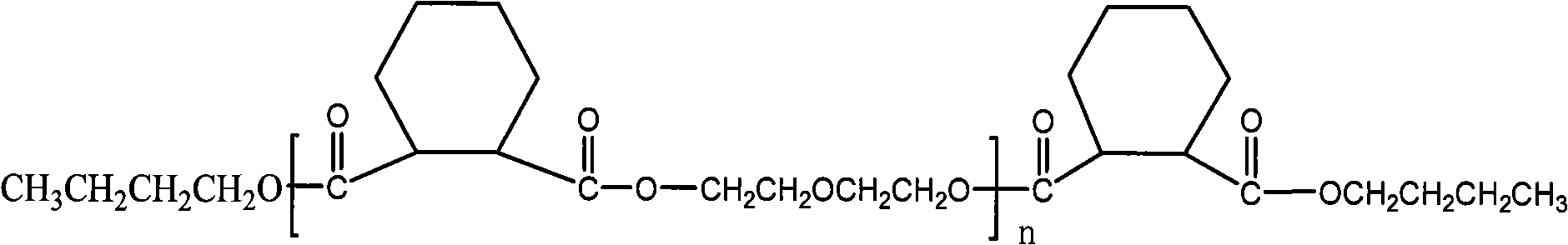

Non-aromatic nucleus structure poly-hexahydrobenzene phthalic anhydride dihydric alcohol ester plasticizer and preparation method thereof

A technology of polyhexahydrophthalic anhydride diethylene glycol ester and hexahydrophthalic anhydride is applied in the field of functional polymer material application assistants, which can solve problems such as carcinogenicity, and achieve the effects of small migration and good product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

