Method for producing class of norbornene derivative

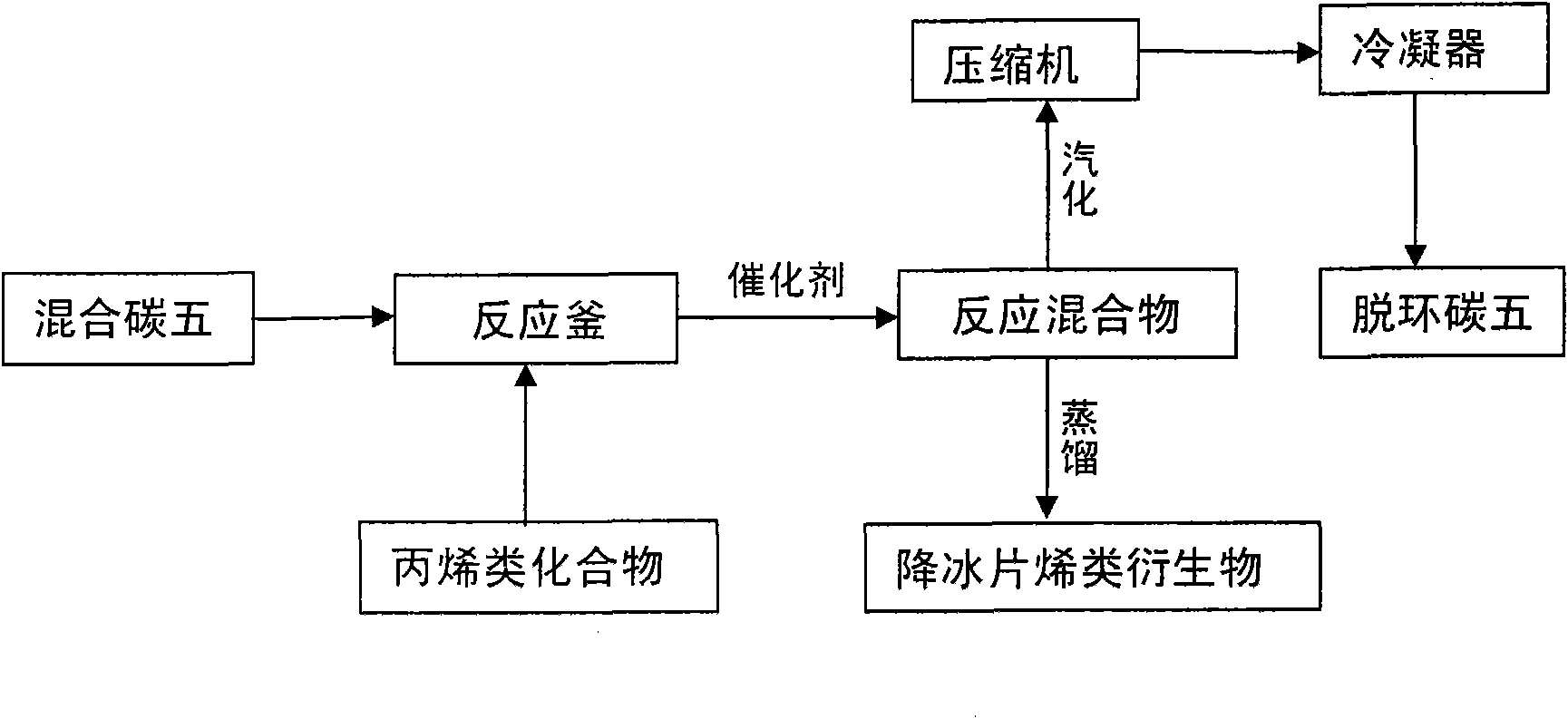

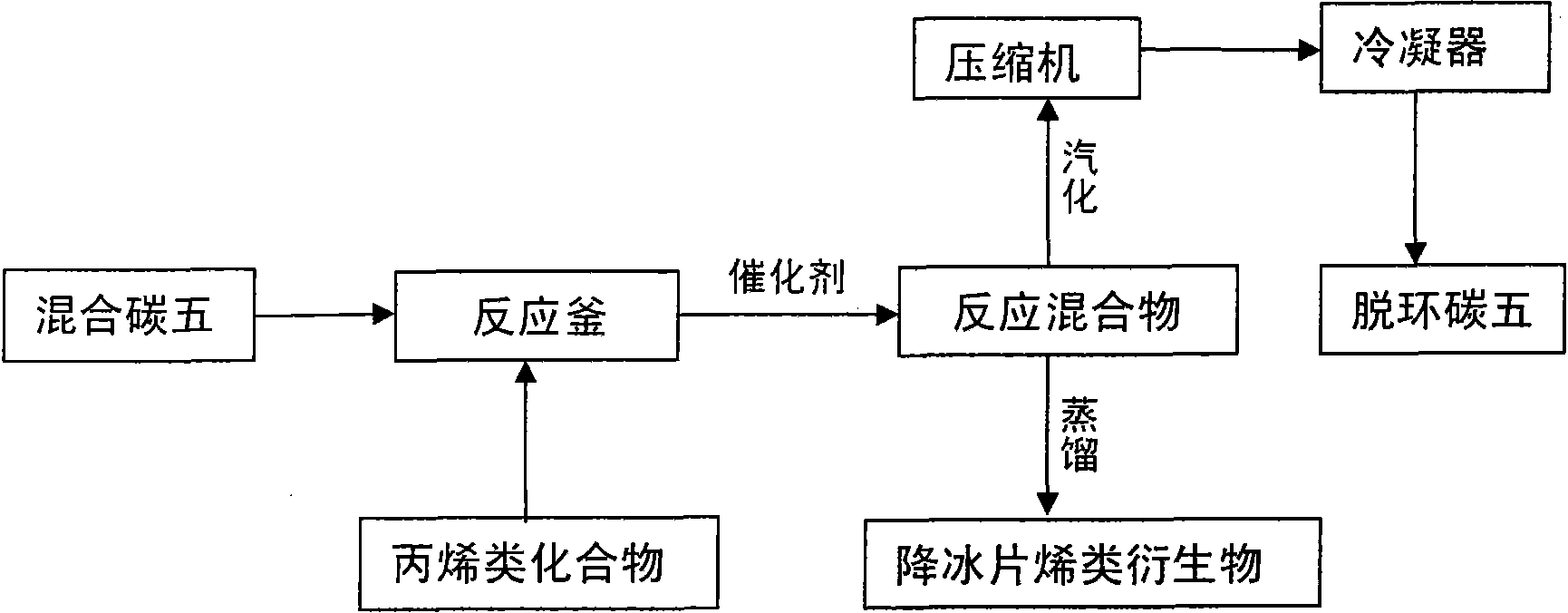

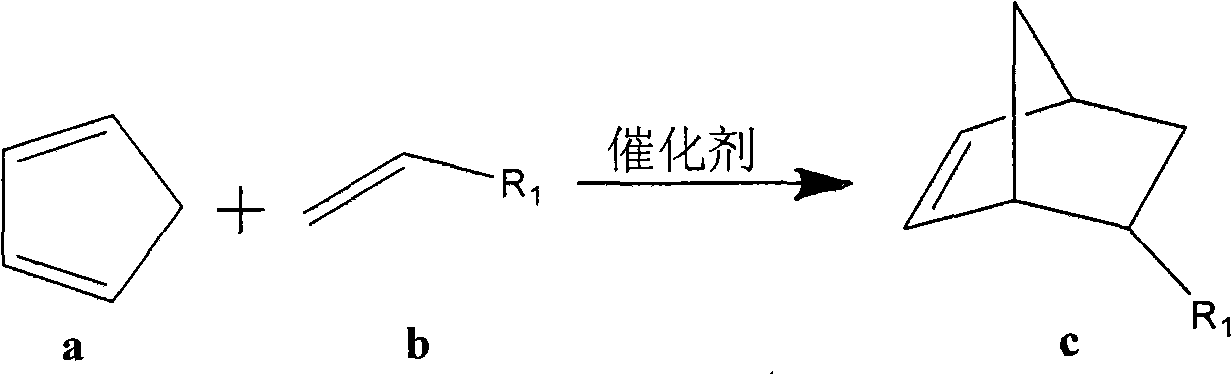

A norbornene and production method technology, applied in the field of organic synthesis, can solve the problems of increasing production costs, affecting the reaction process and product conversion rate, environmental pollution, etc., and achieve the effects of strengthening deep processing and utilization, fully utilizing raw materials, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] At a temperature of 5 °C and stirring, 0.55 g of tert-butylcatechol and 0.11 g of [Cu 2 (dppm) 2 (C 7 H 7 N)(μ-NO 3 )](NO 3 ) mixture, gradually add acrylonitrile, stop the addition when there is no cyclopentadiene detected by GC, and add 80.4 g of acrylonitrile in total. The reaction mixture was vaporized, compressed and condensed to obtain 578.2 g of decyclic Cpenta; the residue was distilled under reduced pressure with an oil pump to obtain 157.2 g of 2-cyano-5-norbornene with a yield of 87.8%.

Embodiment 2

[0018] At a temperature of 0 °C and stirring, 0.13 g of tert-butylcatechol and 0.13 g of [Cu 2 (dppm) 2 (C 7 H 7 N)(μ-NO 3 )](NO 3 ) mixture, gradually add acrylic acid, stop adding when there is no cyclopentadiene detected by GC, and add 131.0 g of acrylic acid in total. The reaction mixture was vaporized, compressed and condensed to obtain 733.7 g of decyclic Cpenta; the residue was distilled under reduced pressure with an oil pump to obtain 211.4 g of 5-norbornene-2-carboxylic acid with a yield of 85.2%.

Embodiment 3

[0020] At a temperature of 2 °C and stirring, 0.40 g of tert-butylcatechol and 0.11 g of [Cu 2 (dppm) 2 (C 7 H 7 N)(μ-NO 3 )](NO 3 ) mixture, gradually add tert-butyl acrylate, stop adding when there is no cyclopentadiene detected by GC, and add 255.9 g of tert-butyl acrylate in total. The reaction mixture was vaporized, compressed and condensed to obtain 770.0 g of decyclic Cpenta; the residue was distilled under reduced pressure with an oil pump to obtain 318.6 g of tert-butyl 5-norbornene-2-carboxylate with a yield of 82.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com