Technology for recycling wastewater resulted from production of aromatic polycarboxylic acid

A technology for the production of aromatic carboxylic acid and waste water, which is applied in water/sewage multi-stage treatment, light water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of petrochemical waste water treatment that have not been reported, and achieve cost The effect of low cost, reduced equipment and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

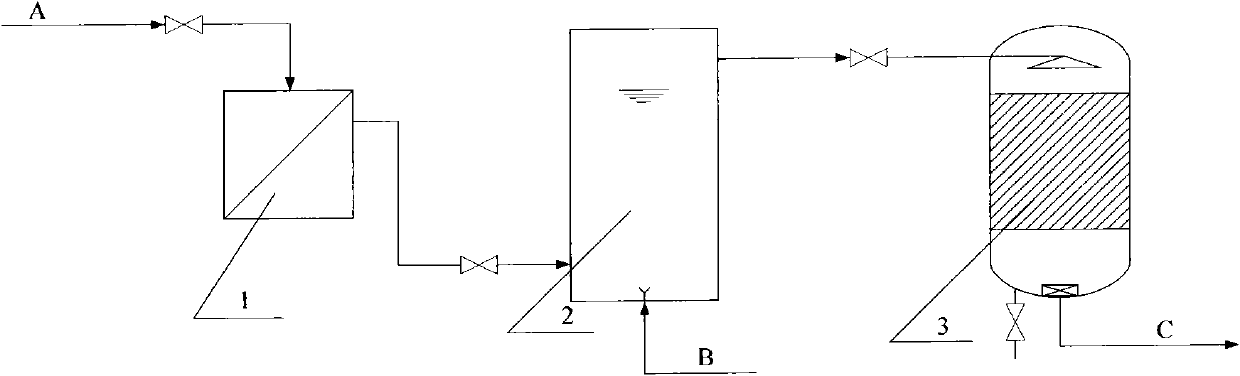

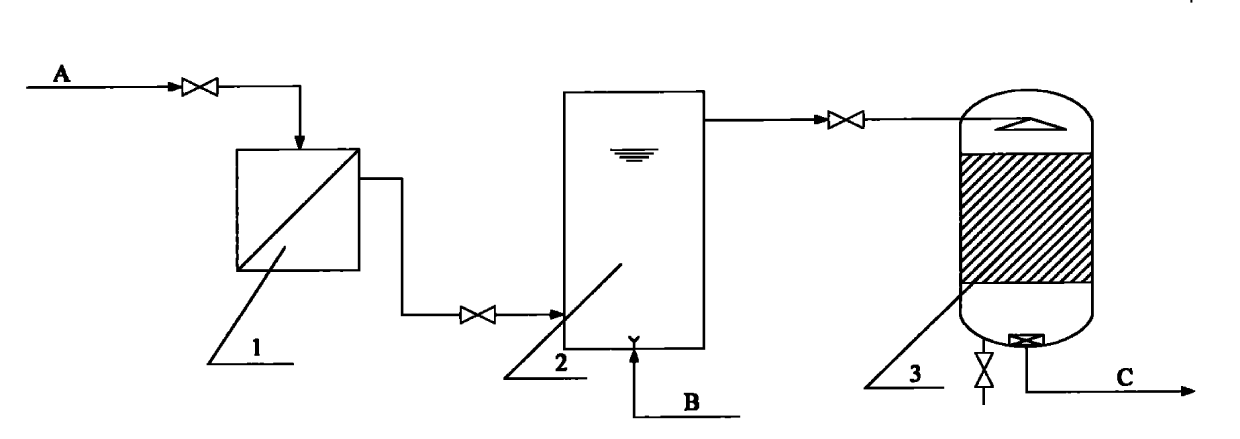

Image

Examples

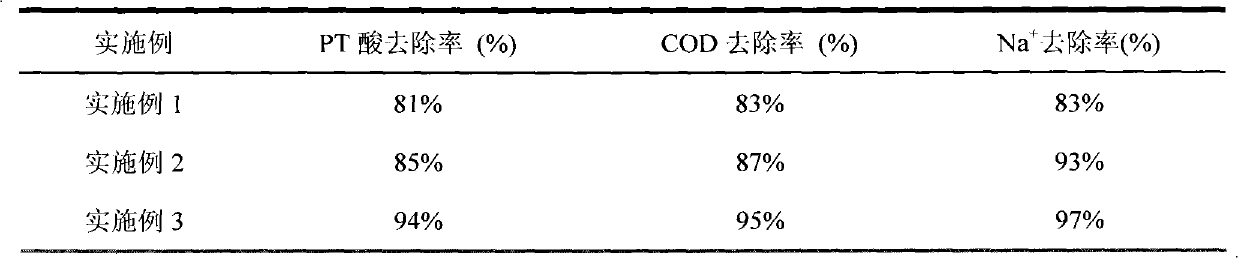

Embodiment 1

[0034] The waste water enters the T-type filter filter, the filtrate enters the fixed bed photocatalytic reactor, and 400kgTiO is added 2 The photocatalyst is placed in a photocatalytic reactor, the light source power is 50W, and the reaction temperature is 30°C. The wastewater stays in the photocatalytic reactor for 1 hour, and the effluent from the reactor enters the ion exchange column. The resin uses a strongly acidic styrene-based cation exchange resin, and the residence time of the wastewater in the ion exchange column is 0.5 hour. After the whole system was running for 4 hours, samples were taken to analyze the PT acid content, metal ion content, and COD value in the water, and the removal rate of each index was calculated. The results are shown in Table 1.

Embodiment 2

[0036] The waste water enters the duplex switching filter, the filtrate enters the fluidized bed photocatalytic reactor, and 1000kg Fe-TiO is added 2 / AC photocatalyst in a photocatalytic reactor, the light source power is 100W, and the reaction temperature is 50°C. The wastewater stays in the photocatalytic reactor for 2 hours, and the effluent from the reactor enters the ion exchange column. The resin uses a super-porous bispolystyrene cationic resin, and the residence time of the wastewater in the ion exchange column is 1 hour. After the whole system was running for 4 hours, samples were taken to analyze the PT acid content, metal ion content, and COD value in the water, and the removal rate of each index was calculated. The results are shown in Table 1.

Embodiment 3

[0038] 10%Fe-TiO 2 / 1.4% NH 4 + -AC(TiO 2 The loading quality is 18%) preparation steps:

[0039] (1) preparation molar concentration is 1L of ethanol aqueous solution of 3mol / L, under stirring, add 57g ferric sulfate and 20g ammonium nitrate, form solution A after mixing;

[0040] (2) Prepare 1 L of a mixed solution of n-butyl titanate and ethanol with a molar concentration of 2 mol / L, and add 0.4 g of hydroxypropyl cellulose to form a solution B;

[0041] (3) Add 500g gac to A solution, after stirring evenly, form solution A1, the solution B in the step (2) is separated by 400cm 3 The speed of / h is added dropwise in the A1 solution;

[0042](4) preparation molar concentration is 1L of aqueous ethanol solution of 3mol / L, under stirring, add 57g ferric sulfate and 20g ammonium nitrate, form solution A after mixing;

[0043] (5) Prepare 1 L of a mixed solution of n-butyl titanate and ethanol with a molar concentration of 2 mol / L, and add 0.4 g of hydroxypropyl cellulose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com