Metal nickel powder and preparation method thereof

A technology of metal nickel powder and nickel powder, which is applied in the field of metal nickel powder and its preparation, can solve problems such as gaps and incomplete nickel powder, and achieve the effects of long service life, simple production equipment, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

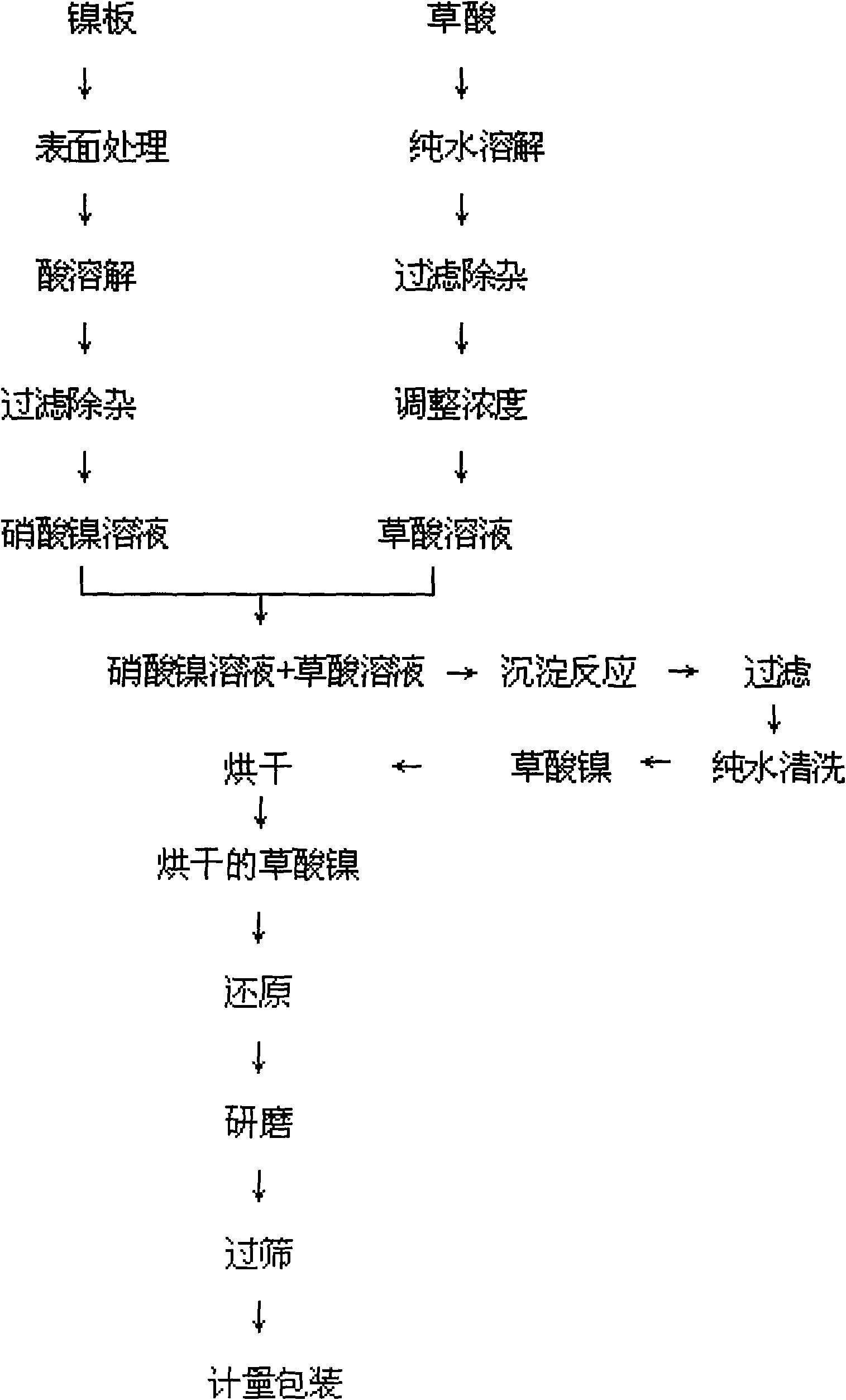

Method used

Image

Examples

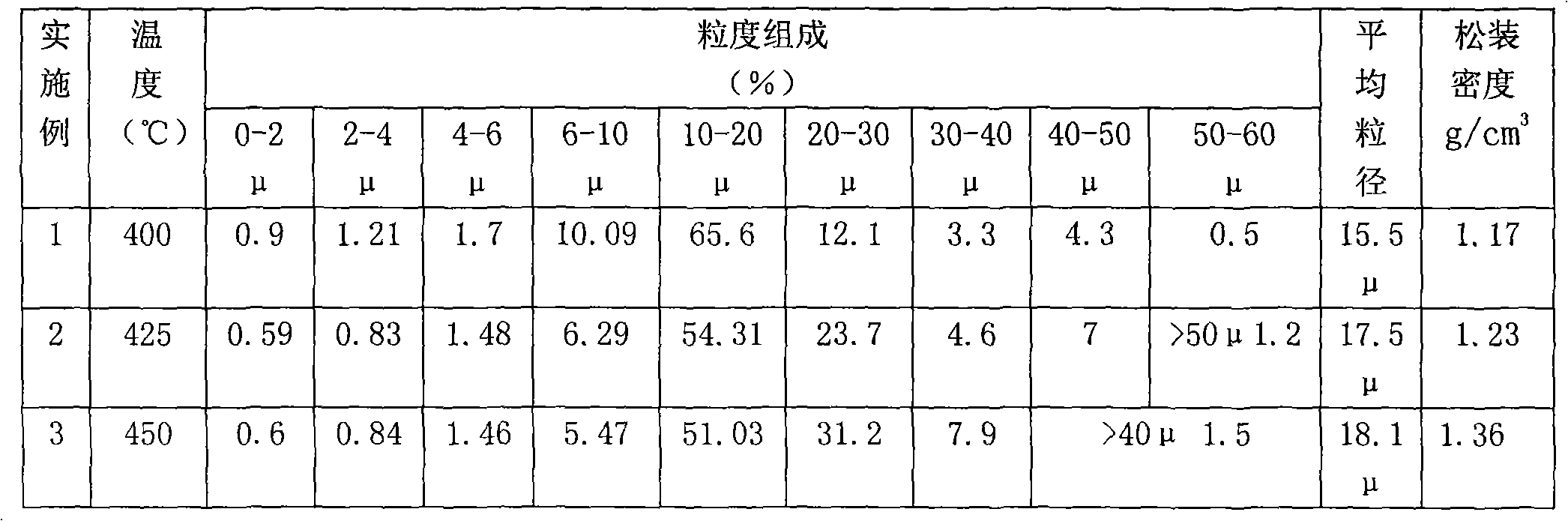

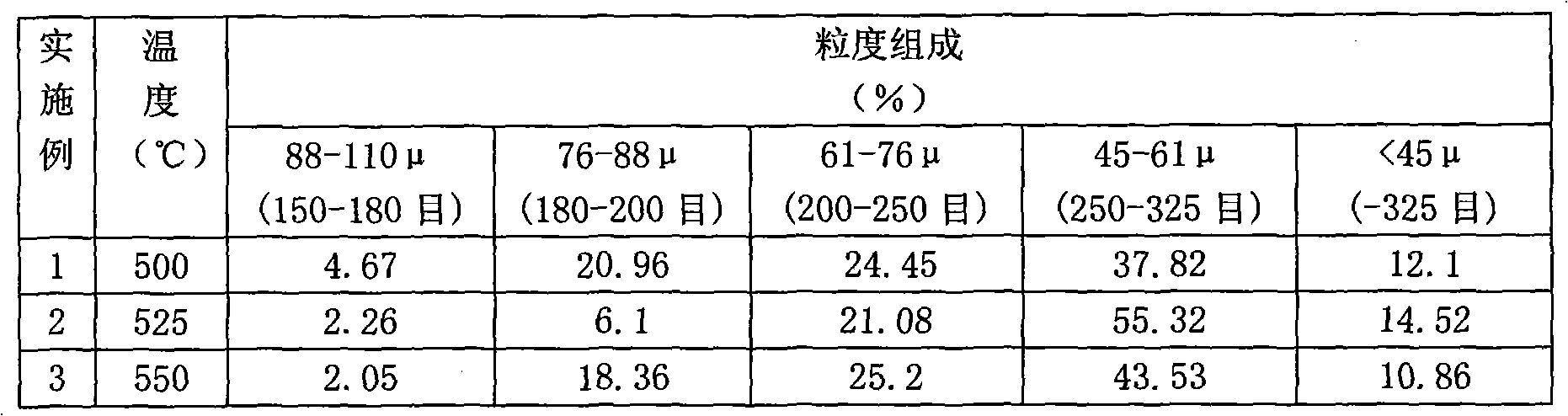

Embodiment 1

[0035] Embodiment 1: the preparation of metallic nickel powder

[0036] Specific steps

[0037] 1. Put the 0# nickel plate in 10% dilute nitric acid solution for pretreatment to remove surface impurities, and then dissolve it in nitric acid with a concentration range of 60% to make nickel nitrate with a concentration range of 1.35-1.45g / ml saline solution;

[0038] 2. Filtrate the nickel nitrate salt solution, remove impurities, add oxalic acid solution with a concentration range of 35%, and keep stirring to obtain nickel oxalate precipitation;

