Group iii nitride semiconductor epitaxial substrate

A nitride semiconductor and epitaxial substrate technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, from chemically reactive gases, etc., can solve problems such as insufficient crystal quality and difficult crystal growth, and achieve improved crystal quality. The effect of suppressing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

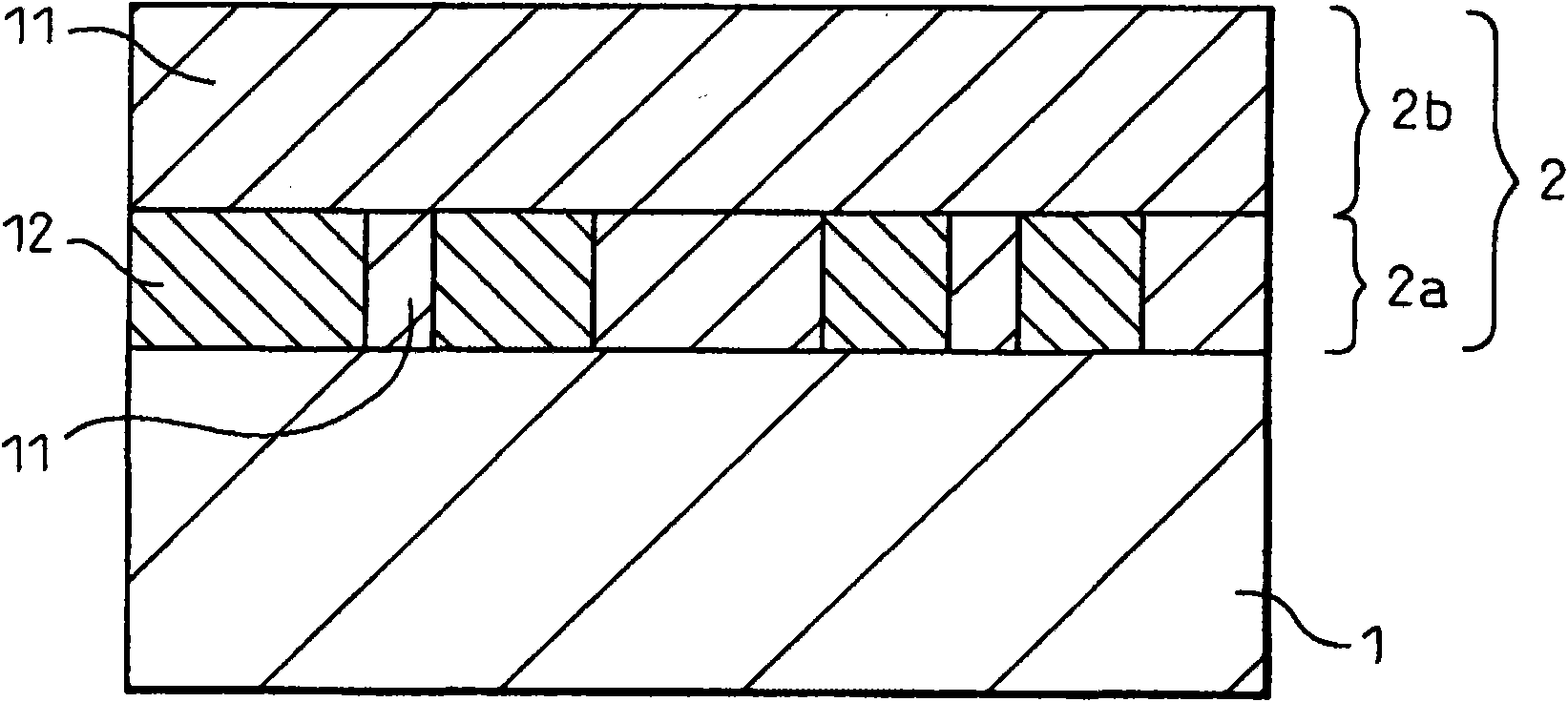

[0066] figure 1 It is a diagram schematically showing a cross-sectional structure of a Group III nitride semiconductor epitaxial substrate of the present invention in which AlN is laminated on a sapphire substrate produced in this example. In the figure, 1 is the substrate. 2 is Al x Ga 1-x The N (0≤x≤1) layer is composed of a layer 2a in which -C polar crystals and +C polar crystals are mixed, and a layer 2b in which only +C polar crystals exist. 11 is a +C polar crystal, and 12 is a -C polar crystal.

