Preparation method of zeolite molecular sieve monolith with composite pore structure

A zeolite molecular sieve and composite pore technology, which is applied in molecular sieve catalysts, crystalline aluminosilicate zeolites, chemical instruments and methods, etc., can solve the difficulties in the preparation of composite pore structure zeolite materials and the amorphous pore walls of mesoporous materials, etc., to achieve Effects of reducing induction time, improving stability, and lowering reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

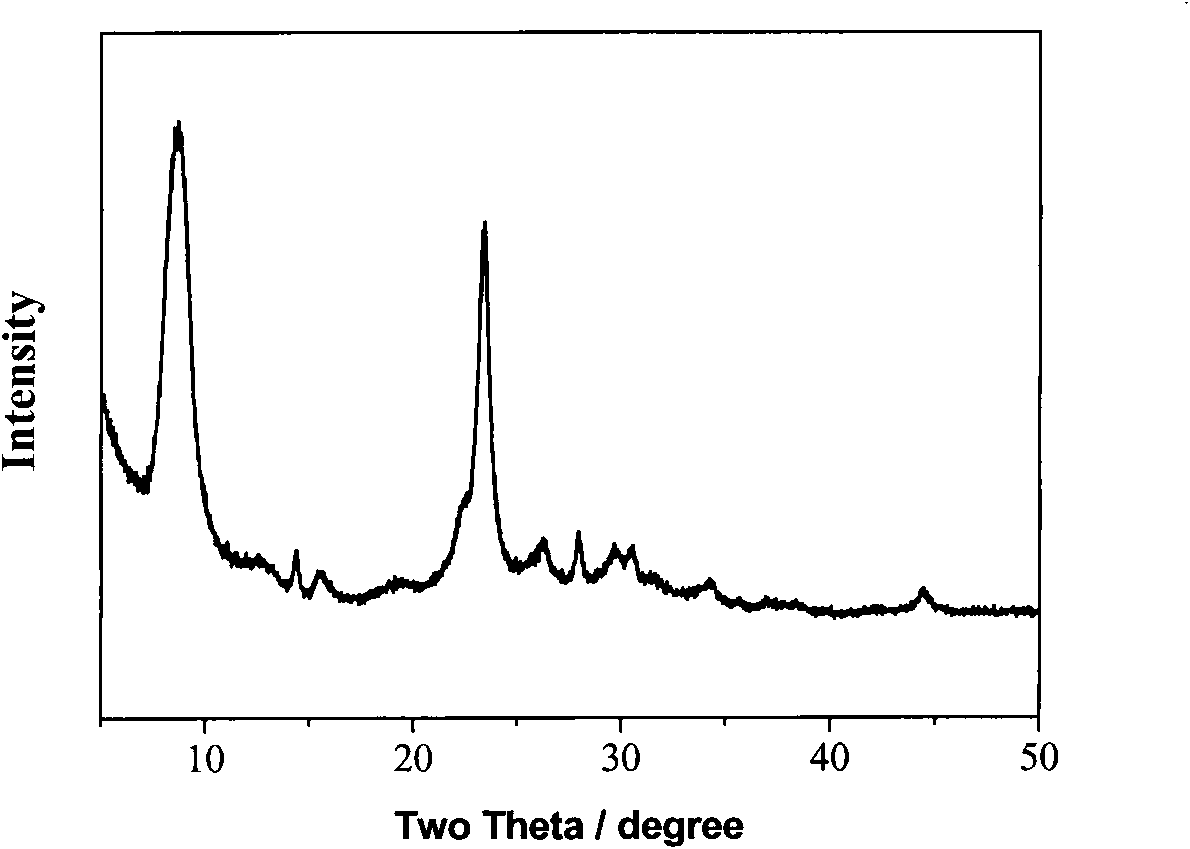

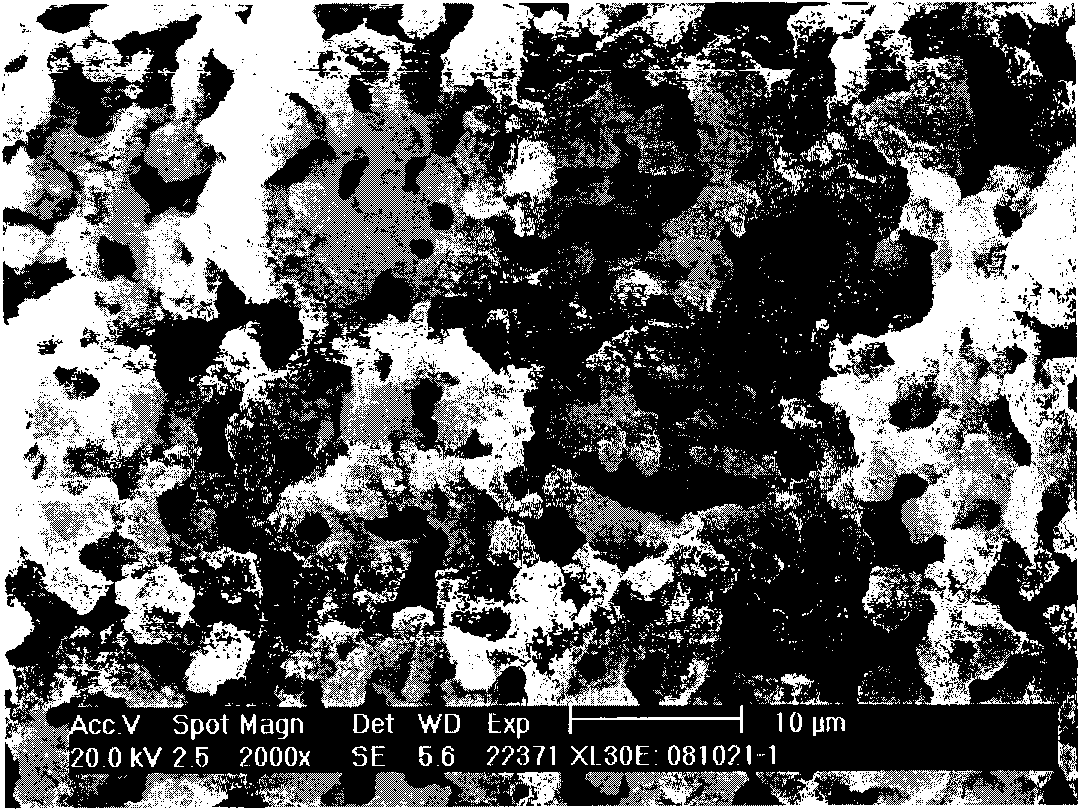

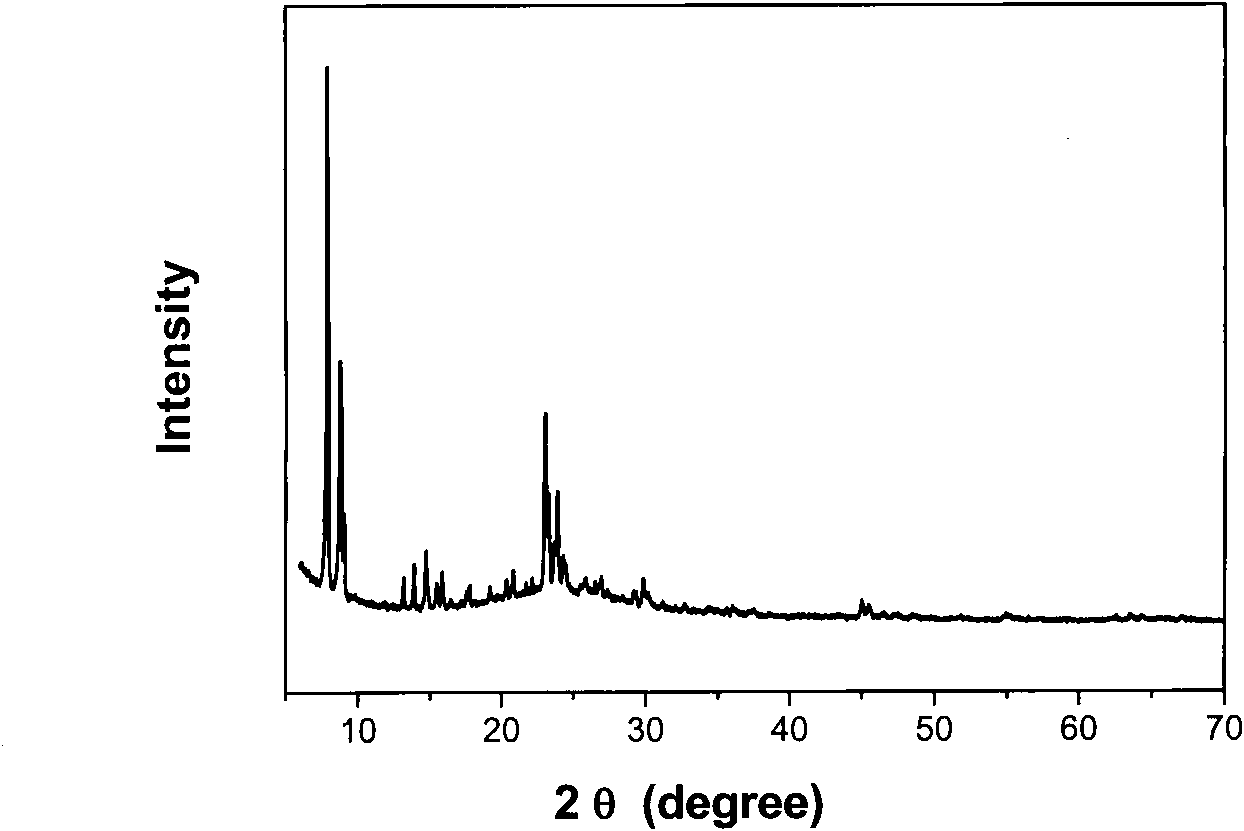

Image

Examples

Embodiment 1

[0027] a) Mix polyethylene glycol, 0.4 mol / liter nitric acid solution and aluminum nitrate, dissolve it and transfer it to an ice-water mixing bath, add tetraethyl orthosilicate, stir for 2 hours, transfer it to a mold and seal it, and react at 60°C 24 hours. Sample A was obtained after demoulding and drying. Among them, the mass ratio of polyethylene glycol / SiO 2 =0.35,H + / SiO 2 =0.16,H 2 O / SiO 2 =2.25, Al 2 o 3 / SiO 2 = 0.004.

