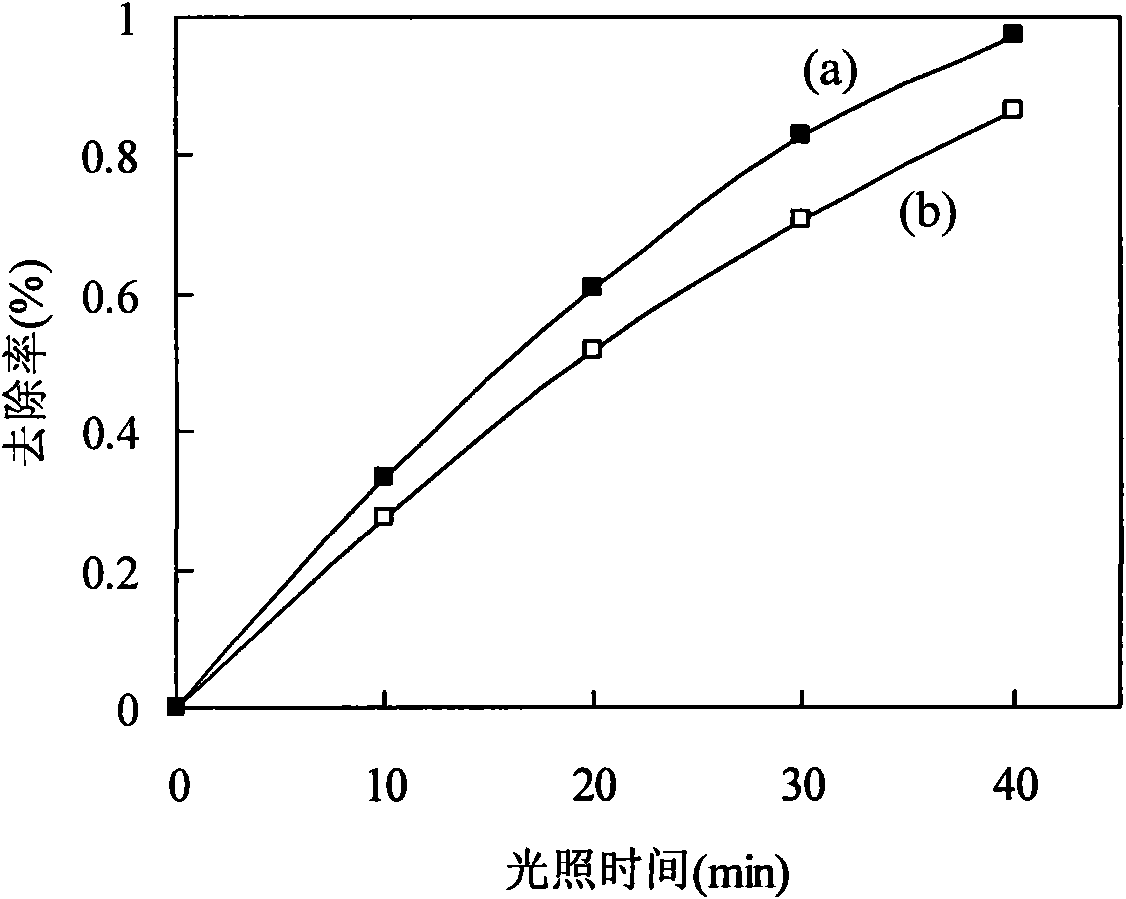

[0027] In Example 1, other conditions remained unchanged, the hydrothermal reaction temperature was changed to 110°C, and the obtained platinum-loaded TiO 2 The removal rate of nanotube photocatalyst to rhodamine B solution is lower than that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com