Method for constructing artificial wetland through aged refuse for processing sewage

A technology of mineralized garbage and artificial wetlands, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve undiscovered problems, achieve convenient construction, strong purification capacity, investment and operating costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

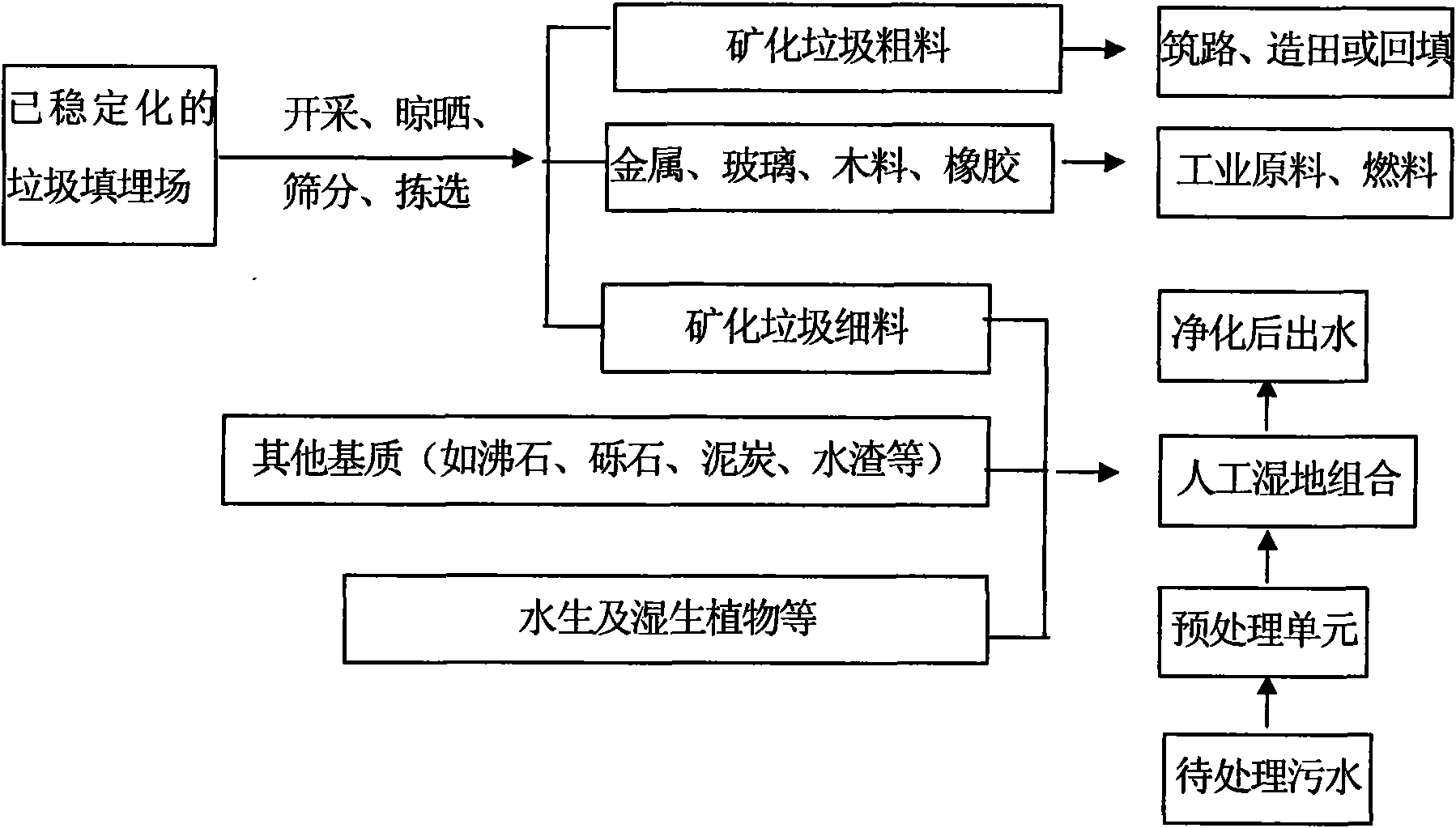

Method used

Image

Examples

Embodiment 1

[0040] The mineralized waste is taken from the landfill unit that has been closed for 13 years. The surface settlement of the landfill site is 8mm / a, the amount of leachate and gas produced by the landfill unit itself is very small, and the mass fraction of biodegradable substances in the waste 5%, and the mass concentration ρ(COD) of COD in the leachate is below 80mg / L, the closure unit is basically in a stable state.

