Method for preparing butterfly lepidoptera-simulated hierarchical multi-layer symmetrical micro/nano structure

A micro-nano structure, asymmetric technology, applied in the direction of nano-structure manufacturing, micro-structure technology, micro-structure devices, etc., can solve the problems of expensive equipment, slow processing speed, unsuitable for mass production, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

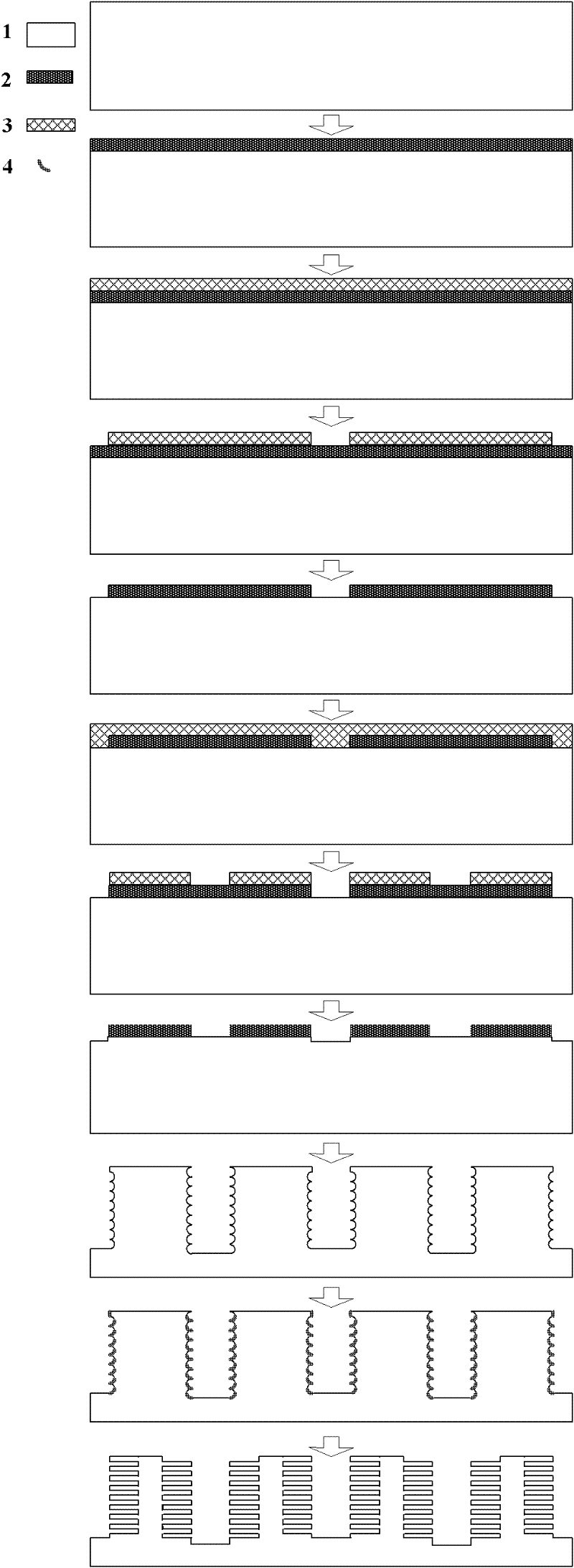

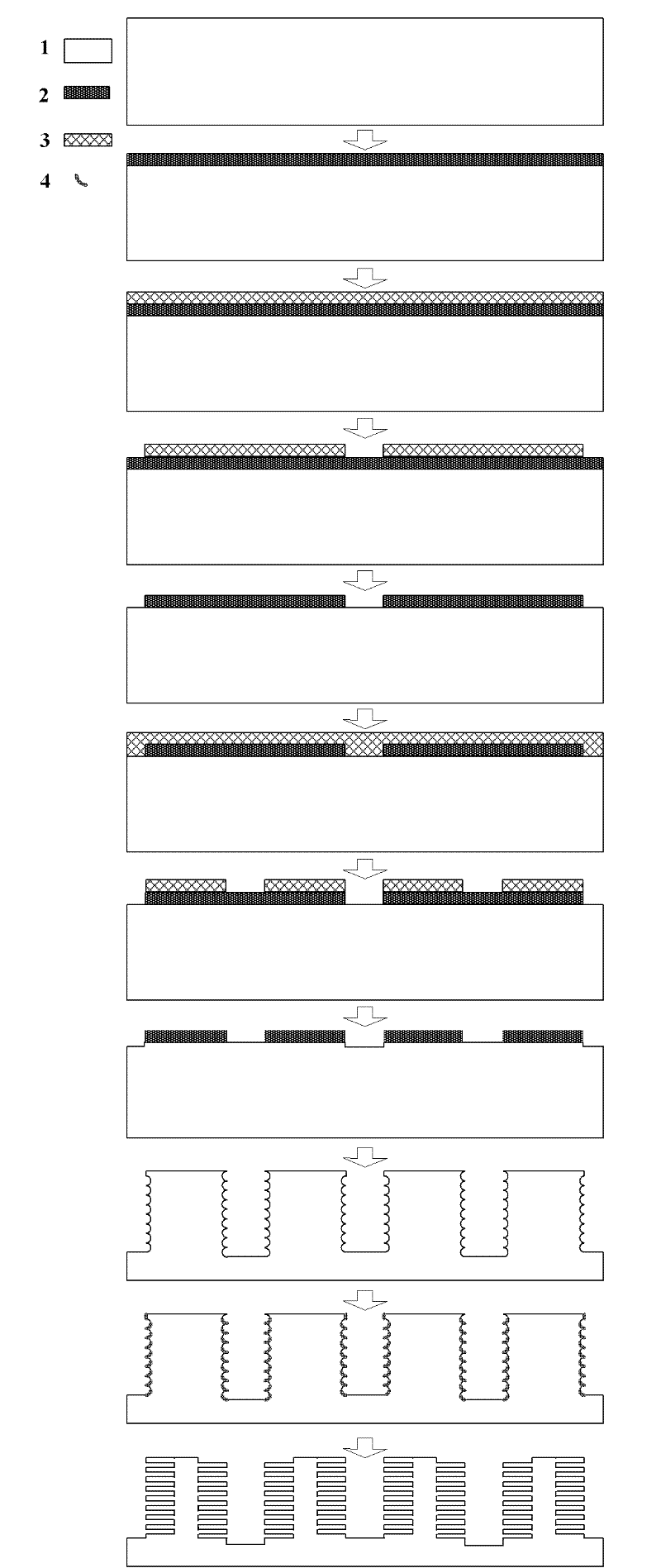

[0019] The embodiment of the present invention is used to prepare the micro-nano structure imitating the surface of butterfly phosphorus wings, and the process flow is shown in figure 1 . Thermal growth of SiO on the surface of Si substrate 2 layer, using two photolithography and RIE dry etching, the two mask patterns are transferred to SiO 2 surface, and make the exposed silicon surface highly inconsistent, laying the foundation for the next step of asymmetric structure preparation. ICP deep etching is used to obtain a periodic / quasi-periodic micro-scale structure, and the side wall must retain sufficient corrugation depth during ICP etching. Then use electron beam oblique evaporation, plate a protective layer on the lower half of the corrugated side wall, and then perform lateral wet anisotropic etching to obtain a hierarchical, multi-laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com