Flumetralin-containing aqueous emulsion composition and preparation method thereof

An aqueous emulsion and composition technology, applied in the field of pesticides, can solve the problems of increased environmental pollution, increased product cost, inconvenient storage and transportation, etc., and achieves the effects of reducing environmental pollution, low cost, and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

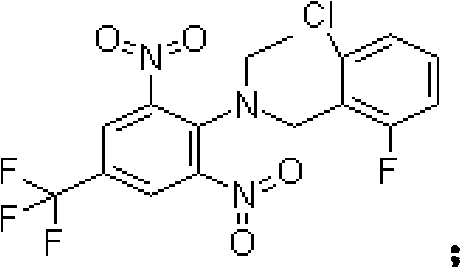

Image

Examples

Embodiment 1

[0027] 25% flumetriamine aqueous emulsion, its composition and percentage by weight are:

[0028] Flumetamine 25%

[0029] First line oil 10%

[0030] Castor oil polyoxyethylene ether (epoxy value 40) 5%

[0031] Calcium dodecylbenzenesulfonate 3%

[0032] Sodium hydroxymethylcellulose 0.3%

[0033] Propylene Glycol 3%

[0034] Defoamer 0.2%

[0035] Deionized water balance.

[0036] Preparation:

[0037] The preparation of water emulsion is carried out in the emulsification tank. The processing procedure is as follows: add the original drug of flubenzamine with a concentration >95% to the first-line oil, fully stir and dissolve in a water bath at 50-70°C, and then add castor oil polyoxyethylene ether and calcium dodecylbenzenesulfonate Mix into a uniform oil phase liquid; stir and mix sodium hydroxymethylcellulose, propylene glycol, defoamer and water to form a uniform water phase liquid; under the action of a 2000 rpm high-shear emulsifier, slowly dissolve the The l...

Embodiment 2

[0039] 40% flumetriamine aqueous emulsion, its composition and percentage by weight are:

[0040] Flumetamine 40%

[0041] Ethyl acetate 10%

[0042] Phenylphenol Polyoxyethylene Polyoxypropylene Ether 8%

[0043] Sodium lauryl sulfate 1%

[0044] Xanthan Gum 0.1%

[0045] Glycerol 1%

[0046] Defoamer 0.1%

[0047] Deionized water balance.

[0048] Preparation:

[0049]In the emulsification kettle, add the original drug of flubenzamine with a concentration >95% into ethyl acetate, fully stir and dissolve in a water bath at 50-70°C, and then add phenylethylphenol polyoxyethylene polyoxypropylene ether and dodecyl Alcohol sodium sulfate is mixed into a uniform oil phase liquid; Xanthan gum, glycerin, defoamer and water are stirred and mixed to form a uniform water phase liquid; under the action of a 500 rpm high-shear emulsifier, slowly The water phase liquid is added to the oil phase, or the oil phase is added to the water phase to form a well dispersed water emulsion....

Embodiment 3

[0051] 10% flumetriamine aqueous emulsion, its composition and percentage by weight are:

[0052] Flumetamine 10%

[0053] Xylene 10%

[0054] Alkylaryl polyoxypropylene polyoxyethylene ether 1%

[0055] Modified Starch 3%

[0056] Propylene Glycol 5%

[0057] Defoamer 0.2%

[0058] Deionized water balance.

[0059] Preparation:

[0060] Firstly, put the original drug of flubenzamine with a concentration >95%, xylene and alkylaryl polyoxypropylene polyoxyethylene ether into an emulsification dispersion kettle, and mix to form a uniform oil phase liquid. Stir together the modified starch, propylene glycol, antifoam, and deionized water to form a homogeneous aqueous liquid. Under the action of a high-shear emulsifier at 1000 rpm, slowly add the water phase liquid into the oil phase, or add the oil phase into the water phase to form a well-dispersed water emulsion. After stirring for 5 minutes, a uniform and flowable white emulsion product was obtained, with an average pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com