[0067] A structure in which AlN is laminated on a sapphire substrate is formed by the following procedure using a general reduced-pressure MOVPE device. First, a Φ2-inch (0001) sapphire substrate is loaded on a molybdenum suscepter. This was installed in a water-cooled reaction furnace using stainless steel through a load-lock chamber, and the furnace was cleaned by flowing nitrogen gas.

[0068] After changing the flowing gas in the vapor phase growth reaction furnace t...

Embodiment 2

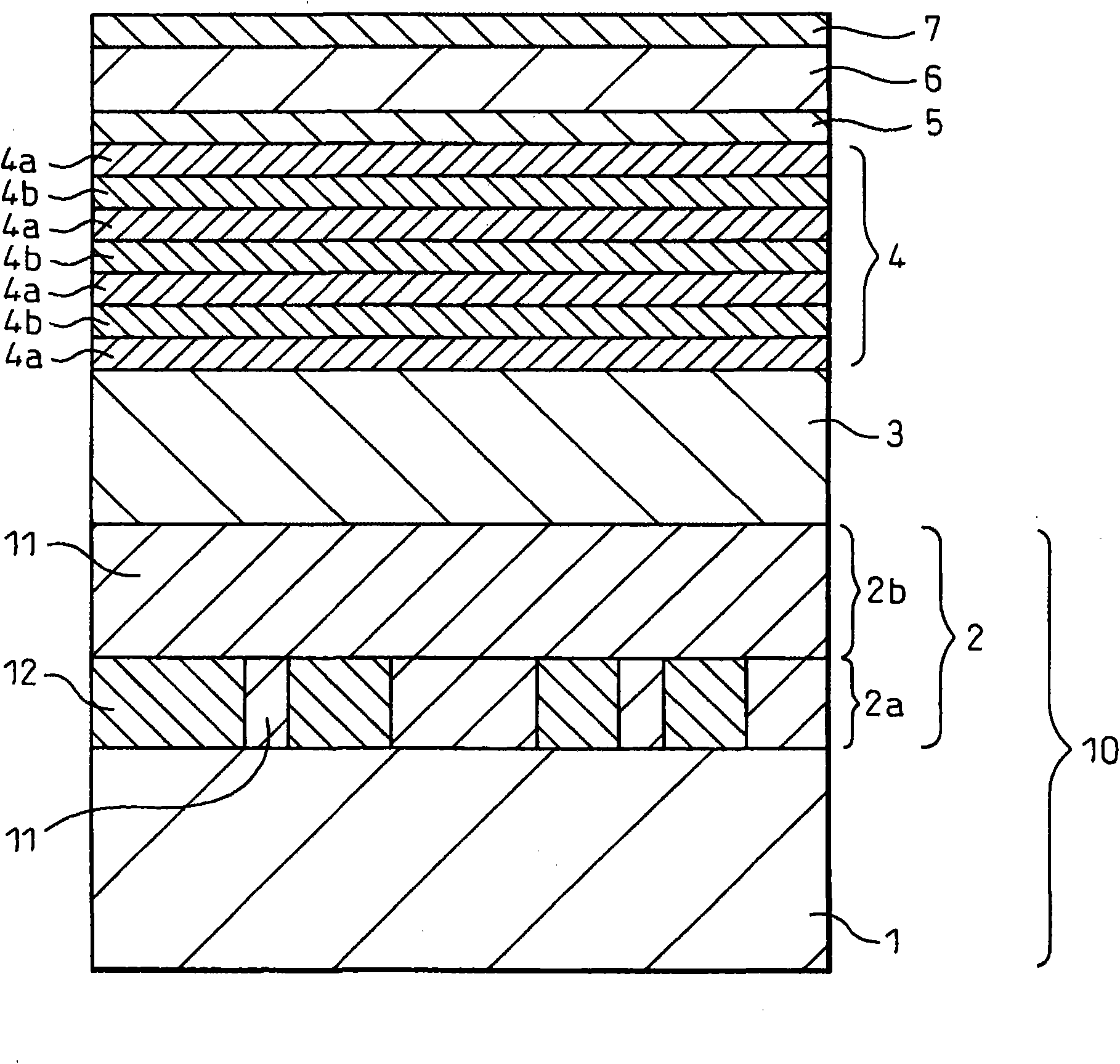

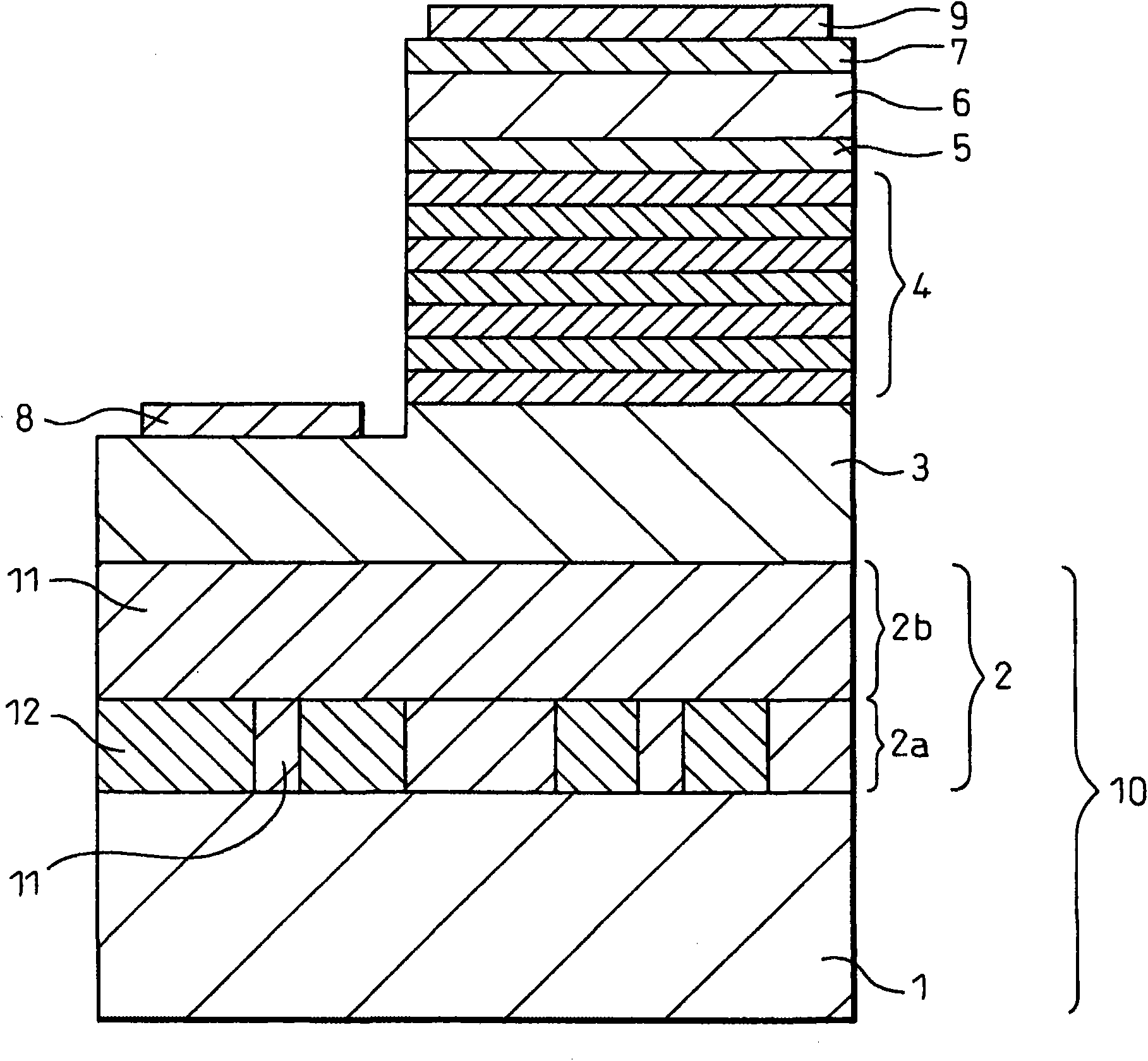

[0077] Fabricated on the Group III nitride epitaxial substrate of the present invention produced in Example 1 figure 2 A semiconductor stacked structure showing a cross-sectional structure in . In the figure, 1 and 2 with figure 1 Again, 1 is the base material, 2 is Al x Ga 1-x The N (0≤x≤1) layer is composed of a layer 2a in which -C polar crystals and +C polar crystals are mixed, and a layer 2b in which only +C polar crystals exist. 11 is +C polar crystal, 12 is -C polar crystal, 3 is Al 0.25 Ga 0.75 N(Si)n-capping layer, 4 is the MQW active layer, made of Al 0.12 Ga 0.88 N barrier layer 4a and Al 0.04 Ga 0.96 N well layer 4b. 5 is Al 0.35 Ga 0.65 N(Mg)p-electron blocking layer, 6 is Al 0.25 Ga 0.75 N(Mg)p-cladding layer, 7 is GaN(Mg)p-contact layer. 10 is an AlN pattern substrate of the present invention.

[0078] The production method is to fix the AlN epitaxial substrate produced in Example 1 in the reaction furnace again by the same operation as in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com