[0041] After the mineralized waste is excavated, dried, screened and sorted, large debris such as stones and wood are used for road construction, field reclamation or site backfill; valuable materials such as glass, metal, rubber and plastic are used as industrial Raw materials or fuels; fine materials with a particle size of less than 15mm and less than 40mm are used as the basic matrix of the constructed wetland and stored for future use.

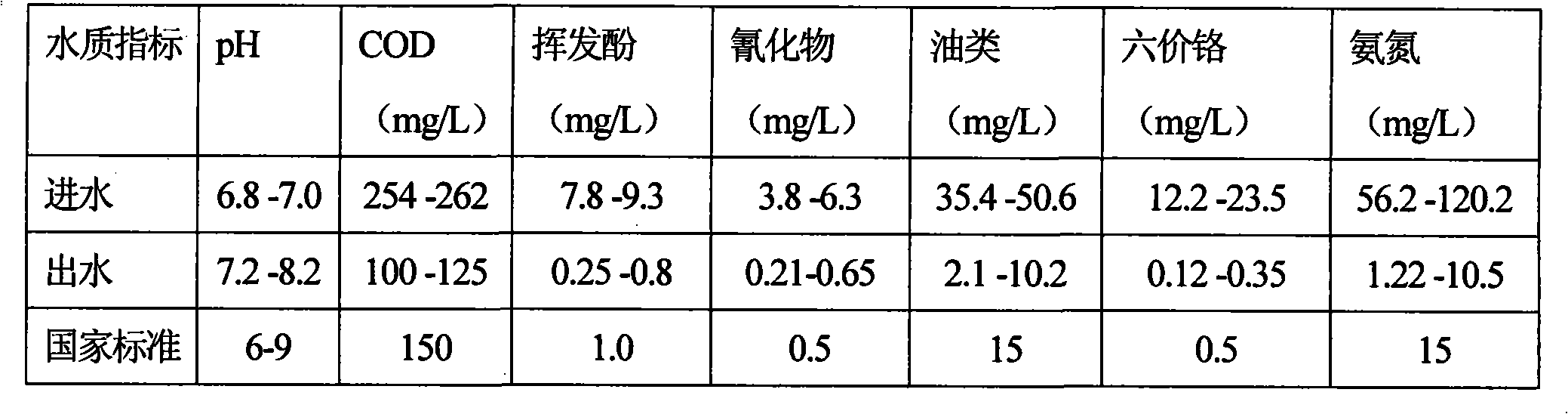

[0042] Constructed wetland is a single-stage vertical subsurface flow constructed wetland with a length of 200cm and a ...

Embodiment 2

[0050] The mineralized waste is taken from the landfill unit that has been closed for 5 years. The surface settlement of the landfill site is 10mm / a, the amount of leachate and gas produced by the landfill unit itself is very small, and the mass fraction of biodegradable substances in the waste The mass concentration of COD in the leachate ρ(COD) is 90-120 mg / L, and the closure unit is basically in a stable state.

[0051] After the mineralized waste is excavated, dried, screened and sorted, large debris such as stones and wood are used for road construction, field reclamation or site backfill; valuable materials such as glass, metal, rubber and plastic are used as industrial Raw materials or fuels; fine materials with a particle size of less than 15mm and less than 40mm are used as the basic matrix of the constructed wetland and stored for future use.

