Process for growing phi 8'' solar-grade Czochralski silicon by using 18-inch thermal field

A solar-grade, Czochralski technology, applied in crystal growth, single crystal growth, self-molten liquid pulling method, etc., can solve the problems of unsmooth gas flow, unfavorable volatile discharge, high power consumption, and eliminate leakage. The phenomenon of gas and magnetic leakage, which is conducive to the removal of volatiles, and the effect of improving quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 18

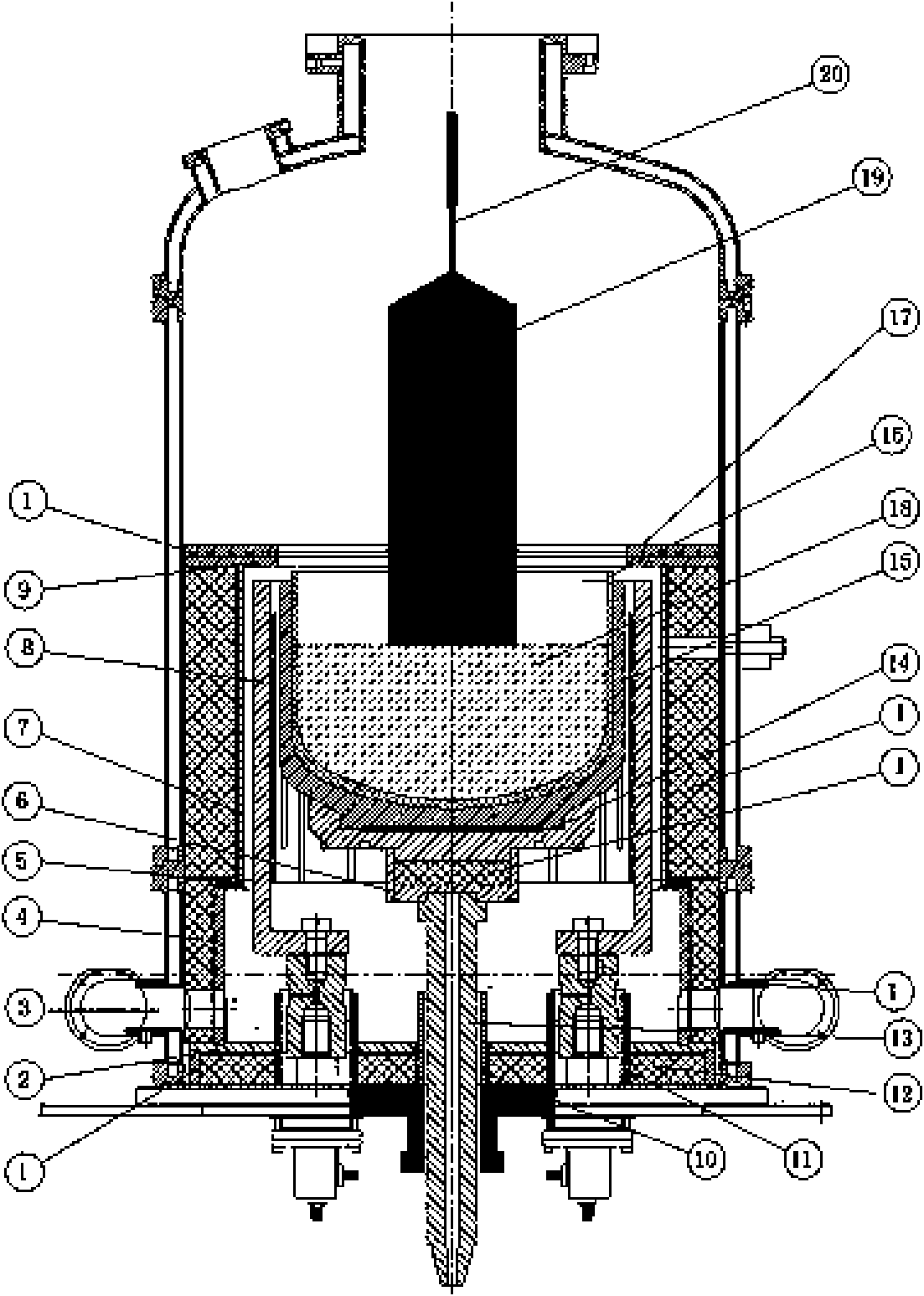

[0053] In this embodiment, the 18-inch thermal field growth Φ8″ solar-grade Czochralski silicon single crystal process adopts an 18-inch thermal shield thermal field and an upper-axis magnetic fluid sealing device with a cooling system, wherein:

