A mcraly coating with excellent oxidation resistance and preparation method thereof

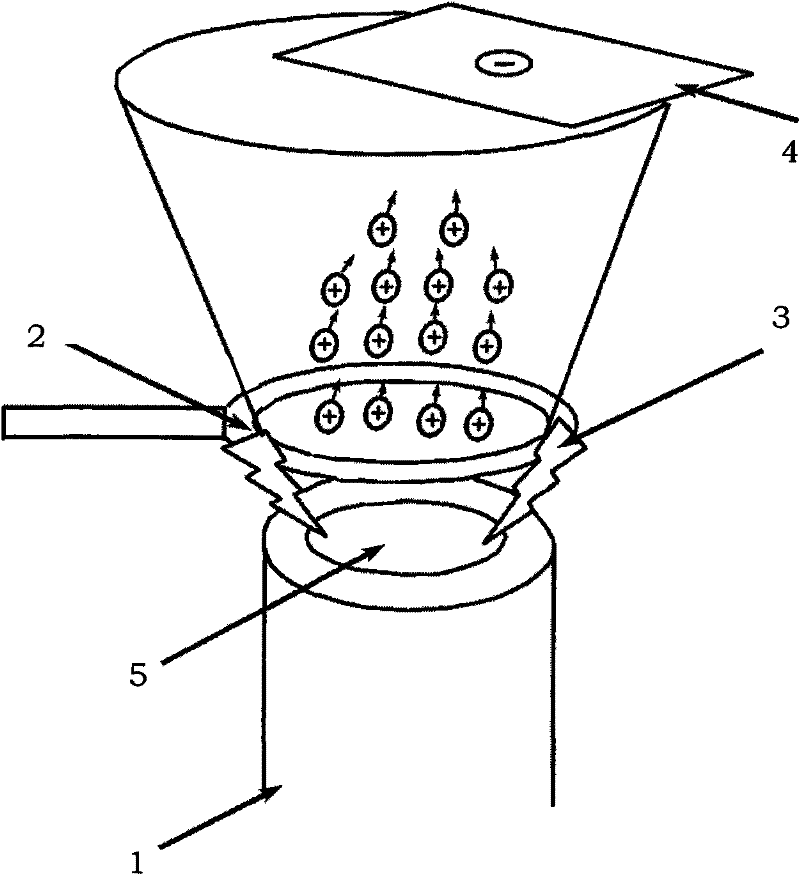

A coating and equipment technology, applied in the field of preparing MCrAlY coating by ion-assisted electron beam physical vapor deposition technology, can solve the problems of high cost, high coating deposition efficiency, large porosity, etc., and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

