Advanced waste water treatment method

A wastewater treatment and wastewater technology, which is applied in the fields of water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. Long time and other problems, to achieve the effect of reducing the amount of production and improving the oxidation rate of Fenton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, processing pharmaceutical waste water

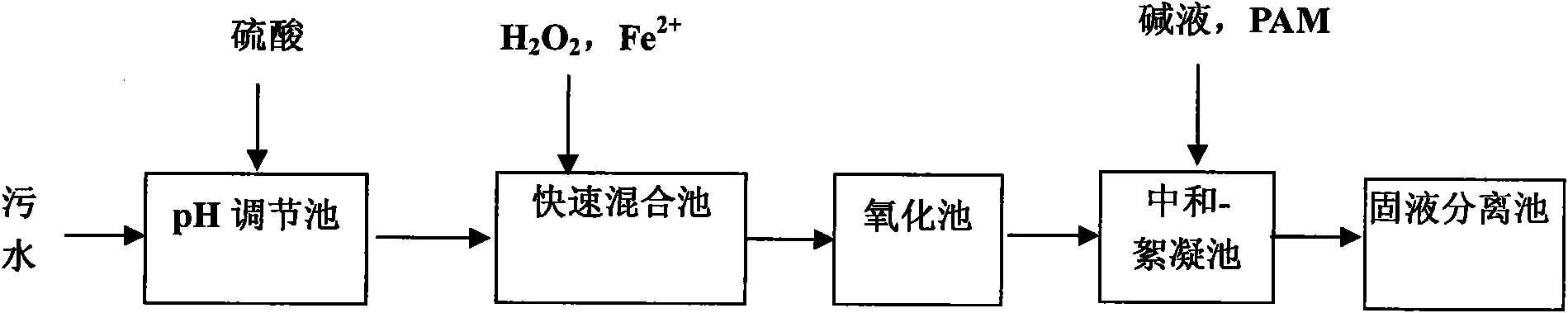

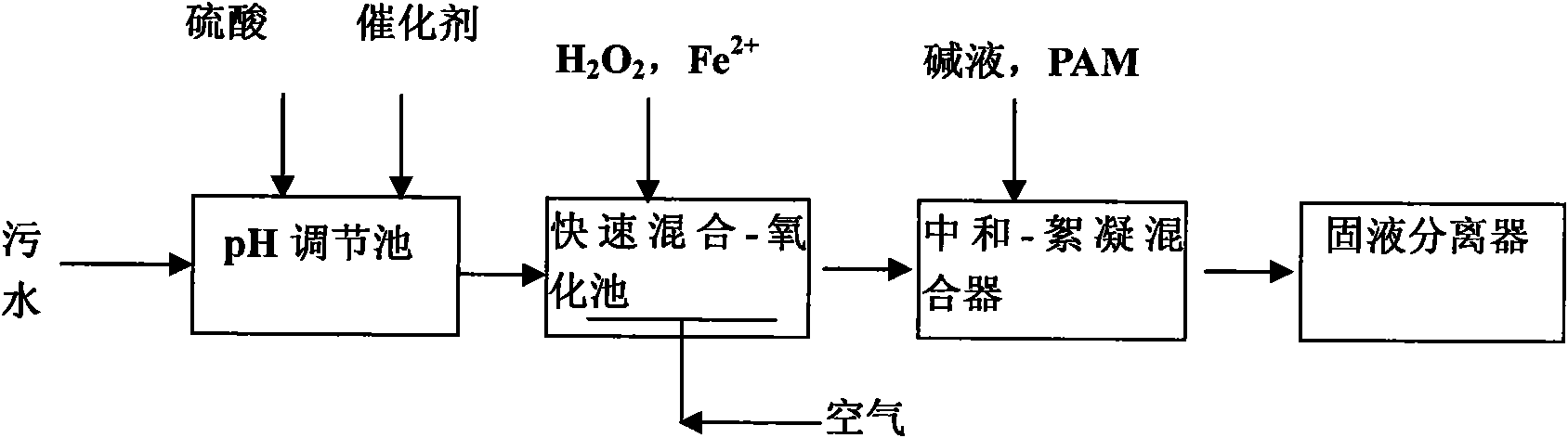

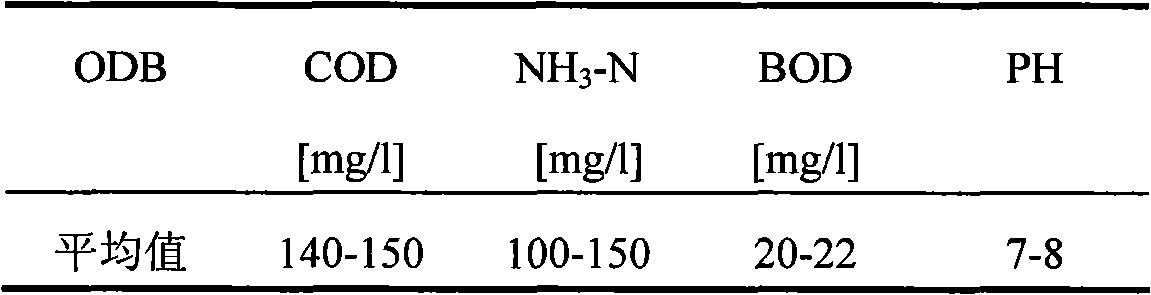

[0020] The sewage from a pharmaceutical industrial park in China was taken for testing. The quality of raw water is shown in Table 1. From Table 1, it can be seen that this sewage has the characteristics of low COD (chemical oxygen demand), medium concentration of ammonia nitrogen and poor biochemical properties. use figure 2 The process flow shown is to treat the pharmaceutical wastewater. First, adjust the alkalinity of the sewage to less than 10mg / L in terms of calcium carbonate, add 5mg of anthraquinone per liter of sewage, enter the Fenton (mixed solution of hydrogen peroxide and ferrous iron) reaction tank, and stir under air Add hydrogen peroxide and ferrous sulfate, the amount of hydrogen peroxide added is 0.5 times (50-60mg / L) of the concentration of influent COD, the amount of ferrous sulfate added is 10.0 mg / L in terms of ferrous ions, and the air stirring The gas-water ratio is 5:1 (volume ratio). Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com