Method for synthesizing continuous carbon nanometer tube film

A carbon nanotube thin film and carbon source technology, applied in the field of carbon nanomaterial synthesis, can solve the problems of potential safety hazards, unfavorable large-scale collection of carbon nanotubes, inability to synthesize continuous carbon nanotube filaments and large-scale production, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 0.026g of ferrocene, dissolve it in 12.87g of toluene solution, add 0.1g of thiophene dropwise, and then ultrasonically disperse the mixed solution for 5min to obtain a yellow transparent reaction solution.

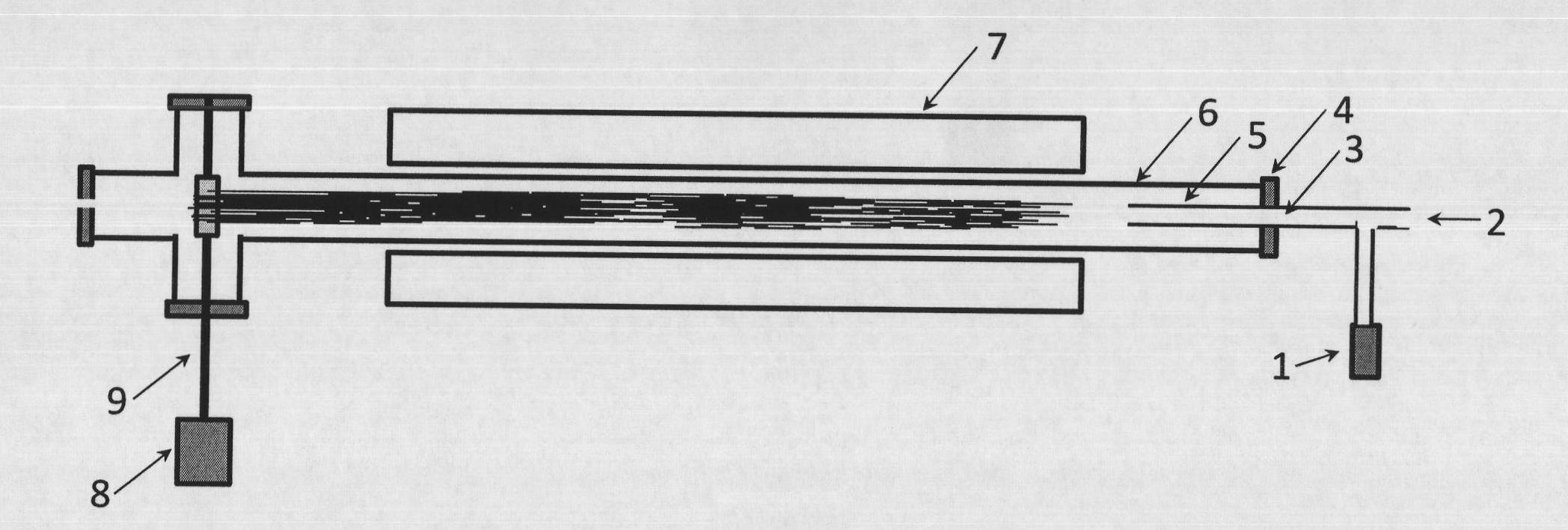

[0032] (2) The temperature of the horizontal reactor is raised to 1000 DEG C at a speed of 10 DEG C / min, and the reaction solution is injected into the airflow of 50 ml / min argon as the carrier gas 2 at a speed of 15 ml / h. , the carbon nanotube film flows out with the airflow, and the rotating shaft 9 at the end of the quartz tube 6 is rotated to obtain the carbon nanotube film.