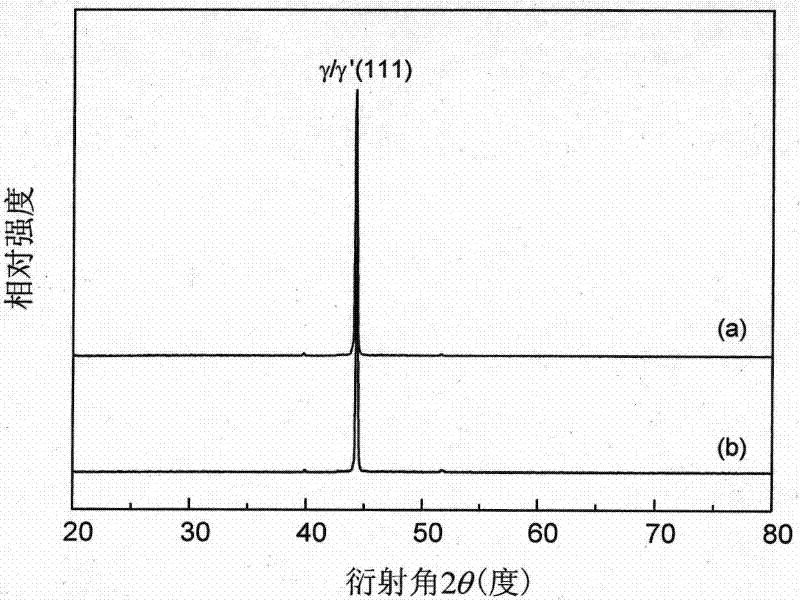

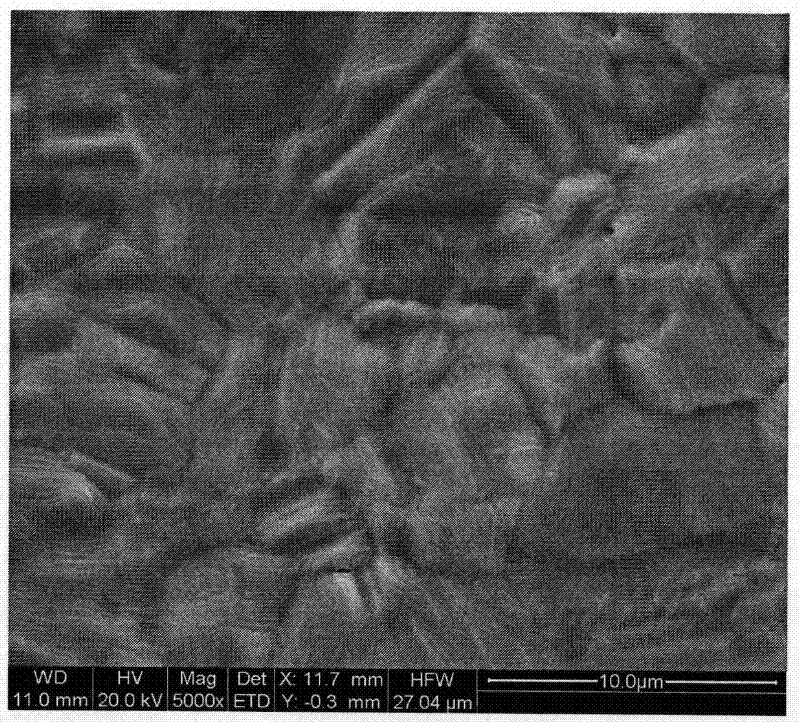

[0045] Embodiment 1: NiCoCrAlY coating is prepared on the as-cast NiCoCrAlY alloy substrate

[0046] (1) prepare the evaporating material rod, and set it aside;

[0047] The composition of NiCoCrAlY rod is nickel, cobalt, chromium, aluminum and yttrium, and its percentage by weight is 47.8% nickel, 20% cobalt, 22% chromium, 8.8% aluminum, 1.4% yttrium, the total amount of the above-mentioned components is 100%;

[0048] (2) Polish the Φ16×2mm disc cut from the above-mentioned rod with 150#, 300#, 400#, 800# sandpaper sequentially to make the surface roughness Ra<0.8. Then put it into acetone for ultrasonic cleaning for 30min, and install it on the rotating substrate frame of electron beam physical vapor deposition equipment;

[0049] (3) NiCoCrAlY feed rod is placed in the water-cooled copper crucible;

[0050] (4) Pump the vacuum chamber to the required lower than 5×10 -3 Pa vacuum degree;

[0051] (5) Set the rotational speed of the rotating substrate holder to 12rpm, a...

Embodiment 2

[0059] Embodiment 2: CoCrAlY coating is prepared on the DZ125 alloy substrate

[0060] (1) Prepare the evaporating material stick, spare

[0061] The composition of CoCrAlY feed rod is cobalt, chromium, aluminum and yttrium, and its percentage by weight is 57% cobalt, 30% chromium, 12% aluminum, 1.0% yttrium, and the total amount of above-mentioned each composition is 100%;

[0062] (2) Wire-cut the Φ16 DZ125 (composition in Table 1) alloy test rod into 2mm discs and polish it with 150#, 300#, 400#, 800# sandpaper in sequence to make the surface roughness Ra<0.8. Then put it into acetone for ultrasonic cleaning for 30min, and install it on the rotating substrate frame of electron beam physical vapor deposition equipment;

[0063] Table 1 Chemical composition of DZ125 alloy (wt.%)

[0064]

[0065] (3) CoCrAlY feed rod is placed in the water-cooled copper crucible;

[0066] (4) Pump the vacuum chamber to the required lower than 5×10 -3 Pa vacuum degree;

[0067] (5) Set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com