Method for synthesizing 1-substituted-1,2,3-tolyltriazole

A synthetic method, triazole technology, applied in the field of organic and pharmaceutical synthesis, can solve problems such as no effective synthetic route, and achieve the effect of high yield, easy industrialization, novel and effective synthetic method

- Summary

- Abstract

- Description

- Claims

- Application Information

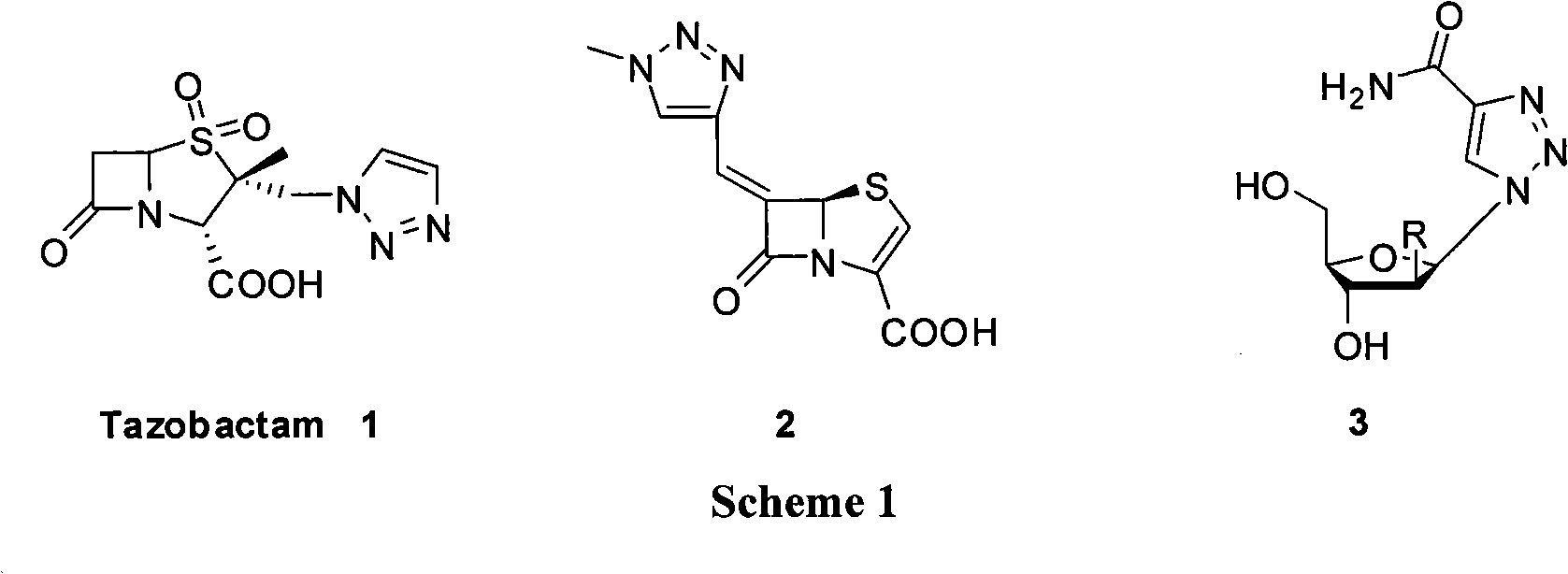

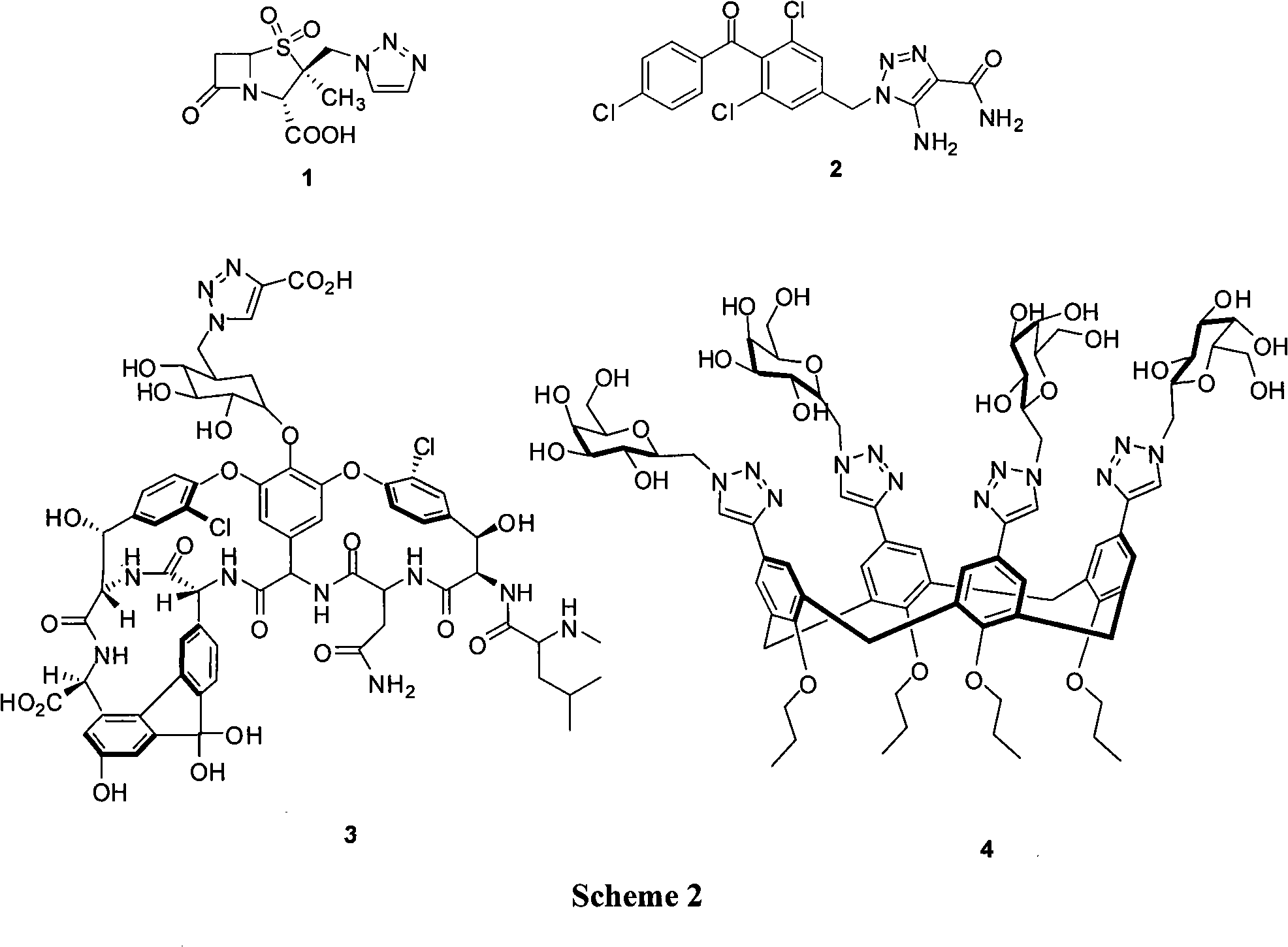

AI Technical Summary

Problems solved by technology

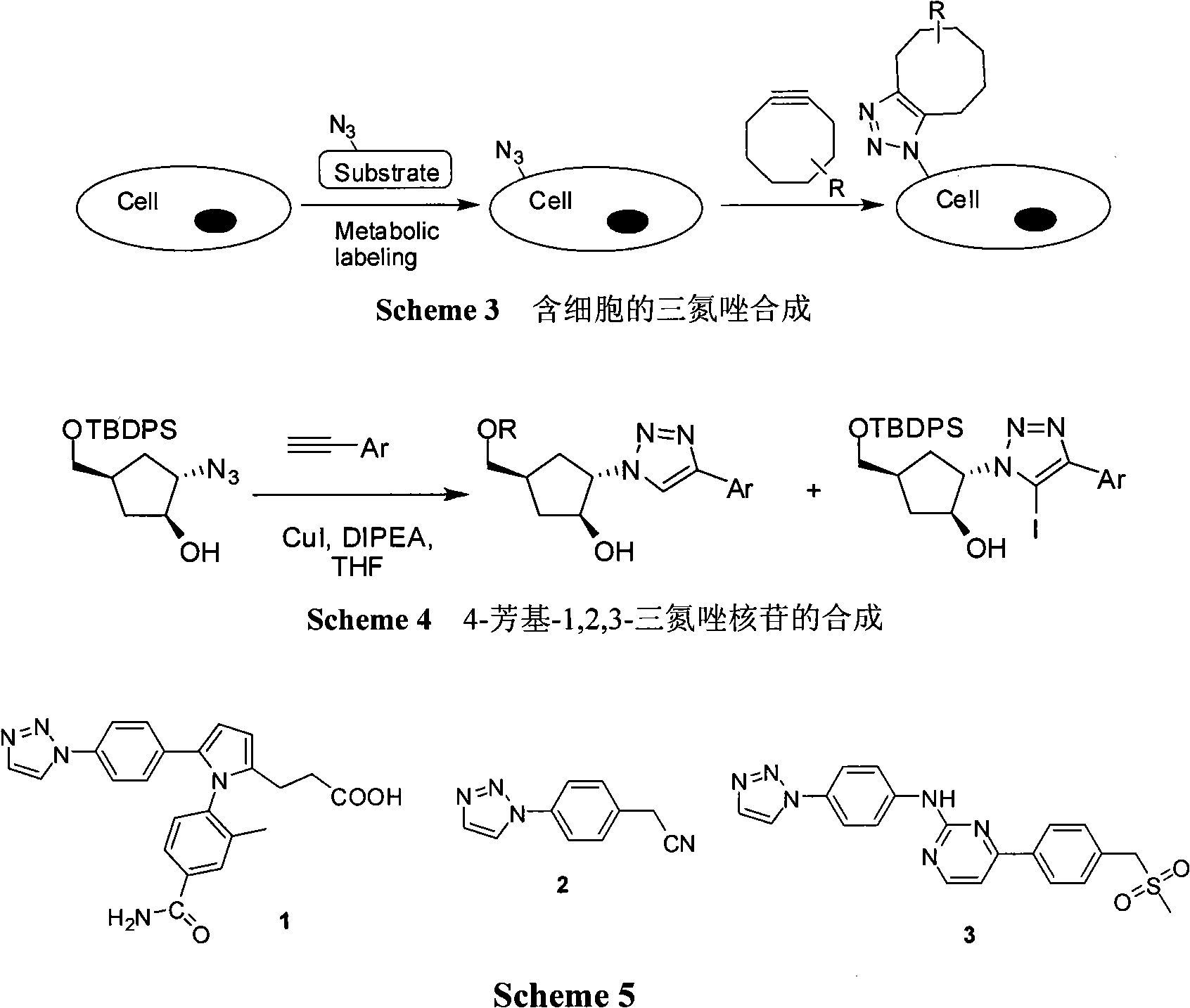

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the synthesis of 1-p-tolyl-1,2,3-triazole

[0022]

[0023] Add cuprous iodide (0.07mmol), sodium ascorbate (0.14mmol), p-tolyl azide (0.4mmol), propiolic acid (0.57mmol) and DMF 2mL to the reactor, and react with magnetic stirring at room temperature for 16 hours, After the reaction was completed, it was extracted with ethyl acetate, the organic layer was washed with saturated brine, dried over anhydrous sodium sulfate, and the solvent was evaporated under reduced pressure to obtain the crude product. The crude product was prepared