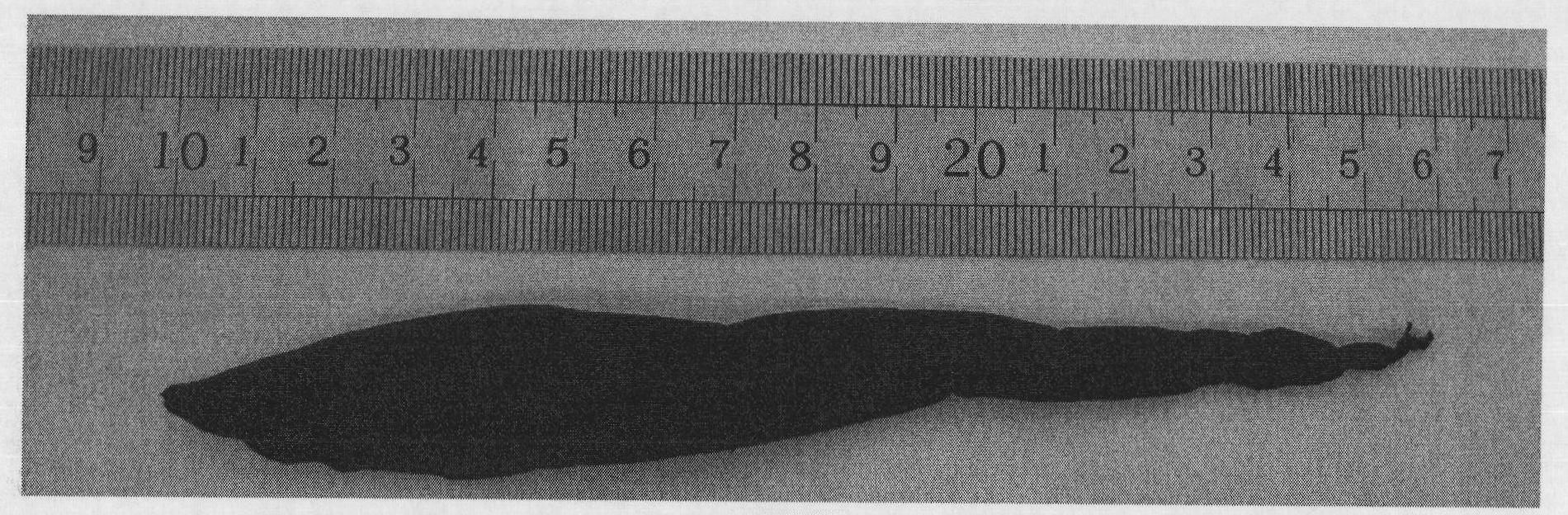

[0033] figure 2 It is a continuously spun carbon nanotube film with a length of about 15cm, a thickness of about 100μm, and a reaction time of 20min.

Embodiment 2

[0035] (1) Weigh 0.78g ferrocene, dissolve it in 11.7g ethanol solution, and add 0.52g thiophene dropwise. Then the mixed solution was ultrasonically dispersed for 5 min to obtain a yellow transparent reaction solution.

[0036] (2) The temperature of the horizontal reactor is raised to 1100°C at a speed of 10°C / min, and the reaction solution is injected into a mixture of 550ml / min hydrogen and argon at a speed of 15ml / h (H 2 : Ar=5:1) in the carrier gas flow 2, in the high-temperature reaction furnace, the carbon nanotube film flows out with the air flow, and the rotating shaft 9 at the end of the quartz tube 6 is rotated to obtain the carbon nanotube film.

Embodiment 3

[0038] (1) Weigh 0.4g of ferrocene, dissolve it in 12.5g of xylene solution, and add 0.26g of thiophene dropwise. Then the mixed solution was ultrasonically dispersed for 5 min to obtain a yellow transparent reaction solution.

[0039] 2) The temperature of the horizontal reactor is raised to 1150°C at a rate of 10°C / min, and the reaction solution is injected into a mixture of 1000ml / min hydrogen and argon at a rate of 15ml / h (H 2 : Ar=10:1) in the carrier gas flow 2, in the high-temperature reaction furnace, the carbon nanotube film flows out with the air flow, and the rotating shaft 9 at the end of the quartz tube 6 is rotated to obtain the carbon nanotube film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com