Porous ultra-low dielectric constant material film and preparation method thereof

A low dielectric constant, material thin film technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problem of not meeting the requirements of k value, and achieve ultra-low dielectric constant, good controllability, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

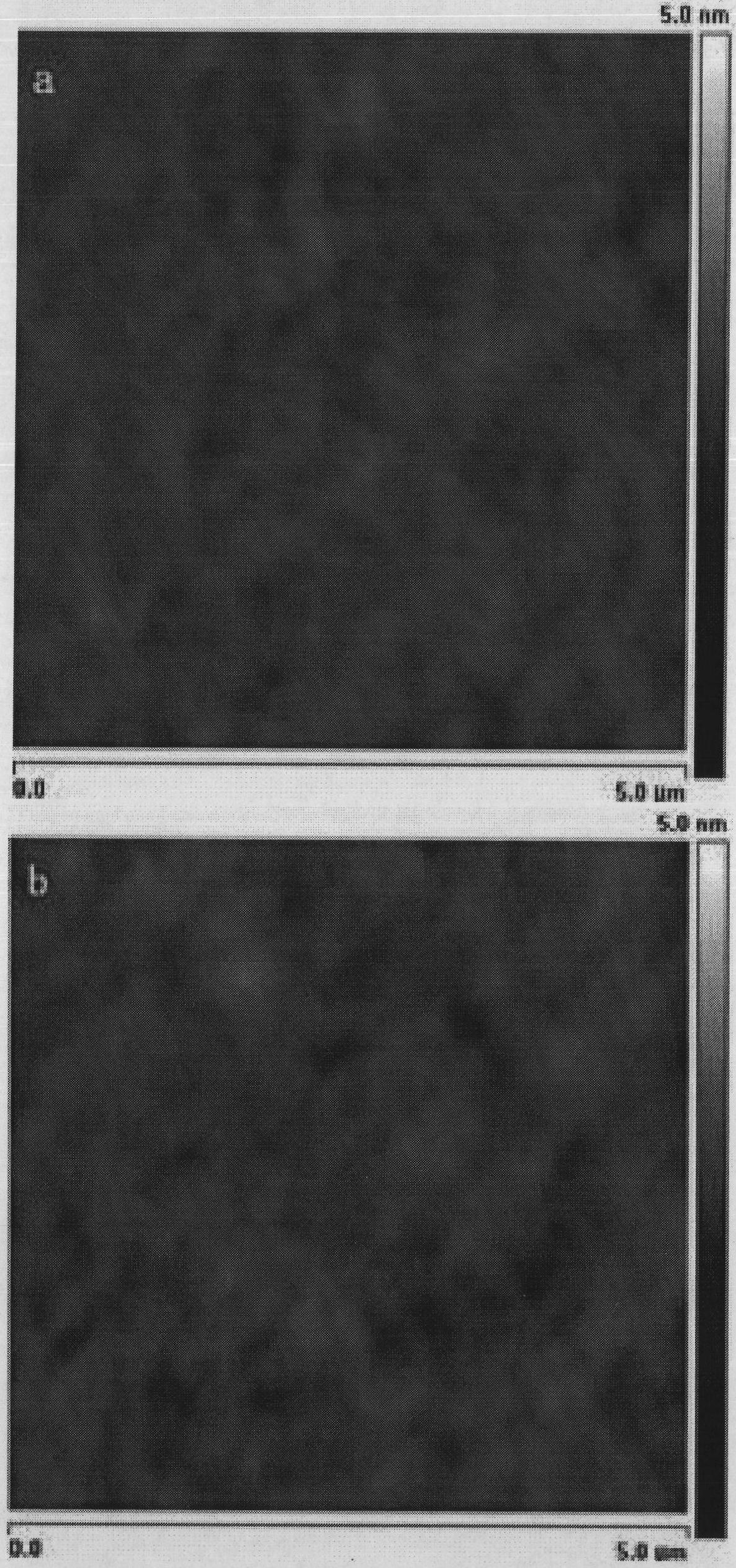

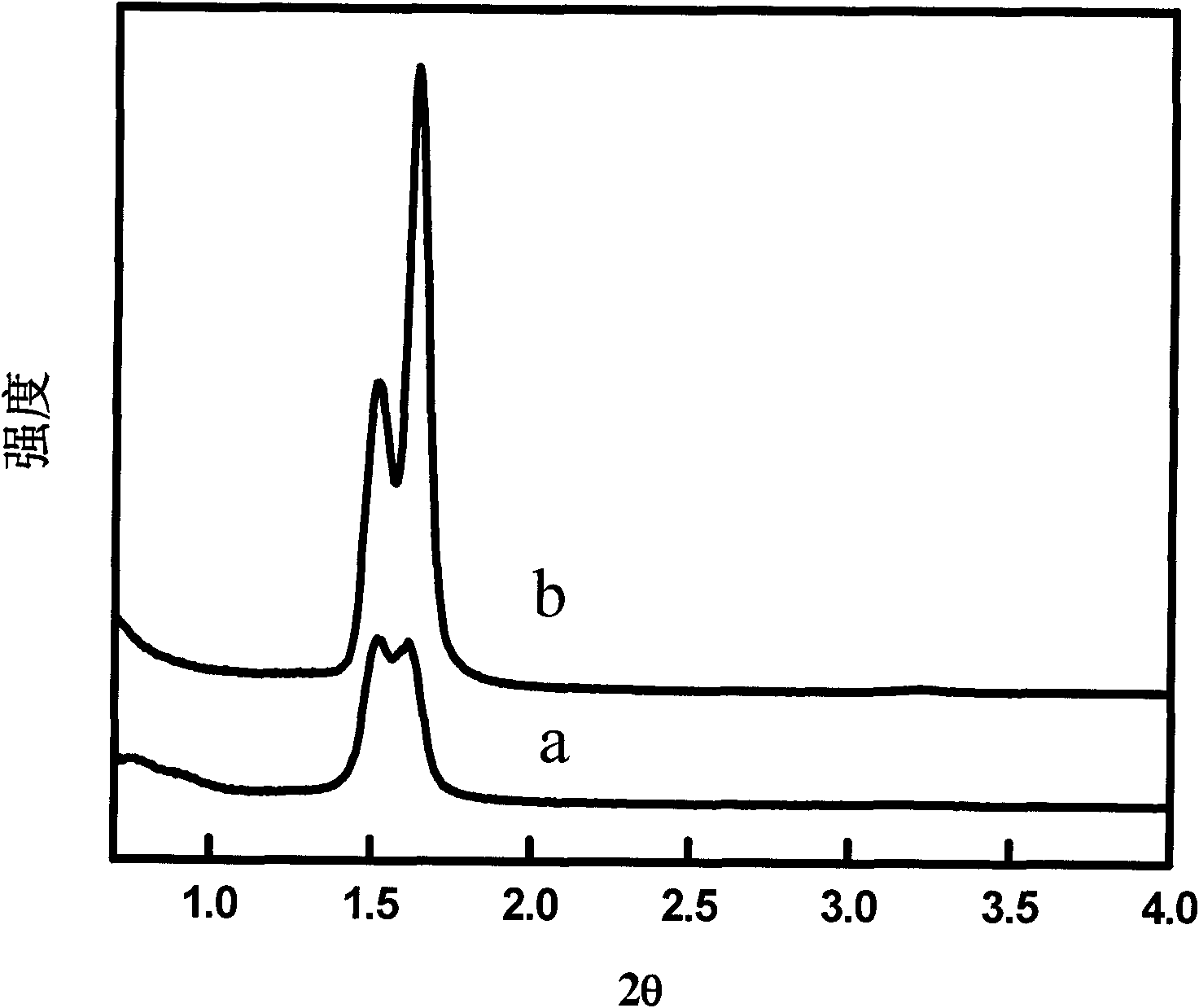

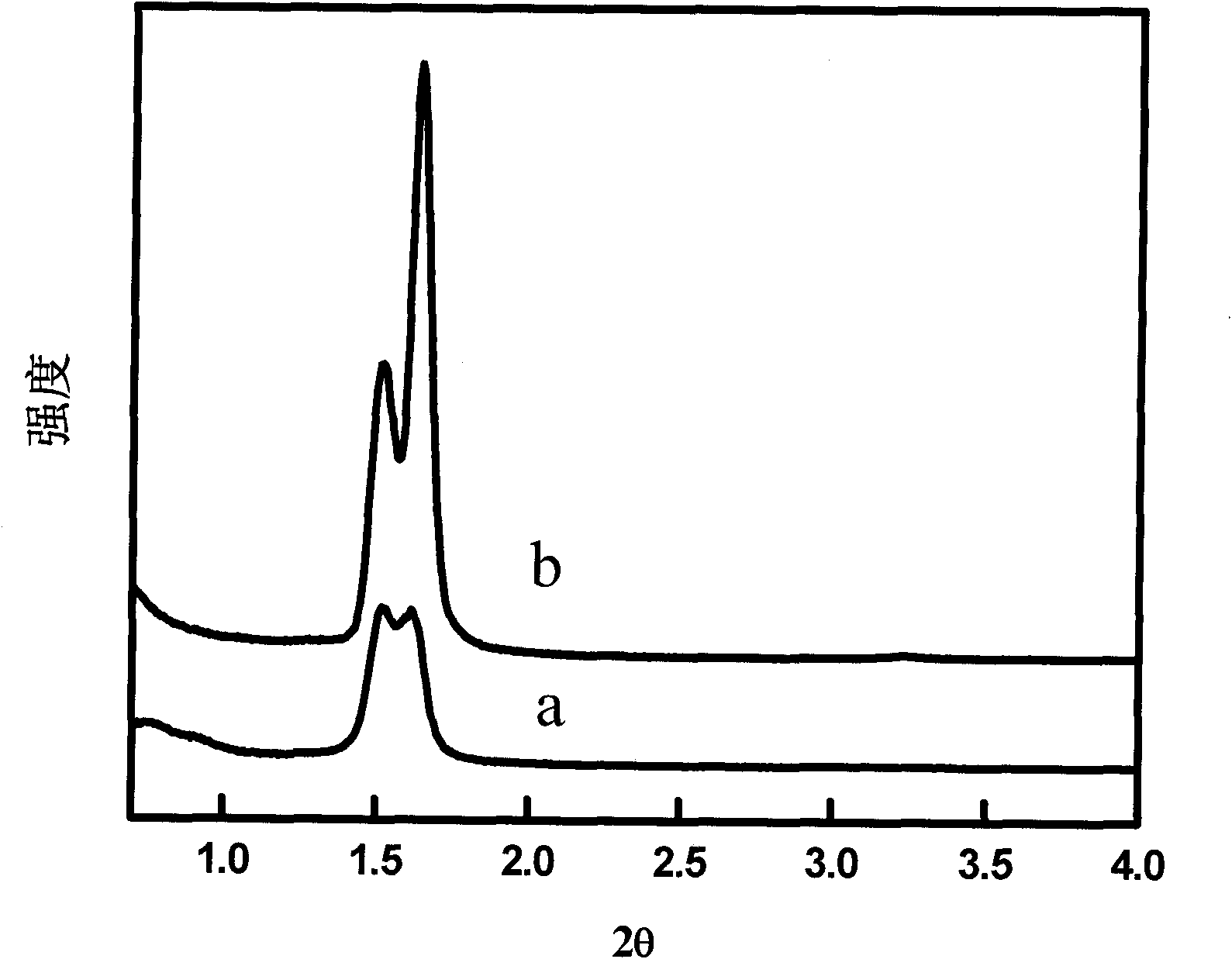

Image

Examples

Embodiment 1