at a volume ratio of ethyl acetate / petroleum ether=1:2 The eluent was purified by column chromatography to obtain the desired product as a light yellow solid with a yield of 87%.

[0024] Its NMR data are as follows:

[0025] 1 H NMR (500MHz, CDCl 3 ): δ = 7.95 (1H, d, J = 1.0Hz), 7.83 (1H, d, J = 1.0Hz), 7.62 (2H, q, J = 1.8Hz), 7.32 (2H, d, J = 8.0Hz ), 2.43 (3H, s).

Embodiment 2

[0026] Embodiment 2: Synthesis of 1-p-fluorophenyl-1,2,3-triazole

[0027]

[0028] Add cuprous iodide (0.07mmol), sodium ascorbate (0.14mmol), p-fluorophenyl azide (0.37mmol), propiolic acid (0.55mmol), triethylamine (0.19mmol) and DMF 2mL to the reactor , and reacted with magnetic stirring at 60 °C for 3 hours. After the reaction was completed, it was extracted with ethyl acetate, the organic layer was washed with saturated brine, dried over anhydrous sodium sulfate, and the solvent was evaporated under reduced pressure to obtain the crude product. The crude product was prepared with ethyl acetate / petroleum ether=(1:5-1 : volume ratio of 3) was the eluent and purified by column chromatography to obtain the desired product as a white solid with a yield of 90%.