[0028]b) Sample A was impregnated dropwise with 0.84 mol / L sulfuric acid solution overnight, dried in sections at 60°C and 170°C, and then roasted at 800°C under nitrogen protection to obtain Sample B. Among them, the mass ratio of sulfuric acid / SiO 2 = 0.1.

[0029] c) Place the sample B in the porous support on the upper layer of the reaction kettle, place a tetraethylammonium hydroxide solution with a volume ratio of 8 to the sample B, and crystallize at 160°C for 6 days.

[0030] After leaving the kettle, the product was washed with ...

Embodiment 2

[0032] a) Mix citric acid, polyoxyethylene-polyoxypropylene-polyoxyethylene, and 1 mol / liter acetic acid solution, dissolve and transfer to an ice-water mixing bath, add tetramethyl orthosilicate, and stir vigorously for 0.1 hour Transfer to a mold to seal, and react at 40°C for 48 hours. After taking it out, it was demolded and dried to obtain sample A. Among them, the mass ratio of citric acid / SiO 2 =0.5, polyoxyethylene-polyoxypropylene-polyoxyethylene / SiO 2 =0.3,H + / SiO 2 =0.25,H 2 O / SiO 2 = 2.5.

[0033] b) Sample A was impregnated overnight in 18.4 mol / L sulfuric acid solution, dried in sections at 120°C and 200°C, and then roasted at 700°C under nitrogen protection to obtain sample B. Among them, the mass ratio of sulfuric acid / SiO 2 = 0.15.