[0023] 1. Add CH 3 Si(OEt) 3 and (EtO) 3 Si-CH 2 -CH 2 -Si(OEt) 3 Mix and stir until well blended, P 123 , the mixture of hydrochloric acid, ethanol and water was stirred evenly, then added to the mixture of the precursor, and stirred in a water bath at 60° C. for 2 hours. The molar ratio of the above components in sample I is: CH 3 Si(OEt):(EtO) 3 Si-CH 2 -CH 2 -Si(OEt) 3 :P 123 :HCl:H 2 O:EtOH=0.25:0.375:1.23×10 -2 : 1.80×10 -2 :20:13.9. The molar ratio of the above components in sample II is: CH 3 Si(OEt):(EtO) 3 Si-CH 2 -CH 2 -Si(OEt) 3 :P123:HCl:H 2 O:EtOH=0.25:0.375:1.23×10 -2 : 1.80×10 -2 :20:14.37.

[0024] 2. Spin-coat the above-mentioned film-forming solution on a clean silicon wafer as a substrate at 25°C to form a film. The spin-coating step is as follows: first, spin at 800 rpm for 10 seconds, and then accelerate to 2000 rpm for 20 seconds. Let stand for 30-60 minutes before use.

[0025] 3. Place the above-mentioned films I and II in an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com