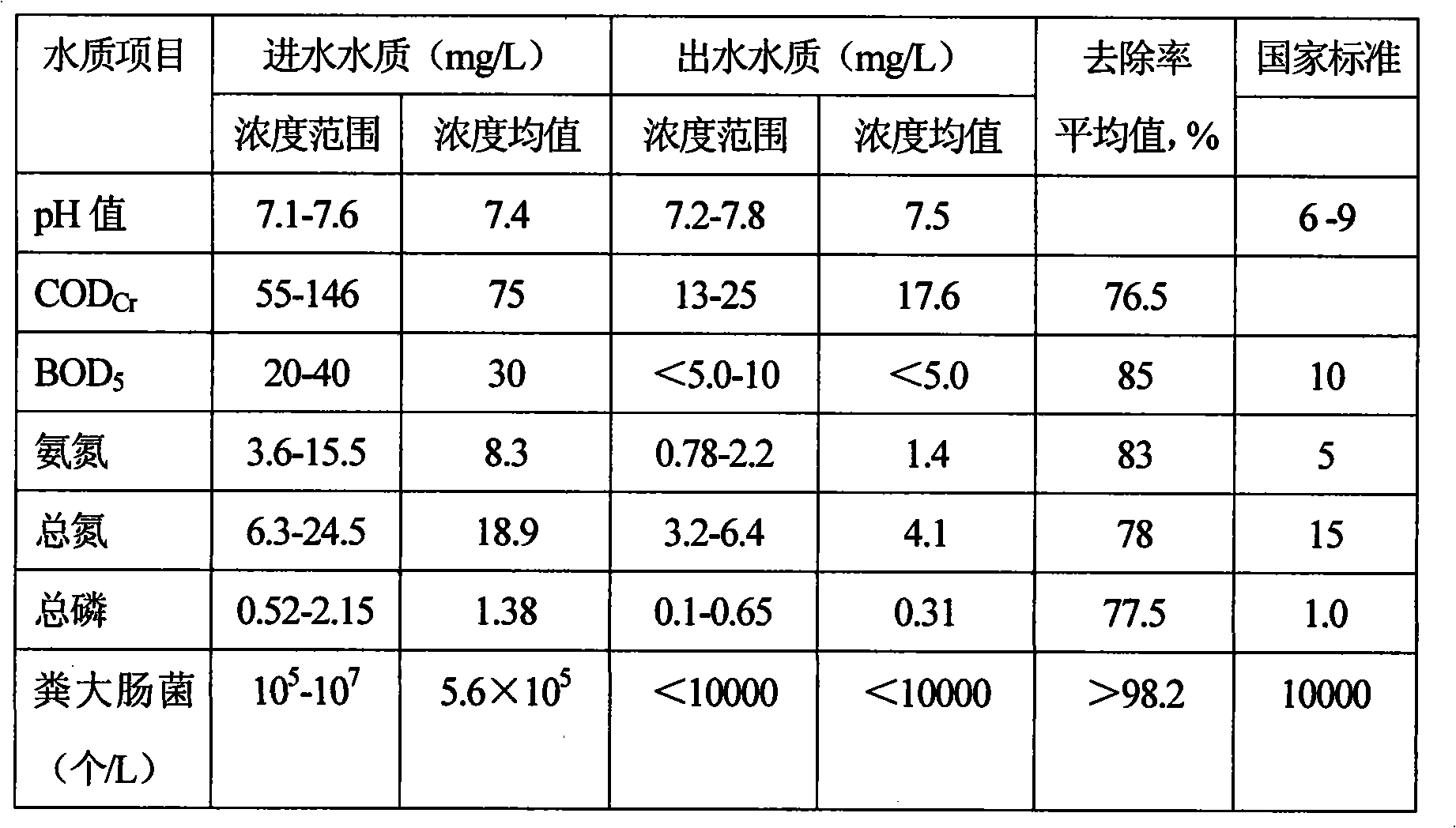

[0052] The sewage to be treated is eutrophic river water. The sewage first passes through the coarse and fine screens for so...

Embodiment 3

[0061] The mineralized waste is taken from the landfill unit that has been closed for 10 years. The surface settlement of the landfill site is 10mm / a, the amount of leachate and gas produced by the landfill unit itself is very small, and the mass fraction of biodegradable substances in the waste 4%, and the mass concentration ρ(COD) of COD in the leachate is below 90mg / L, the closure unit is basically in a stable state.

[0062] After the mineralized waste is excavated, dried, screened and sorted, large debris such as stones and wood are used for road construction, field reclamation or site backfill; valuable materials such as glass, metal, rubber and plastic are used as industrial Raw materials or fuels; fine materials with a particle size of less than 15mm and less than 40mm are used as the basic matrix of the constructed wetland and stored for future use.

[0063] The feces and sewage from the pig farm first pass through the grid for solid-liquid separation, and filter out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com