Preparation method of multi-stage nanopore electrode material of lithium ion battery

A lithium-ion battery, nano-channel technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of small reactive area, poor lithium ion and electron transport ability, etc., and achieve regular distribution and orderly degree. High, uniform aperture size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

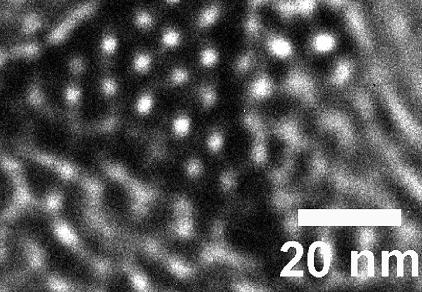

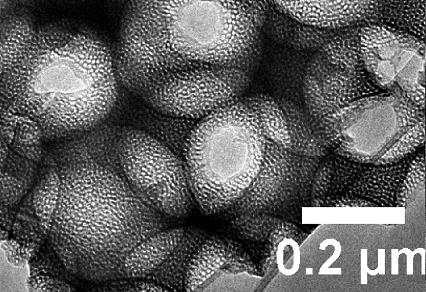

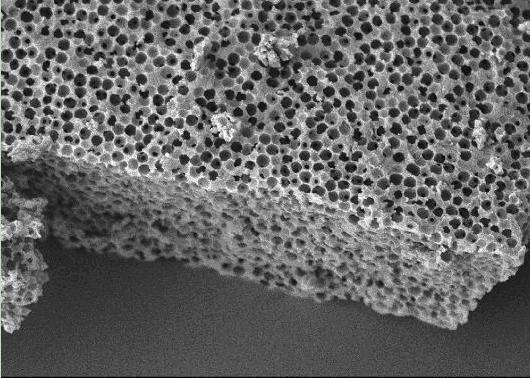

[0014] The lithium-ion battery multi-level nanoporous electrode material obtained in this embodiment is ordered mesoporous TiO 2 The thin film material is analyzed by a specific surface analyzer (produced by Micromeritics Instrument Company of the United States, model: ASAP2020), and the obtained ordered mesoporous TiO 2 The pore size in the thin film material is 2-8nm, the pore size is uniform, and the order degree is high.

[0015] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the ionic liquid described in step one is ionic liquid C16mimBr, ionic liquid EMIMBF4, ionic liquid BMIMCl, ionic liquid C16mimCl or ionic liquid BMIMPF 6 . Others are the same as the first embodiment.

specific Embodiment approach 2

[0016] Specific embodiment three: the preparation method of lithium-ion battery multilevel nanopore electrode material in the present embodiment is as follows: 1, 3.4g ionic liquid C16mimBr or 3.75g ionic liquid EMIMBF4 are dissolved in 20ml ethanol, add 4ml titanium tetrachloride, Then stir for 3 hours to obtain the mixture; 2. Cultivate the mixture in a constant temperature and humidity box with a temperature of 40°C and a humidity of 50% for 48 hours, and then dry it at 120°C for 24 hours until the mixture solidifies, and then transfer the solidified mixture In a box furnace, the temperature is raised to 350° C. at a rate of 1° C. per minute, and calcined at 350° C. for 4 hours to obtain a lithium-ion battery multi-level nanoporous electrode material.

specific Embodiment approach 3

[0017] The lithium-ion battery multi-level nanoporous electrode material obtained in this embodiment is ordered mesoporous TiO 2 The thin film material is analyzed by a specific surface analyzer (produced by Micromeritics Instrument Company of the United States, model: ASAP2020), and the obtained ordered mesoporous TiO 2 The pore size in the thin film material is about 2.3nm, the pore size is uniform, and the order degree is high.

[0018]Specific embodiment four: the preparation method of lithium-ion battery multi-level nanoporous electrode material in this embodiment is as follows: 1. Dissolve 3ml~4ml tetraisopropoxide titanium oxide in 15ml isopropanol, then add 2ml~4ml HCl solution, Stir for 1h to obtain a clear solution; 2. Dissolve the block copolymer in isopropanol, then add it to the clear solution and stir for 3h to obtain a mixture. The molar ratio of titanium isopropoxide to the block copolymer in the mixture is 1 ~1.3:0.02~0.025, the molar ratio of block copolymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com