[0034] c) Add sample B to a mixed solution of sodium hydroxide, tetrapropylammonium bromide, aluminum isopropoxide and water, soak it overnight and transfer it to the porous bracket on the upper layer of the reaction ket...

Embodiment 3

[0037] a) Mix polyoxyethylene-polyoxypropylene-polyoxyethylene, 1 mol / liter hydrochloric acid solution and aluminum chloride, add tetrapropyl orthosilicate after dissolving, stir at 40°C for 5 hours, transfer to a mold and seal, Sample A was obtained by reacting at 80° C. for 24 hours. Among them, the mass ratio of polyoxyethylene-polyoxypropylene-polyoxyethylene / SiO 2 = 1.0, H + / SiO 2 =0.2,H 2 O / SiO 2 = 4, Al 2 o 3 / SiO 2 = 0.4.

[0038] b) Remove the sample A and then dry it. Add a mixed solution of sucrose, concentrated sulfuric acid and deionized water, soak overnight at 100°C and 180°C in stages, and bake at 900°C under nitrogen protection to obtain sample B. Among them, the mass ratio of sucrose / SiO 2 =1, sulfuric acid / SiO 2 =0.1, water / SiO 2 =2.

[0039] c) Place the sample B in the porous support on the upper layer of the reaction kettle, place a tetraethylammonium hydroxide solution with a volume ratio of 10 to the sample B, and crystallize at 180° C. fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com