Capacitor composed by utilizing semiconductor PN junction capacitance and manufacturing method thereof

A fabrication method and semiconductor technology are applied in the field of capacitors to achieve the effects of simple structure, small parasitic parameters and high capacitance density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

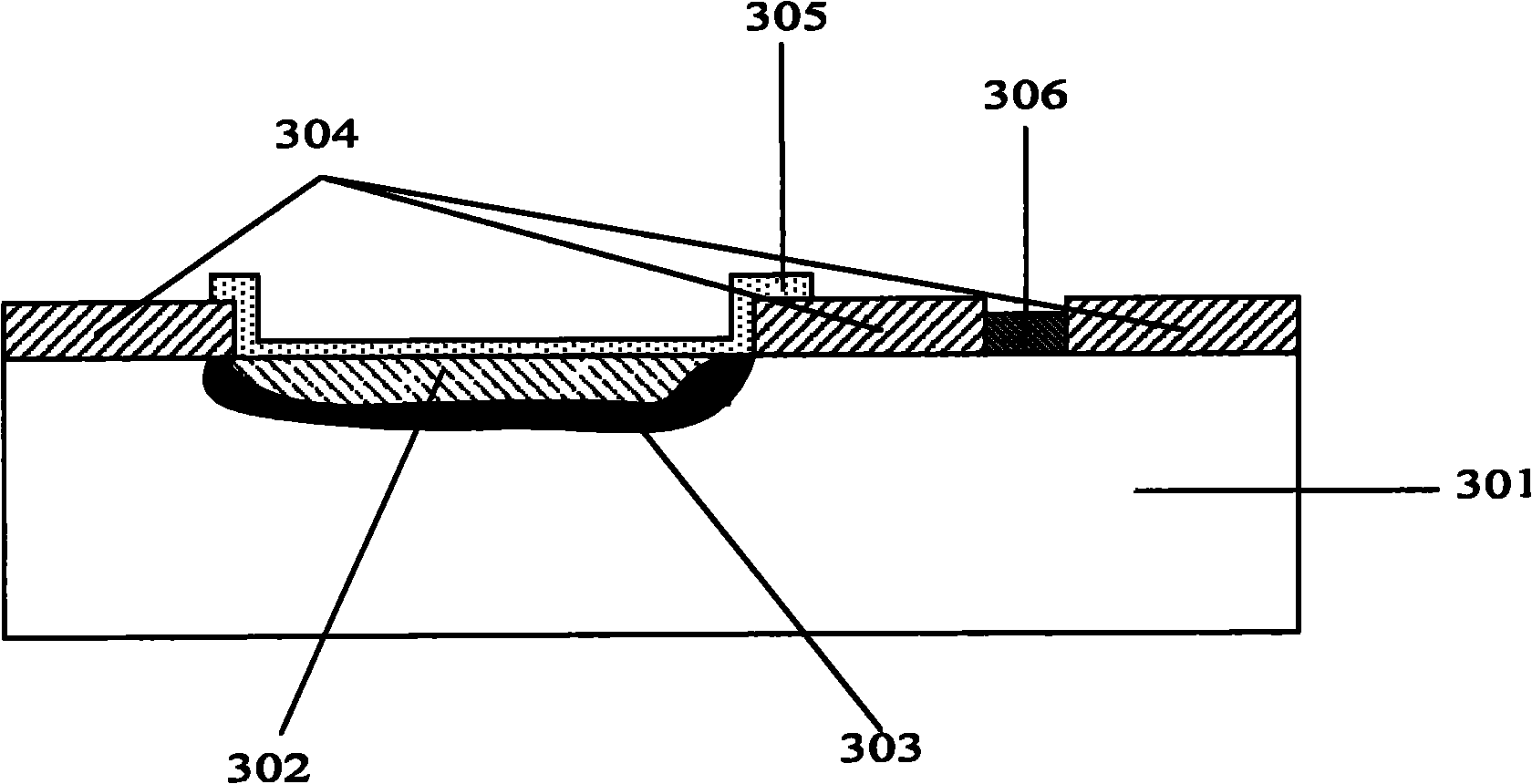

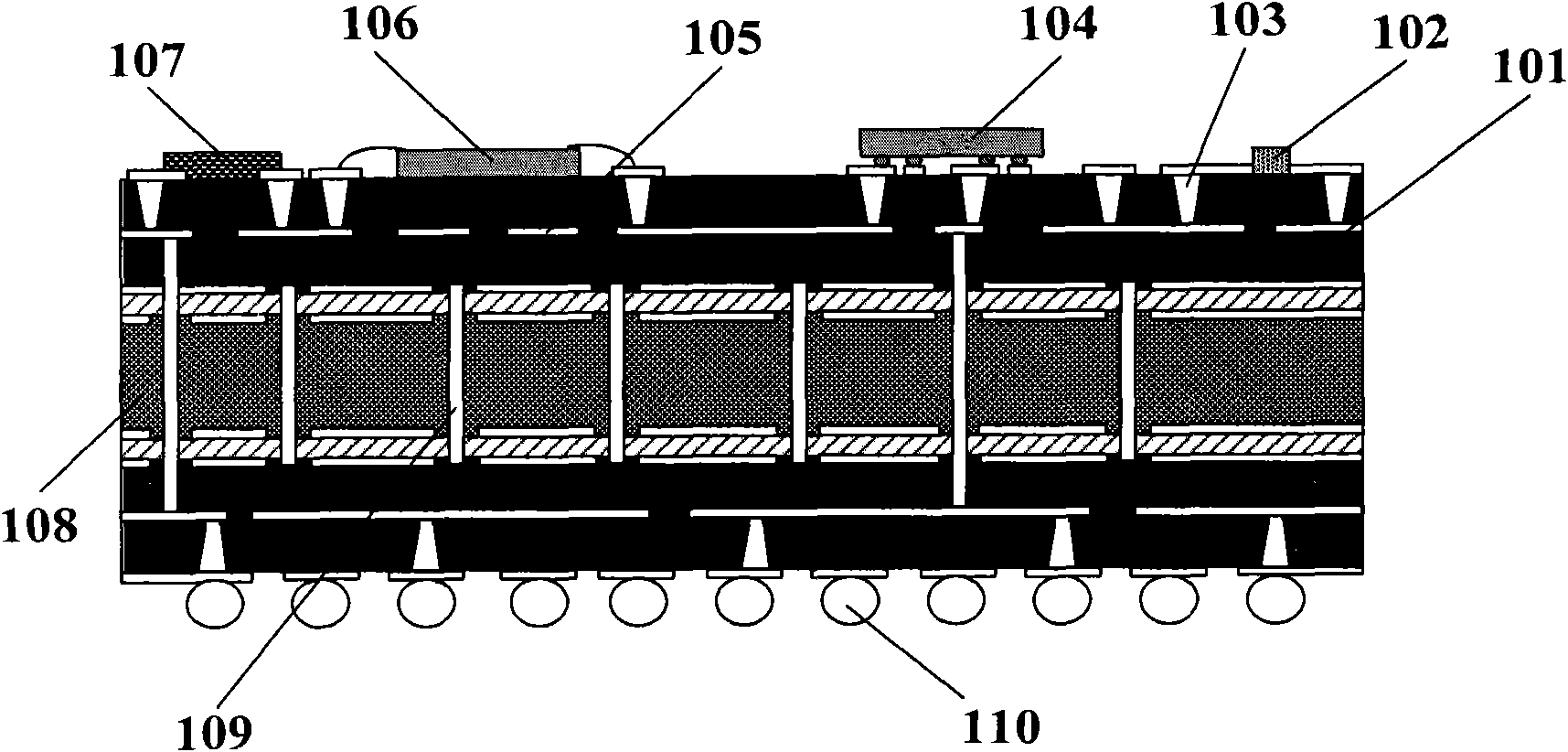

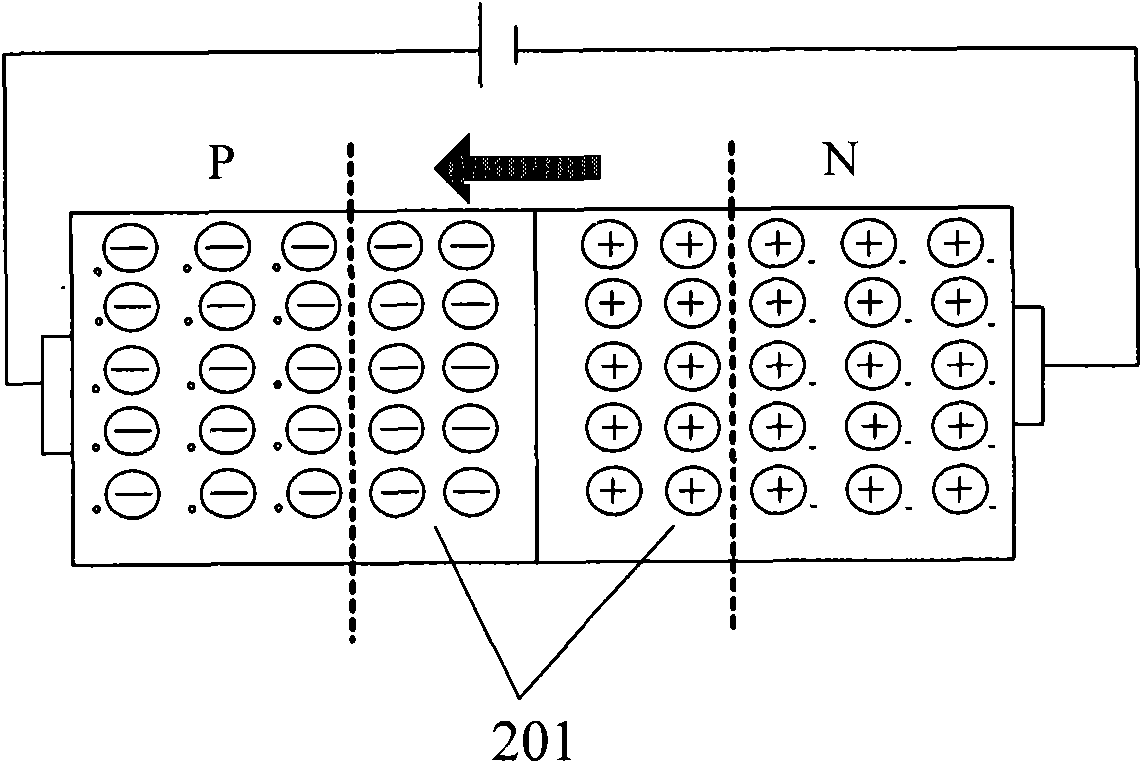

[0069] The invention uses semiconductor PN junction capacitance to replace traditional MIM "sandwich" structure capacitance, utilizes its characteristics of good high-frequency characteristics and small reverse leakage current, and is applied to decoupling circuits. The PN junction capacitance of a semiconductor includes two parts, the barrier capacitance and the diffusion capacitance. The barrier capacitance is due to the change of the applied voltage on the PN junction, which causes the "storage" and "extraction" of electrons and holes in the barrier region. , resulting in the amount of space charge in the barrier region changing with the applied voltage, which is equivalent to the charging and discharging effect of a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com