Method for separating and extracting L-ribose

A ribose and arabinose technology, applied in the field of separation of biochemical products, can solve problems such as inability to crystallize products, lower economic and social benefits, and cumbersome process operations, so as to improve product purity and yield, reduce production costs, yield and The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

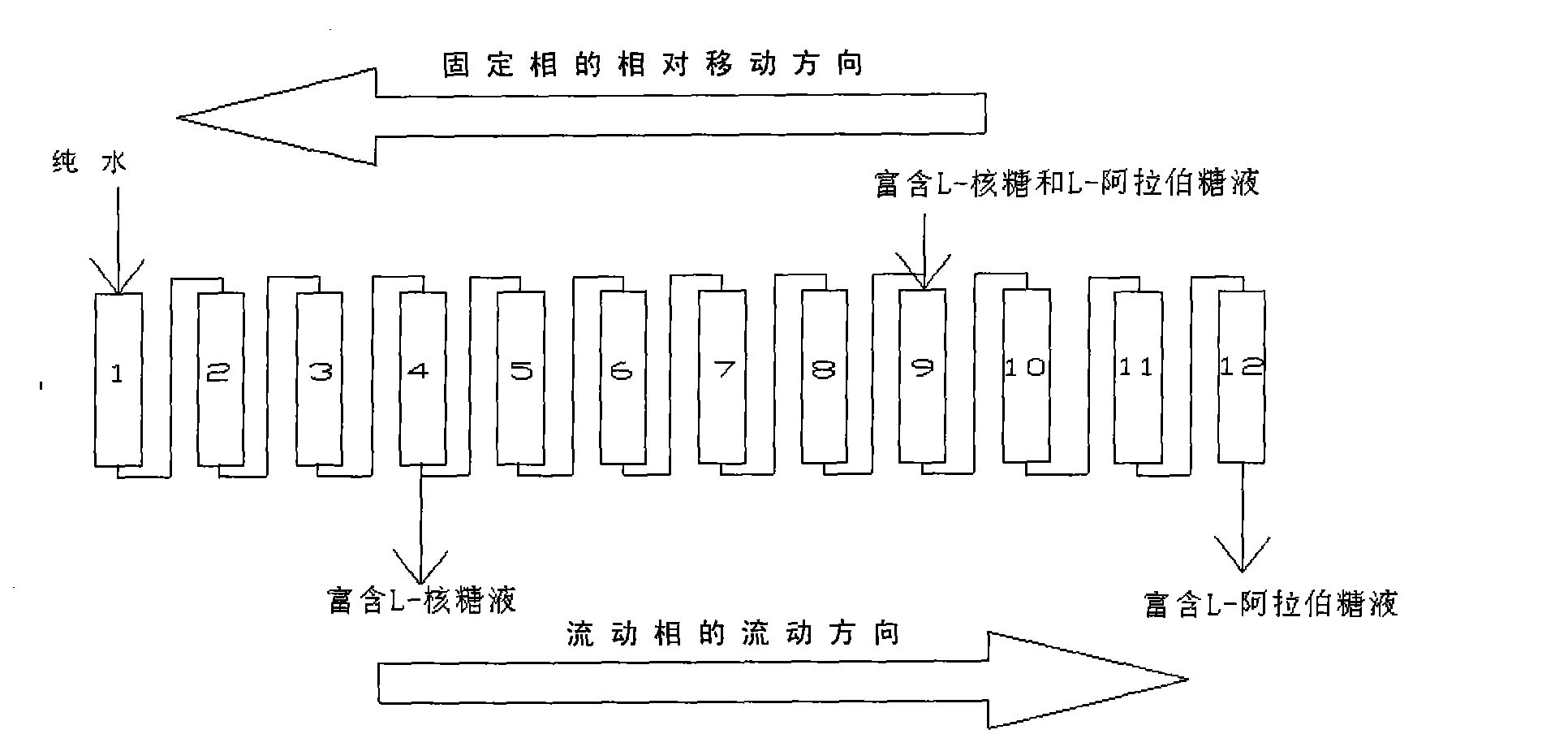

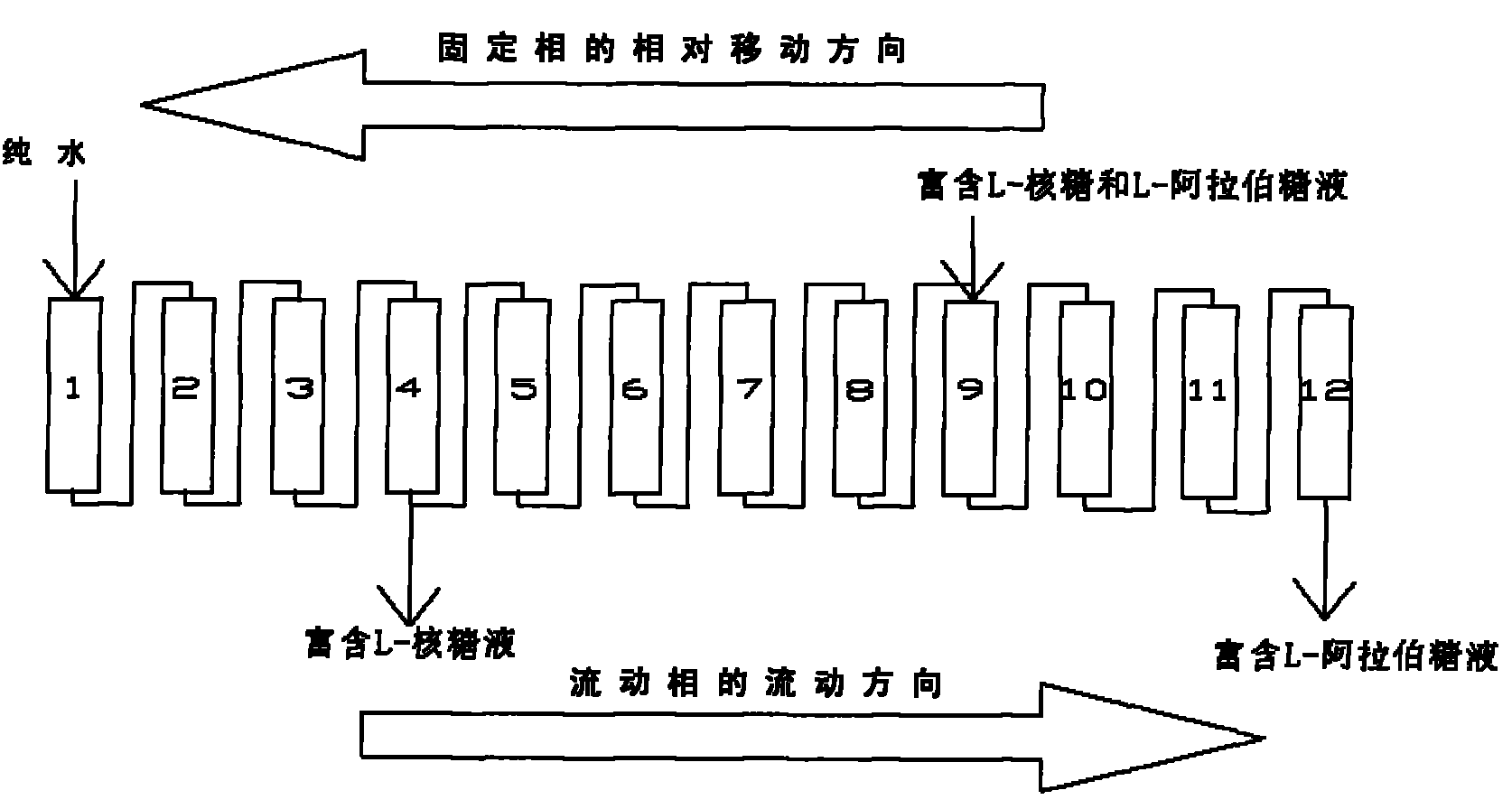

Method used

Image

Examples

Embodiment 1

[0029] 1) Take 20L of the reaction solution of L-arabinose to synthesize L-ribose, and carry out continuous centrifugation at a speed of 3000r / min until no more liquid is centrifuged out;

[0030] 2) The solution obtained after centrifugation was chromatographed with D318 macroporous weakly basic anion exchange resin, the resin loading was 42L, and the resin layer height was 1.5m, and eluted with water;

[0031] The obtained Ionic solution: L-ribose content is 11.87%, purity is 37.04%, xylose content is 24.60%, L-arabinose content is 10.32%, dry matter content is 32.05%, dark green.

[0032] 3) Take 26L of the ionizing liquid after the chromatography, start the simulated moving bed sample injection treatment, adjust the water inlet rate to be 51.66ml / min, the sample injection rate to be 11.48ml / min, the waste water outflow rate to be 51.66ml / min, and the product to flow out. The rate was 11.48ml / min, the backfill rate was 40.18ml / min; the resulting 35.58L L-ribose-rich solutio...