[0039] 3. Wash the nickel oxalate precipitate with ionized water, dry it at 100°C for 3-4 hours, put the nickel oxalate precipitate into the nickel boat and place it in the reduction furnace, control the temperature at 400 plus or minus 5°C, and put the oxalic acid under the control of the hydrogen atmosphere Nickel reduction takes 120 minutes, and the reduction time normally fluctuates around 10 minutes;

[0040] 4. Mill the pyrol...

Embodiment 2

[0044] Embodiment 2: the preparation of metal nickel powder

[0045] Specific steps

[0046] 1. Pretreat the nickel plate in 10% dilute nitric acid solution to remove surface impurities, and then dissolve it in 60% nitric acid to make a nickel nitrate salt solution with a concentration range of 1.35-1.45g / ml ;

[0047] 2. Filtrate the nickel nitrate salt solution, remove impurities, add oxalic acid solution with a concentration range of 35%, and keep stirring to obtain nickel oxalate precipitation;

[0048] 3. Wash the nickel oxalate precipitate with ionized water, dry at 100°C for 3-4 hours, put the nickel oxalate precipitate into a nickel boat and place it in a reduction furnace, control the temperature at 425 plus or minus 5°C, and oxalate under the control of a hydrogen atmosphere Nickel reduction takes 120 minutes, and the reduction time normally fluctuates around 10 minutes;

[0049] 4. The pyrolysis reduction product is crushed with a high-energy stirring ball mill f...

Embodiment 3

[0053] Embodiment 3: the preparation of metal nickel powder

[0054] Specific steps

[0055] 1. Pre-treat the nickel plate in 10% dilute nitric acid solution to remove surface impurities, and then dissolve it in 60% nitric acid to make a nickel nitrate salt solution with a concentration range of 1.35-1.45g / ml ;

[0056] 2. Filtrate the nickel nitrate salt solution, remove impurities, add oxalic acid solution with a concentration range of 35%, and keep stirring to obtain nickel oxalate precipitation;

[0057] 3. Wash the nickel oxalate precipitate with ionized water, dry at 100°C for 3-4 hours, put the nickel oxalate precipitate into the nickel boat and place it in the reduction furnace, control the temperature at 450 plus or minus 5°C, and put the oxalic acid under the control of the hydrogen atmosphere Nickel reduction takes 120 minutes, and the reduction time normally fluctuates around 10 minutes;

[0058] 4. The pyrolysis reduction product is crushed with a high-energy s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com