Manufacturing method of film material for solar cells

A technology of solar cells and thin film materials, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of high manufacturing cost, attenuation of photoelectric conversion efficiency, and low conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

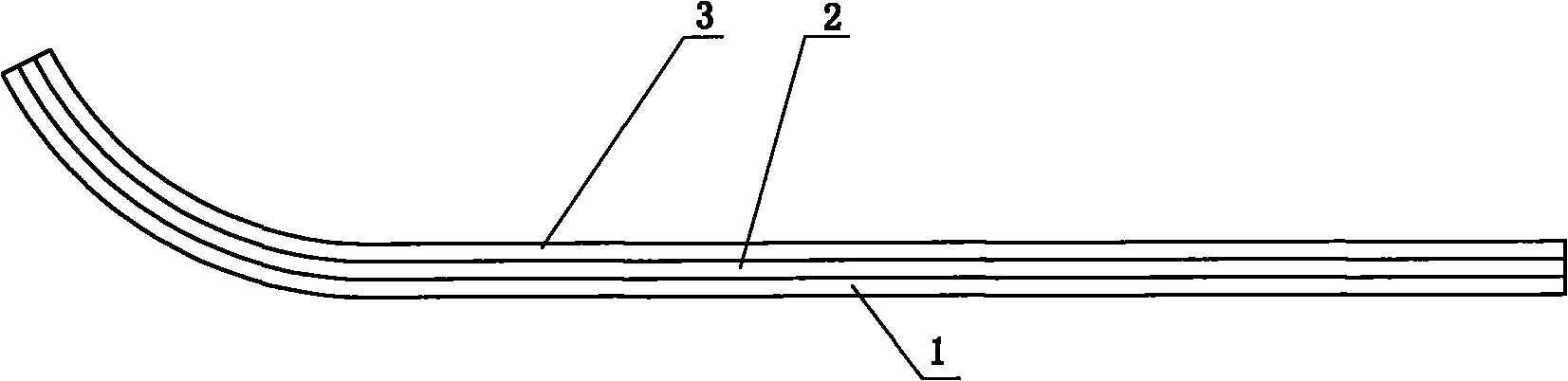

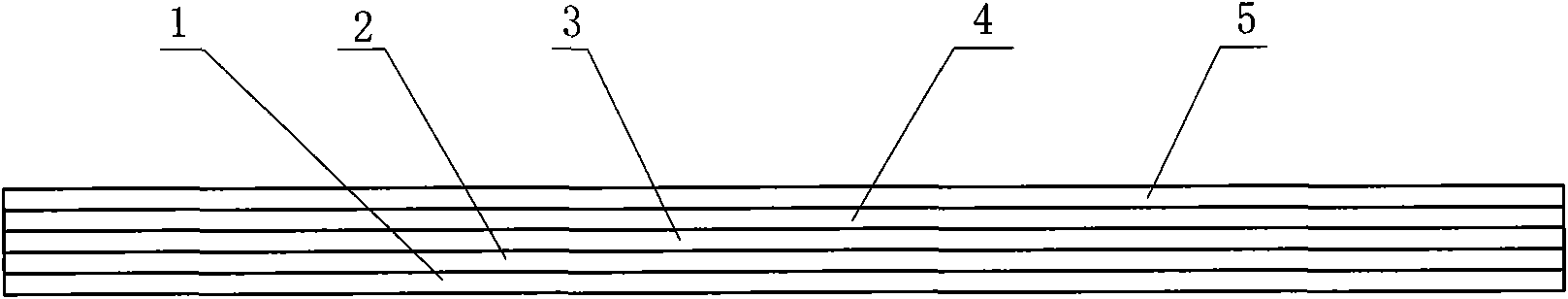

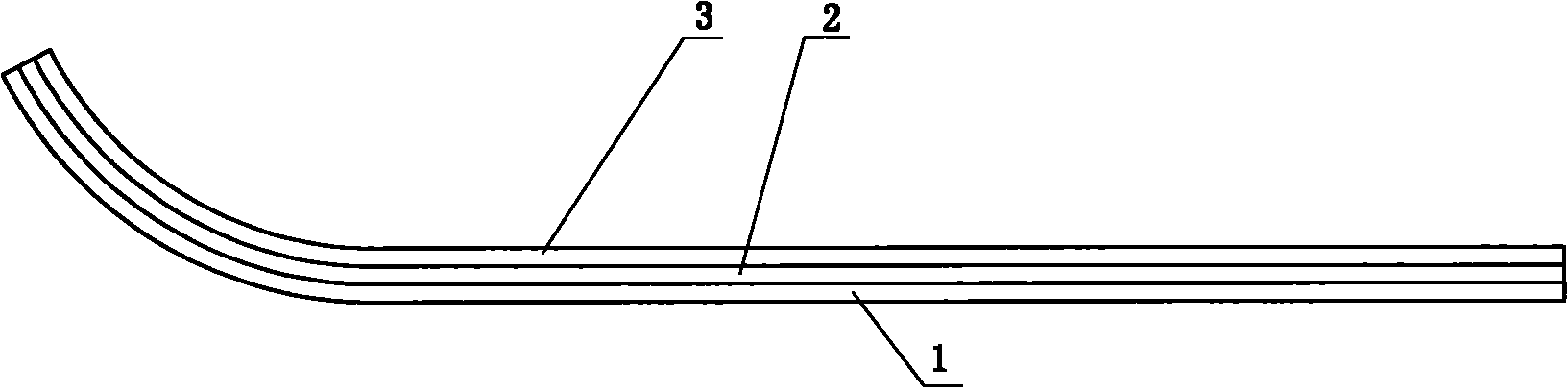

[0038] Example 1, using a 0.25 mm thick Hastelloy 276 substrate layer 1 after electrochemical polishing, using vacuum electron beam evaporation technology and inclined substrate deposition method to prepare a layer of 1 micron MgO and 1 micron yttrium oxide Y at room temperature 2 o 3 Template film layer 2, and then grow a layer of 50 nm CeO 2 , the Si semiconductor thin film layer 3 is prepared by chemical vapor deposition CVD under the condition of 600-800°C. The X-ray rocking curve FWHM used to evaluate the texture degree of the film along the plane of the film is only 7°, and the texture degree is very good.

example 2

[0039] Example 2, using the 1.00 mm thick Hastelloy 276 substrate layer 1 after electrochemical polishing, using vacuum electron beam evaporation technology and inclined substrate deposition method to prepare a layer of 1 micron MgO and 1 micron yttrium oxide Y at room temperature 2 o 3 Template film layer 2, and then grow a layer of 50 nm CeO 2 , the gallium arsenide GaAs semiconductor thin film layer 3 is prepared by chemical vapor deposition CVD under the condition of 700-900° C., and the FWHM is 9°.

example 3

[0040] Example 3, the 0.8 mm thick stainless steel sheet substrate layer 1 after mechanical polishing was polished, and a layer of 1 micron MgO and 1 micron yttrium oxide Y were prepared at room temperature using vacuum electron beam evaporation technology and inclined substrate deposition method. 2 o 3 Template film layer 2, and then grow a layer of 50 nm CeO 2 , and finally the GaAs semiconductor thin film layer 3 is epitaxially grown by pulsed laser deposition at 700-800° C. under vacuum, with a FWHM of 9°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com