Application of zinc glutamate and derivatives thereof as animal feed additive for promoting growth

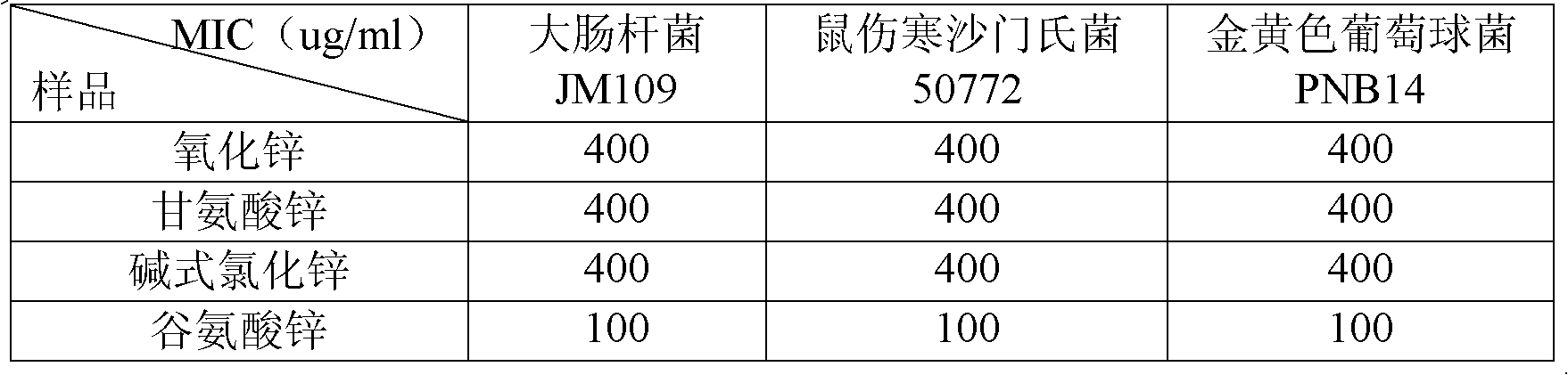

A feed additive, zinc glutamate technology, applied in animal feed, animal feed, application, etc., can solve the problems of low water solubility, poor solubility and acid resistance, and achieve low water solubility, high bioavailability, and pollution reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Synthesis of zinc glutamate:

[0023] A. Preparation of 10% sodium glutamate solution: Weigh 100 grams of sodium glutamate (chemically pure) and dissolve it in 1000 ml of water;

[0024] B. Preparation of 14.38% zinc sulfate solution: the exact amount of 143.8 grams of zinc sulfate heptahydrate (chemically pure) is dissolved in 1000ml of water;

[0025] C. Mix 1000ml each of 10% sodium glutamate solution and 14.38% zinc sulfate solution, then adjust the pH value of the aforementioned mixed solution to 7.0 with NaOH solution, stir and react at room temperature for 2 hours, centrifuge, take the precipitate, and wash with water suspension centrifugation Precipitation was carried out for 3 times, followed by drying at 100° C. to constant weight to obtain 116.64 g of zinc glutamate with a yield of 96.09%.

[0026] (2) measure respectively the content of glutamic acid and zinc ion of the zinc glutamate obtained in step (1):

[0027] A. Determination of zinc ion content:...

Embodiment 2

[0118] Growth-promoting effect of different derivatives of zinc glutamate on animals

[0119] (1) Preparation of Different Zinc Glutamate Derivatives

[0120] A. Zinc glutamate hydrochloride: Weigh 100 grams of ZnCl 2 and 137.3 grams of sodium glutamate were dissolved in 1000ml of water, respectively, stirred until completely dissolved, mixed the two, adjusted the pH value of the mixed solution to 4.0 with 0.1M hydrochloric acid solution, heated and continuously stirred for the reaction, and harvested the crystals. Dry to constant weight. Dissolve the product with 1 gram of water and dilute to 100 ml, and measure the content of zinc ion (atomic absorption method), chloride ion (Moire method) and glutamic acid (amino acid analyzer) in the solution. Results The zinc ion concentration was 2.692 mg / ml, the chloride ion content was 1.470 mg / ml, and the glutamic acid content was 6.005 mg / ml. From this, it can be inferred that the obtained crystal was zinc glutamate and hydrochlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com