[0029] Its NMR data are as follows:

[0030] 1 H NMR (500MHz, CDCl 3 ): δ = 7.95 (1H, d, J = 1.0Hz), 7.85 (1H, d, J = 1.0Hz), 7.73 (2H, q, J = 4.6Hz), 7.24 (2H, q, J = 8.1Hz ).

Embodiment 3

[0031] Example 3: Synthesis of 1-p-methoxyphenyl-1,2,3-triazole

[0032]

[0033] Add cuprous iodide (0.02mmol), sodium ascorbate (0..04mmol), p-methoxyphenyl azide (0.34mmol), propiolic acid (0.50mmol), DBU (0.17mmol) and DMF 2mL, magnetically stirred at 80°C for 5 hours. After the reaction was completed, it was extracted with ethyl acetate, the organic layer was washed with saturated brine, dried over anhydrous sodium sulfate, and the solvent was evaporated under reduced pressure to obtain the crude product. The crude product was prepared with ethyl acetate / petroleum ether=(1:5-1 : 2 volume ratio) as the eluent and purified by column chromatography to obtain the desired product as a yellow solid with a yield of 94%.

[0034] Its NMR data are as follows:

[0035] 1 H NMR (500MHz, CDCl 3 ): δ = 7.91 (1H, d, J = 0.8Hz), 7.83 (1H, d, J = 0.8Hz), 7.64 (2H, q, J = 2.2Hz), 7.03 (2H, q, J = 2.2Hz ), 3.87 (3H, s).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com