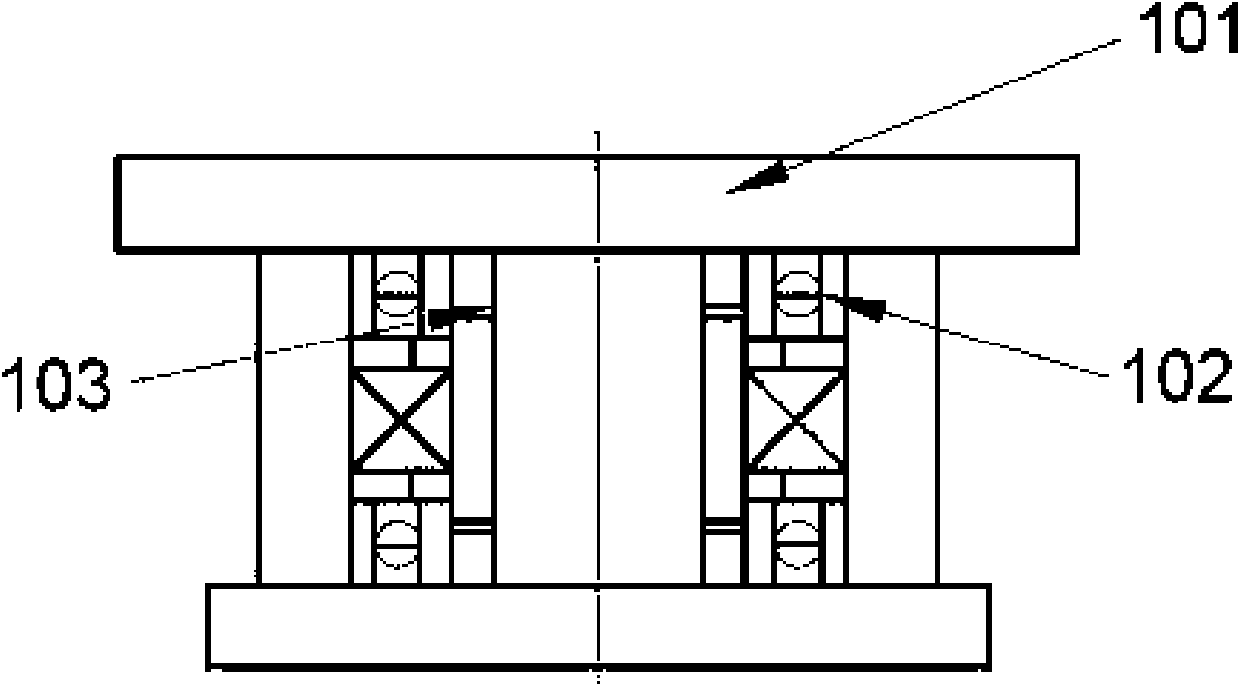

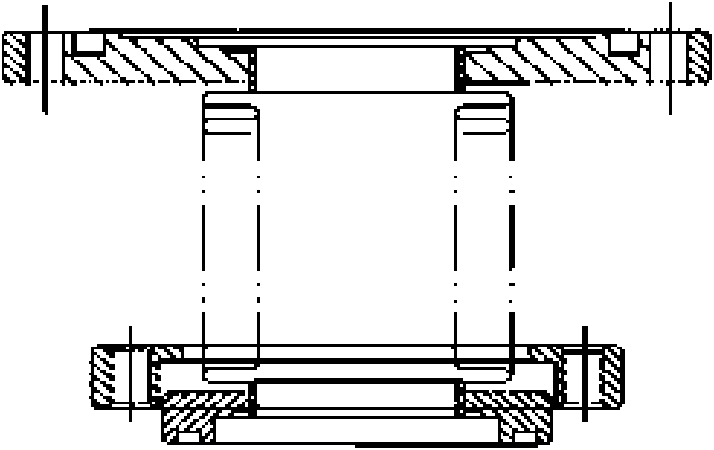

[0054] The structure of the 18-inch heat shield heat field is as follows Figure 5 ( Figure 5 is a schematic diagram with molten silicon, single crystal silicon rods, and seed crystals installed) and Image 6 As shown, it includes the same structure as the open heat field: graphite felt 1, graphite sheet 2, exhaust port 3, lower graphite insulation cylinder 4, lower graphite support ring 5, central axis extension 6, graphite insulation cylinder 7, heating Device 8, upper supporting ring 9, central shaft sheath 10, electrode sheath 11, electrode quartz sheath 12, graphite central shaft 13, crucible holder 14, graphite crucible 15, quartz crucible 16, upper heat preservation cover 17; also includes The same structure as the open hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com