Flexible transparent conducting film for polyimide substrate and preparation method thereof

A technology of transparent conductive film and polyimide, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., and can solve problems affecting the transmittance of transparent conductive film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

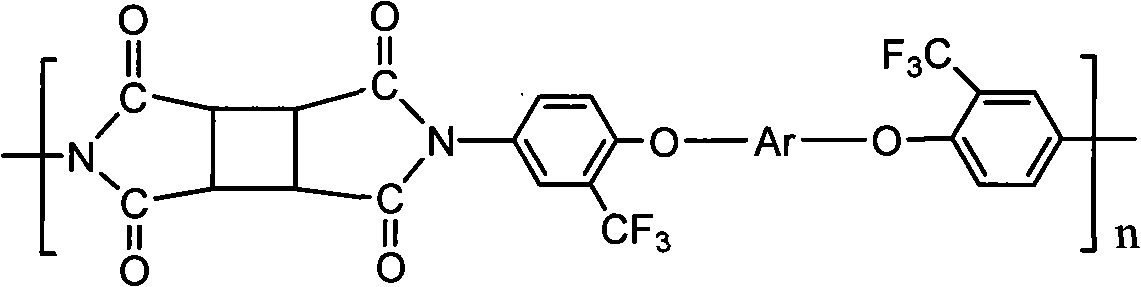

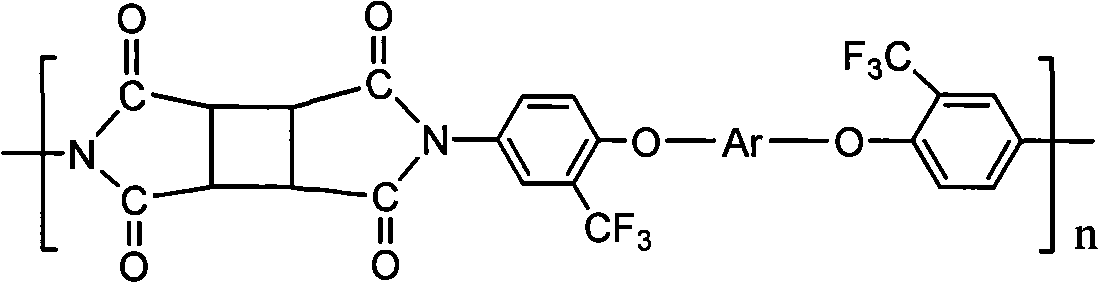

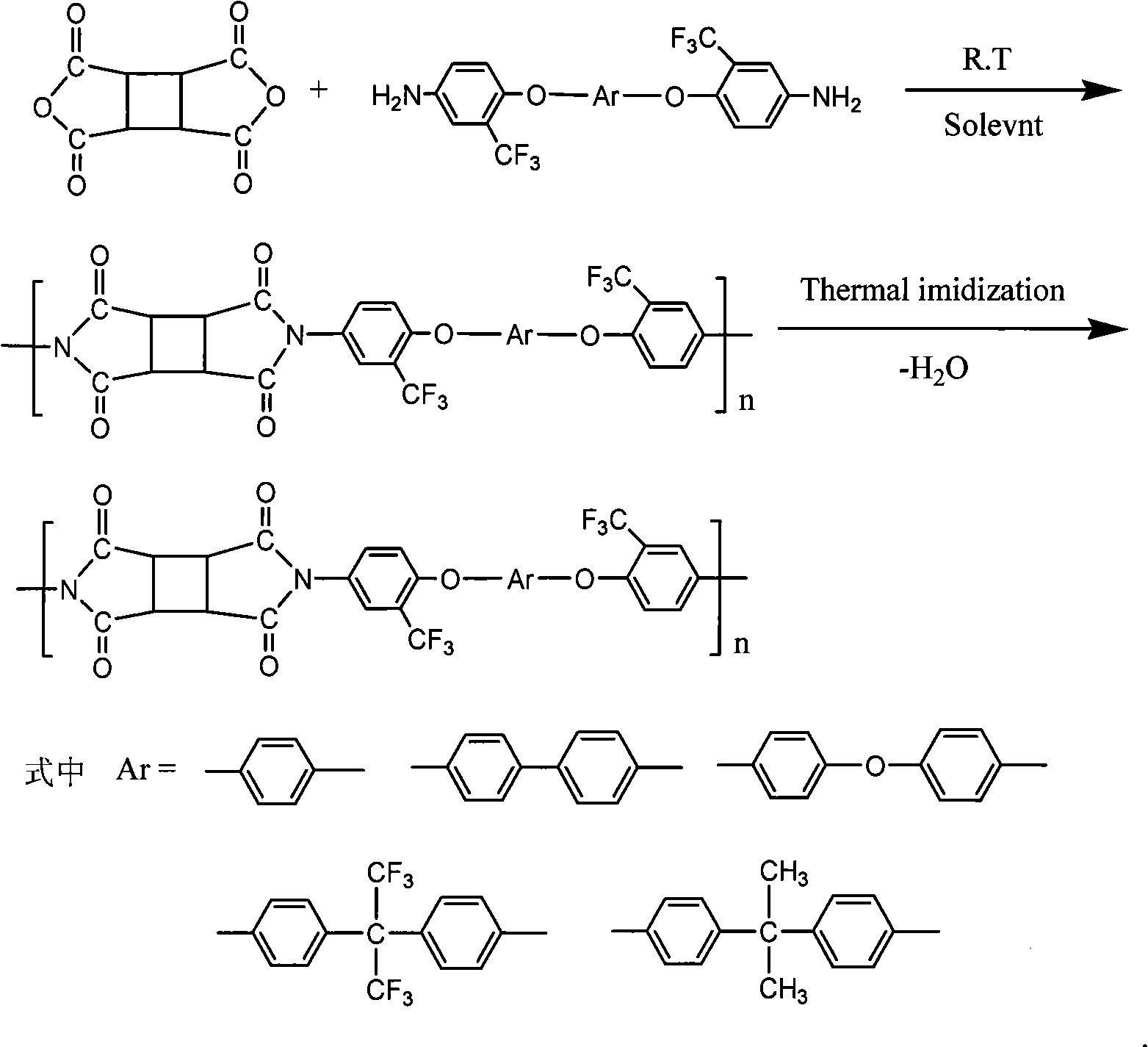

Method used

Image

Examples

Embodiment 1

[0036]In a three-necked reaction flask equipped with a stirrer, a thermometer and a nitrogen inlet, 4.2833 g (0.01 mol) of 1,4-bis(4-amino-2-trifluoromethylphenoxy)benzene was dissolved in 37.72 ml N, N-dimethylacetamide solvent, stirring to make the solution clear and transparent. Then add 1.9611g (0.01mol) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride (CBDA) to the solution at one time, stir to make it completely dissolved and continue the reaction for 15-25 Hours, a transparent viscous liquid-polyamic acid solution was obtained, the solid content by weight was 15wt%, and the intrinsic viscosity was 1.26dL / g. Coat the polyamic acid solution on a clean glass plate, place it in a drying oven with nitrogen protection, and heat up according to the following program: 80°C for 2hrs, 120°C for 1hr, 150°C for 1hr, 200°C for 1hr, and 250°C 1hr, 0.5hr at 250°C. After the temperature dropped to room temperature, the glass plate was taken out and placed in warm water to remove the...

Embodiment 2