Embodiment 2

[0035] 1) Take 26L of the ionizing solution after the chromatography in Example 1, open the simulated moving bed sample injection treatment, adjust the water inlet rate to be 45.92ml / min, the sample injection rate to be 8.61ml / min, and the waste water outflow rate to be 45.92ml / min. min, the product outflow rate was 8.61ml / min, and the backfill rate was 34.44ml / min; the obtained 36.90L L-ribose-rich solution was light yellow, the L-ribose content was 8.28%, the dry matter was 10.19%, and the purity was 81.2% , the recovery rate of L-ribose was 99%;

[0036] 2) Concentrating and crystallizing the solution rich in L-ribose to obtain L-ribose, and the crystal purity of L-ribose is increased to 99.1%.

Embodiment 3

[0038] 1) Take 26L of the ionizing solution after the chromatography in Example 1, open the simulated moving bed sample injection treatment, adjust the water inlet rate to be 57.40ml / min, the sample injection rate to be 17.22ml / min, and the waste water outflow rate to be 57.40ml / min. min, the product outflow rate was 17.22ml / min, and the backfill rate was 45.92ml / min; the obtained 34.9L L-ribose-rich solution was light yellow, the L-ribose content was 8.14%, the dry matter was 9.01%, and the purity was 90.3% , the recovery rate of L-ribose was 92%;

[0039] 2) Concentrating and crystallizing the solution rich in L-ribose to obtain L-ribose with a purity of 95.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com