Making process of leather-like paper with high wet strength

A production process and technology of imitation leather paper, which is applied in the directions of surface covering paper and reinforcing agent addition to achieve the effects of high wet strength, improved paper strength and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In conjunction with the accompanying drawings, the present invention will be described in further detail below.

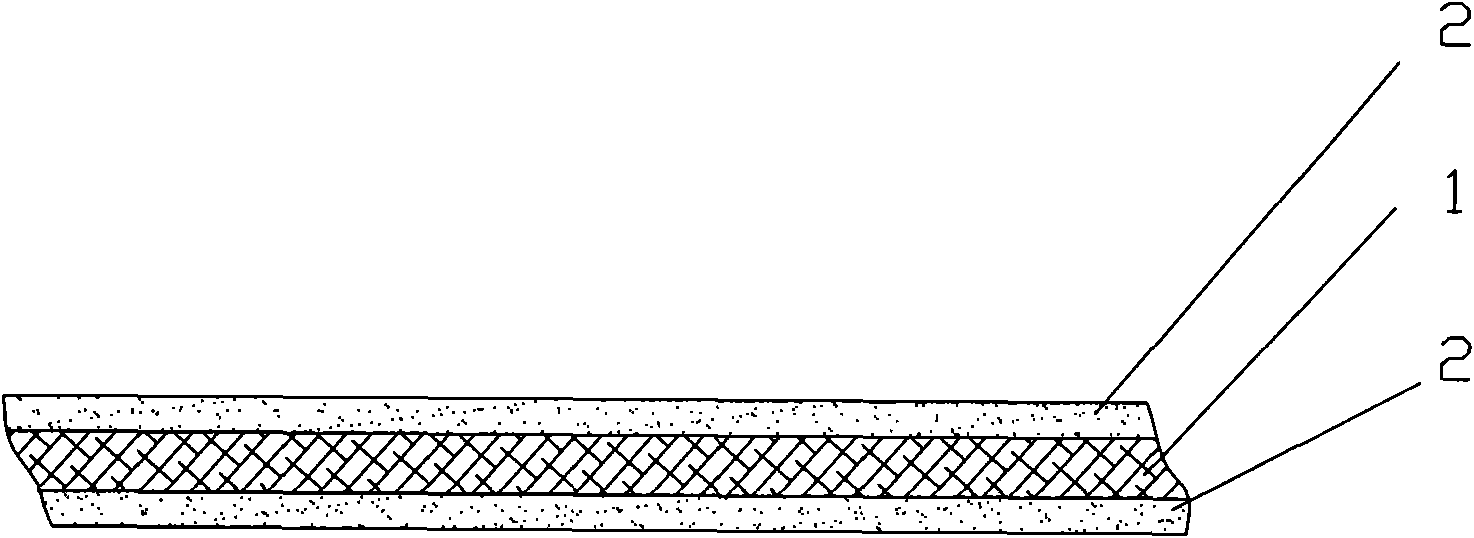

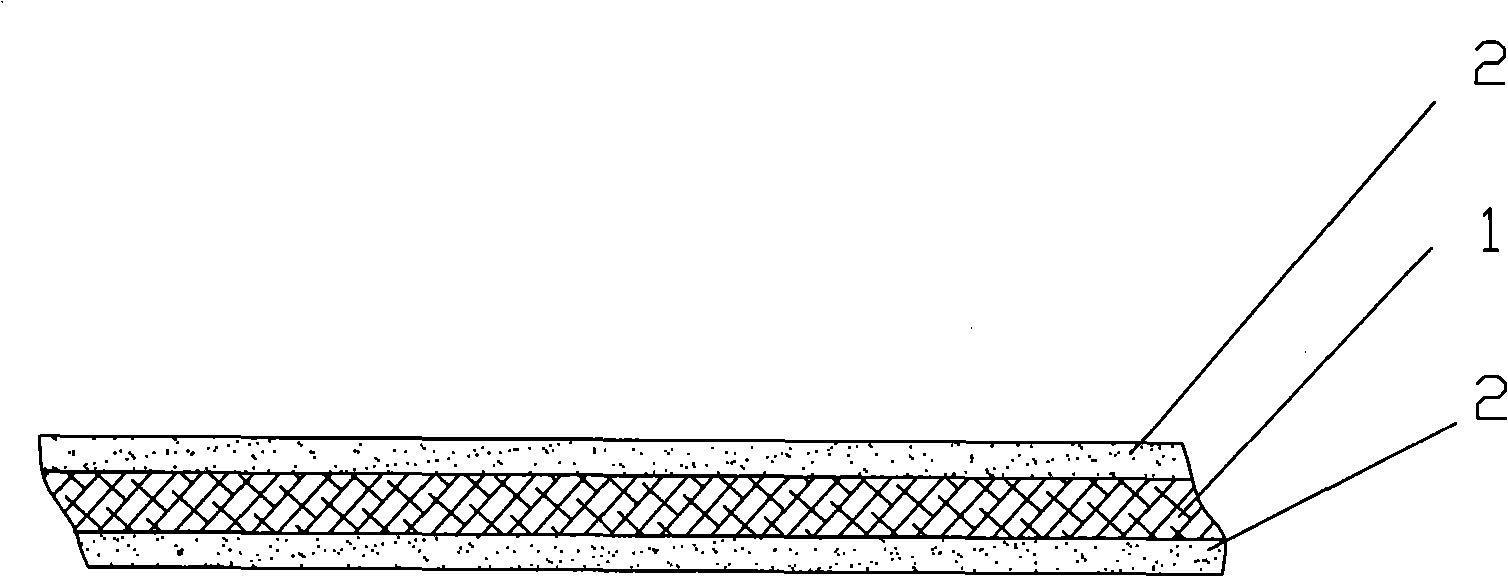

[0020] like figure 1 As shown, the high wet strength imitation leather paper of the present invention, the middle layer is base paper base 1, and the outer surface of base paper base 1 is evenly coated with one deck latex layer 2, and this latex layer 2 is made of silicone propane, carboxylated styrene-butadiene emulsion, benzene It is composed of at least one of acrylic emulsion, water-based polyurethane emulsion, and acrylic emulsion.

[0021] The process of this specific embodiment of the invention is as follows:

[0022] 1. At first select reasonable pulp proportioning: wherein cotton pulp or hemp pulp, Manila hemp pulp account for 30%-80%, and coniferous wood pulp accounts for 20%-70%; Be 60% Manila hemp pulp in the present embodiment and 40% softwood pulp.

[0023] 2. Add 1%-1.5% (on fiber) wet strength agent to the above pulp, which can be one or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com