[0039] In a three-necked reaction flask equipped with a stirrer, a thermometer and a nitrogen inlet, 5.0442 g (0.01 mol) of 4,4'-bis(4-amino-2-trifluoromethylphenoxy)biphenyl was dissolved in 42.32ml of N,N-dimethylacetamide solvent, stirred to make the solution clear and transparent. Then, 1.9611 g (0.01 mol) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride (CBDA) was added to the solution at one time, stirred to dissolve it completely, and continued to react for 15 to 25 minutes under a nitrogen protection environment. Hours, a transparent viscous liquid-polyamic acid solution was obtained, the solid content by weight was 15wt%, and the intrinsic viscosity was 1.20dL / g. Coat the polyamic acid solution on a clean glass plate, place it in a drying oven with nitrogen protection, and heat up according to the following program: 80°C for 2hrs, 120°C for 1hr, 150°C for 1hr, 200°C for 1hr, and 250°C 1hr, 0.5hr at 300°C. After the temperature dropped to room temperature, the glass...

Embodiment 3

[0042] In a three-necked reaction flask equipped with a stirrer, a thermometer and a nitrogen inlet, 5.2042 g of 2,2-bis[4-(4-amino-2-trifluoromethylphenoxy)phenyl]diphenyl ether (0.01mol) was dissolved in 43.29ml of N,N-dimethylacetamide solvent, stirred to make the solution clear and transparent. Then, 1.9611 g (0.01 mol) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride (CBDA) was added to the solution at one time, stirred to dissolve it completely, and continued to react for 15 to 25 minutes under a nitrogen protection environment. Hours, a transparent viscous liquid-polyamic acid solution was obtained, the solid content by weight was 15wt%, and the intrinsic viscosity was 1.23dL / g. Coat the polyamic acid solution on a clean glass plate, place it in a drying oven with nitrogen protection, and heat up according to the following program: 80°C for 2hrs, 120°C for 1hr, 150°C for 1hr, 200°C for 1hr, and 250°C 1hr, 0.5hr at 300°C. After the temperature dropped to room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com