Heat-resistant bacillus and application thereof in preparing phenyl lactic acid

A technology of bacillus and phenyllactic acid, which is applied in the application field of biotransformation of phenylpyruvate to prepare phenyllactic acid, and achieves the effects of low production cost, shortened production cycle, and improved reaction process rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

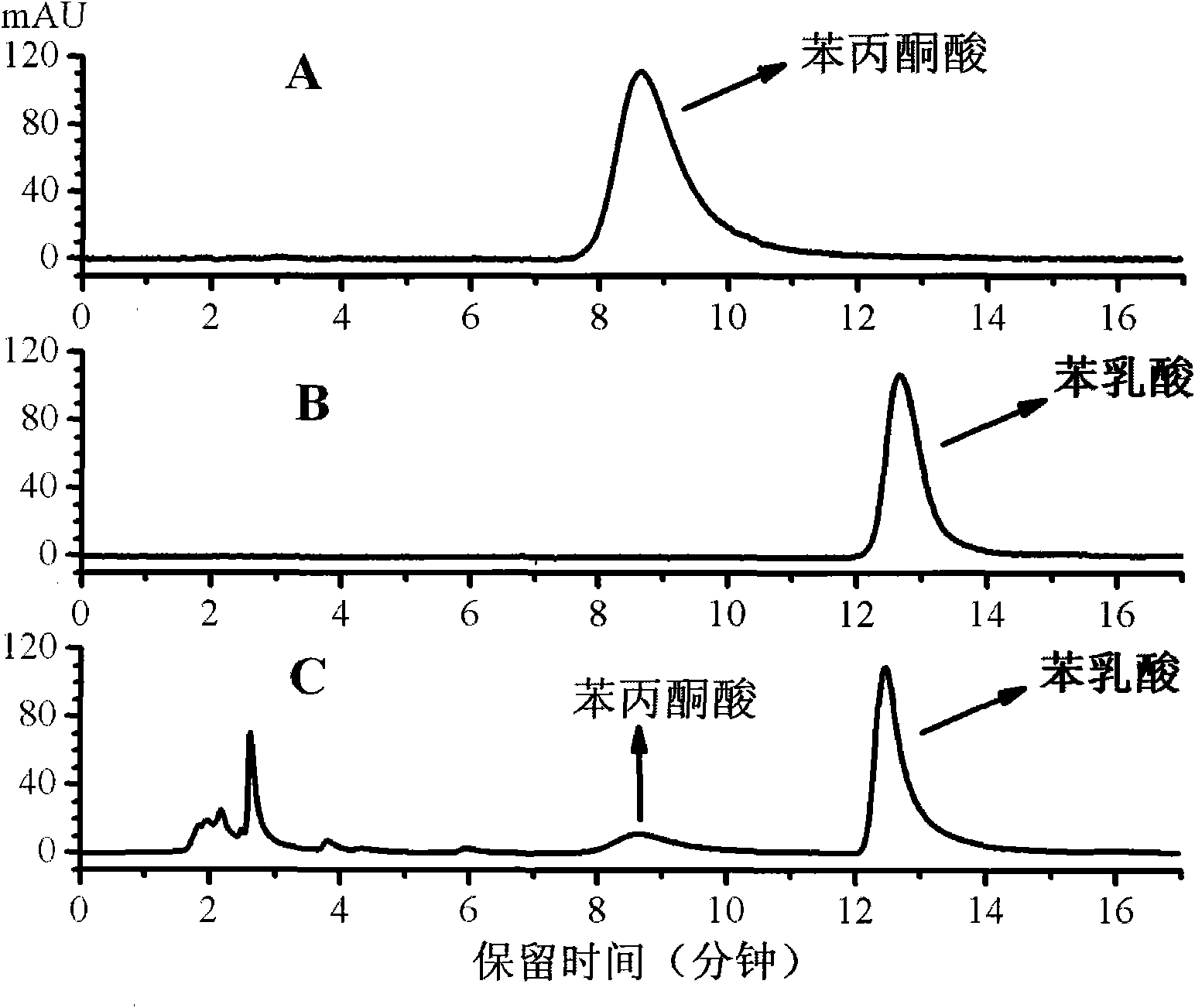

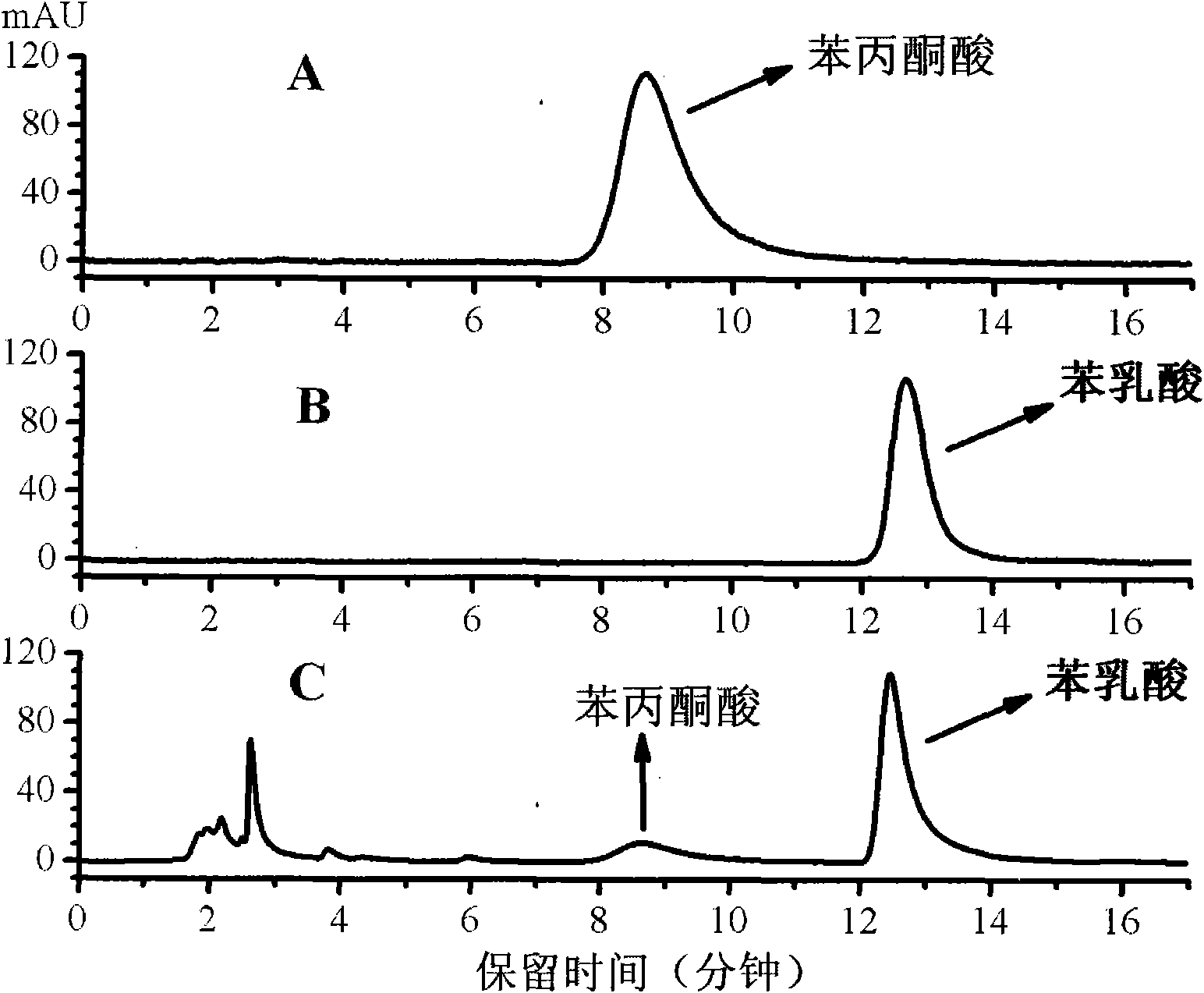

Image

Examples

Embodiment 1

[0036] Screening and identification of Bacillus sp. SDM:

[0037]Obtain soil samples from around the garbage heap where rotten fruits have been stacked for a long time in an orchard, weigh 2 grams of soil samples and put them into 50 ml of liquid medium, 100 rpm, 55 ° C for 8 to 10 hours of enrichment culture, and then add a mass-volume ratio of 1% phenylpyruvate, shake culture at 100 rpm for 10 hours, repeat this process 3-5 times. The cultured bacterial solution was diluted 10,000,000 times, spread on the solid medium, and cultured statically at 55°C for 12 hours. Select the grown single colony and inoculate it into 50 ml of fermentation medium, add 1% phenylpyruvate in a mass-volume ratio after shaking for 10 hours, and detect the content of phenyllactic acid generated after shaking at 100 rpm for 15 hours to screen for transformation Phenylpyruvate A strain that produces phenyllactic acid. Finally, a strain with better transformation ability and a large amount of accumul...

Embodiment 2

[0042] Utilize heat-resistant bacillus (Bacillus sp.) SDM CCTCC No.M 2010012 whole cell catalytic system to convert phenylpyruvate to prepare phenyllactic acid, the method steps are as follows:

[0043] (1) Slant culture: inoculate the heat-resistant Bacillus sp. SDM CCTCC No.M 2010012 on the solid slant medium, and culture it statically for 10 hours at 55°C;

[0044] (2) Seed culture: Scrape the slant culture obtained in step (1) of 2 rings and inoculate it into 300 milliliters of liquid seed culture medium. Under the conditions of 55°C and pH value 7.0, vibrate at 100 rpm for 11 hours to prepare Obtain seed culture fluid;

[0045] (3) Preparation of cell suspension: get the seed culture solution of step (2) gained, insert in 8 liters of fermentation medium by the inoculum size of 4% volume ratio; Under the condition of 55 ℃, pH value 7.0, 100 Shake culture for 11 hours at rpm; then centrifuge at 4,500 rpm for 15 minutes to collect the bacterial pellet, and resuspend with 50...

Embodiment 3

[0053] Utilize heat-resistant bacillus (Bacillus sp.) SDM CCTCC No.M 2010012 whole cell catalytic system to convert phenylpyruvate to prepare phenyllactic acid, the method steps are as follows:

[0054] (1) Slant culture: Bacillus sp.SDM CCTCC No.M 2010012 was inoculated onto a solid slant medium, and cultured statically for 12 hours at 50°C;

[0055] (2) Seed culture: Scrape the slant culture obtained in step (1) of 1 ring, inoculate it into 200 milliliters of liquid seed culture medium, and culture it with shaking at 100 rpm for 11 hours at 50°C and a pH value of 6.0. Prepare the seed culture solution;

[0056] (3) Preparation of cell suspension: get the seed culture solution of step (2) gained, insert in 7 liters of fermentation medium by the inoculum size of 3.5% volume ratio; Under the condition of 50 ℃, pH value 6.0, 100 Shake culture for 10 hours at rpm; then centrifuge at 4,500 rpm for 15 minutes to collect the bacterial pellet, and resuspend with 50 mM, pH 7.0 phosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com