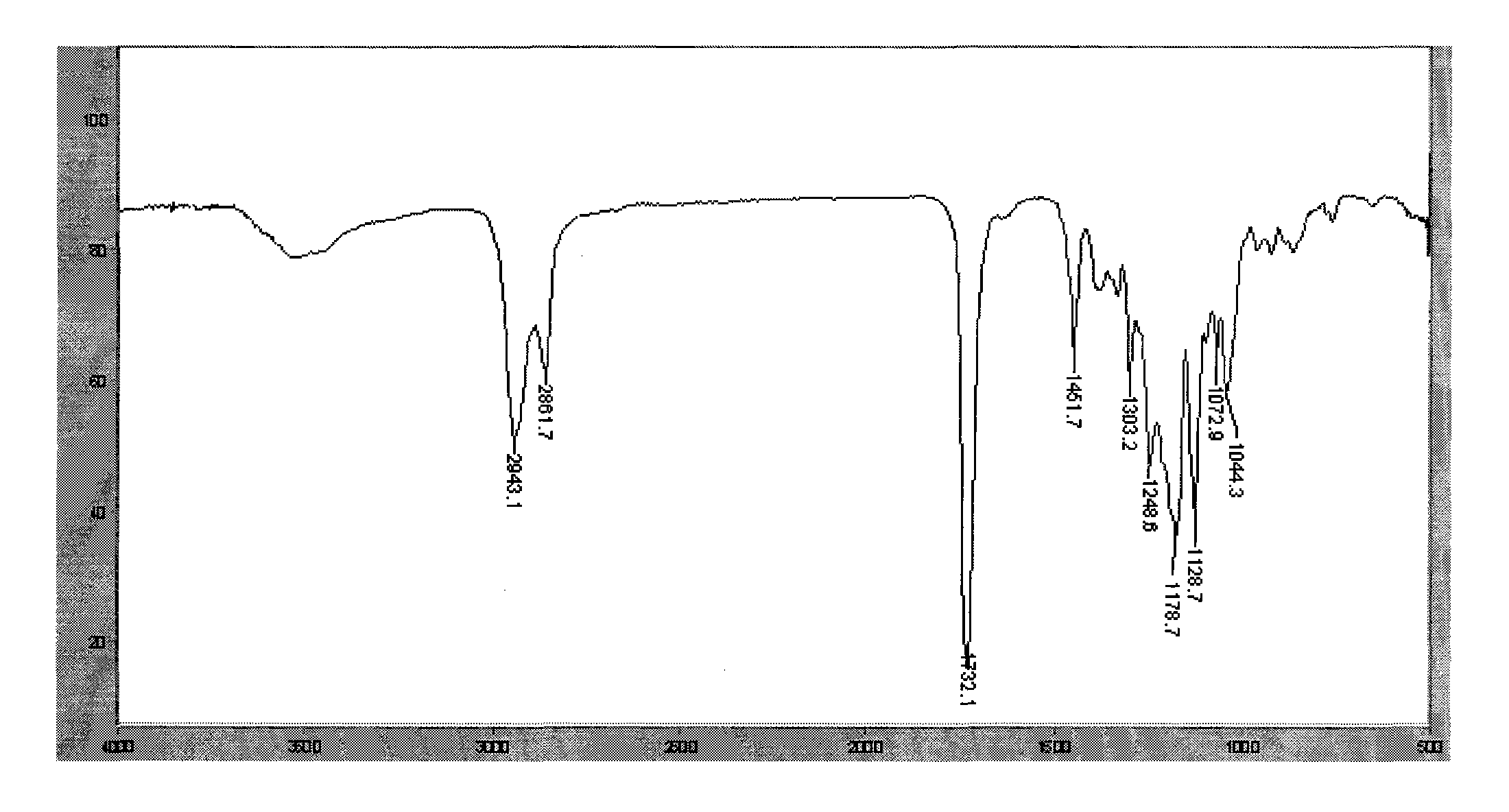

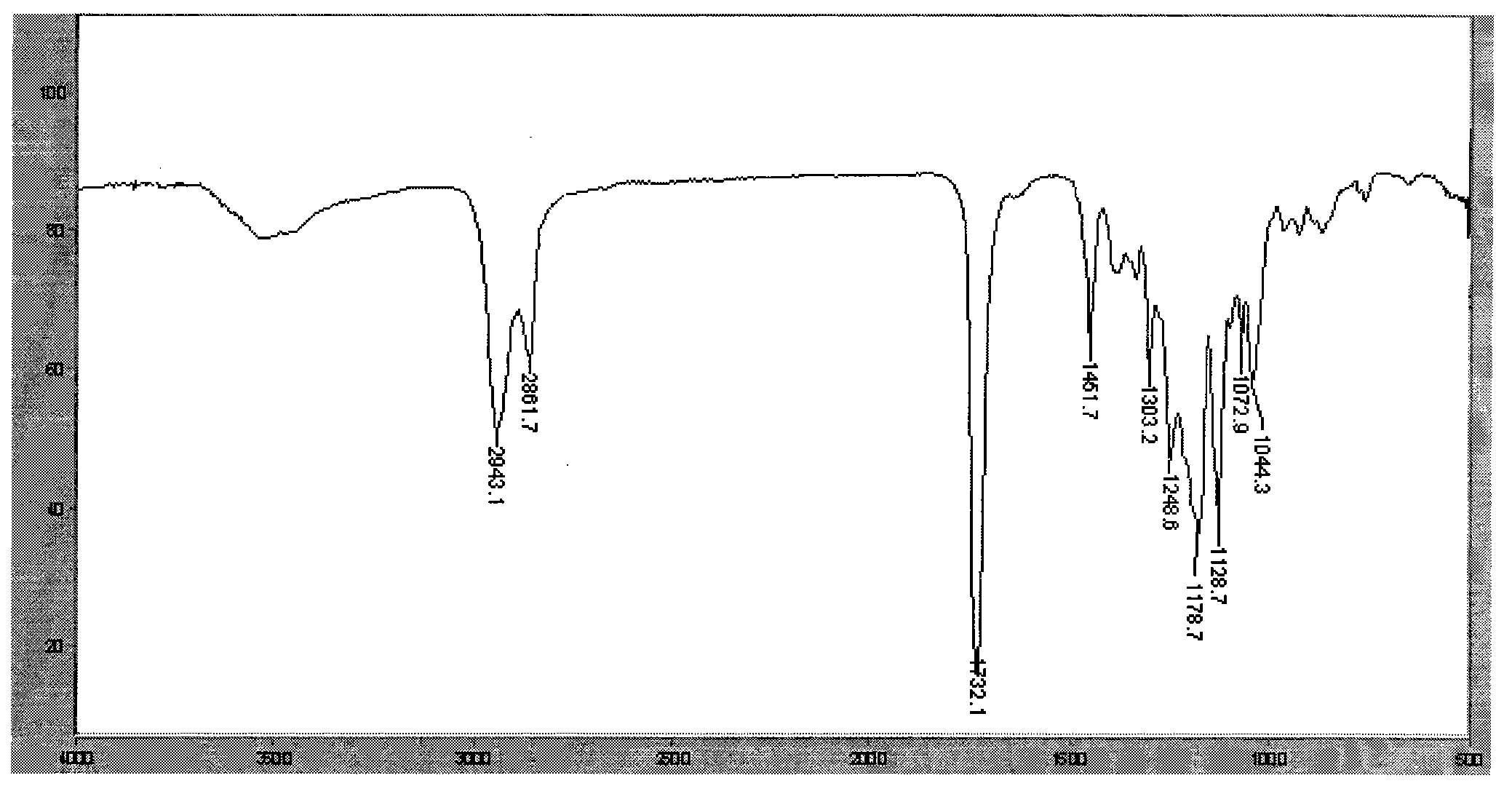

Image

Examples

Embodiment 1

[0020] Add hexahydrophthalic anhydride, diethylene glycol, n-butanol, catalyst tetrabutyl titanate / tetraisopropyl titanate and water-carrying agent cyclohexane and activated carbon raw materials in proportion to the reactor, wherein: hexahydrophthalic anhydride and The mol ratio of diethylene glycol is 1.10: 1, and the mol ratio of n-butanol and hexahydrophthalic anhydride is 0.10: 1, and the addition of tetrabutyl titanate / tetraisopropyl titanate is the molar amount of raw materials (based on the molar amount of hexahydrophthalic anhydride 1‰ of meter). First, feed nitrogen into the system for 20 minutes to drive away the air, heat and stir under normal pressure. Start timing when the temperature rises to 140°C, then heat up, the highest reaction temperature zone is 190°C-200°C, and start timing reaction from 140°C for 5~ After 6 hours, cool slightly, switch the system to decompression reaction, gradually reduce the pressure to a residual pressure of 0.04Mpa under water vapor...

Embodiment 2

[0024] Add hexahydrophthalic anhydride, diethylene glycol, isobutanol, catalyst tetrabutyl titanate / tetraisopropyl titanate and water-carrying agent cyclohexane and activated carbon raw materials in proportion to the reaction kettle, wherein: hexahydrophthalic anhydride and The mol ratio of diethylene glycol is 1.10: 1, and the mol ratio of isobutanol and hexahydrophthalic anhydride is 0.10: 1, and the addition of tetrabutyl titanate / tetraisopropyl titanate is the molar amount of raw materials (based on the molar amount of hexahydrophthalic anhydride 5‰ of the measuring meter). Firstly, nitrogen gas is introduced into the system for 20 minutes to get rid of the air, and heated and stirred under normal pressure. When the temperature rises to 140°C, the timing starts, and then the temperature rises. The highest reaction temperature zone is 190°C-200°C. Start timed reaction at 140°C for 5-6 hours, cool down slightly, switch the system to decompression reaction, gradually reduce th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com