Bacillus subtilis and alkali-resisting and salt-resisting oil field fracturing enzyme and application thereof

A Bacillus subtilis, oil field fracturing technology, applied in the directions of enzymes, bacteria, microorganism-based methods, etc., can solve the problems of long gel breaking time, difficult gel breaking effect, and pH impact, etc. The effect of easy availability of raw materials and convenient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

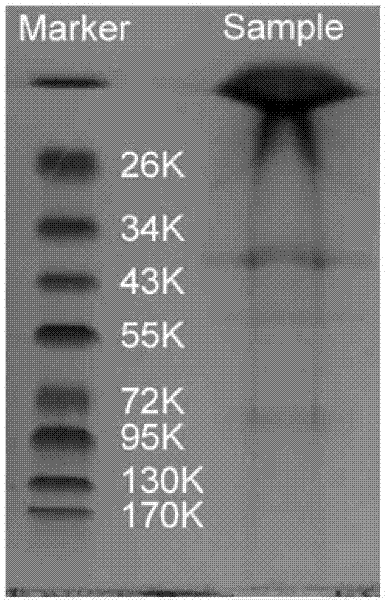

[0047] Example 1: Mix 1.0 g of tryptone, 0.5 g of yeast extract, and 1.0 g of NaCl with 100 mL of water, adjust the pH to 7.0, prepare a seed liquid medium, and sterilize. Inoculate one loop of the slant strain of Bacillus subtilis (BIT09L1) into the seed liquid medium, and culture continuously at 37°C and 200r / min for 24h to obtain 100mL of seed liquid. L-glutamic acid 5.0, KH 2 PO 4 1.0, MgSO 4 · 7H 2 O 0.5, KC1 0.5, MnSO 4 5×10 -5 , FeSO 4 · 7H 2 O 1.5×10 -6 , CuSO 4 · 5H 2 O 1.6×10 -8 1. Mix 0.5g of konjac powder or guar gum with 100mL of water, adjust the pH to 7.0, sterilize, add 5mL of seed solution, shake well, and culture in a constant temperature shaker at 37°C and 150r / min for 48h to obtain a fermentation broth. The fermentation broth was centrifuged at 8000r / min for 20min to remove bacteria and other impurities to obtain the supernatant crude enzyme solution. Add ammonium sulfate to the crude enzyme solution to 65% saturation, place it at 4°C for 24...

Embodiment 2

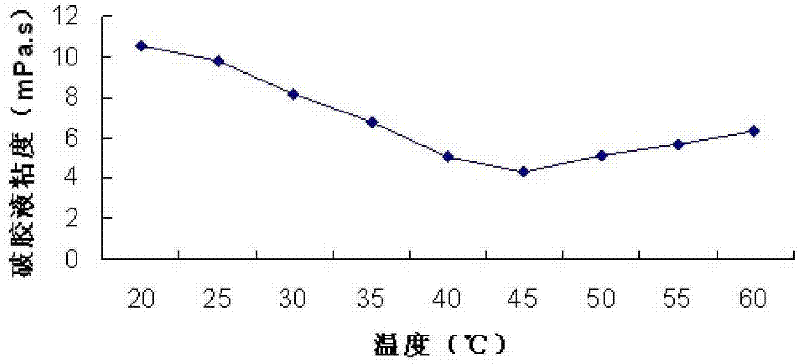

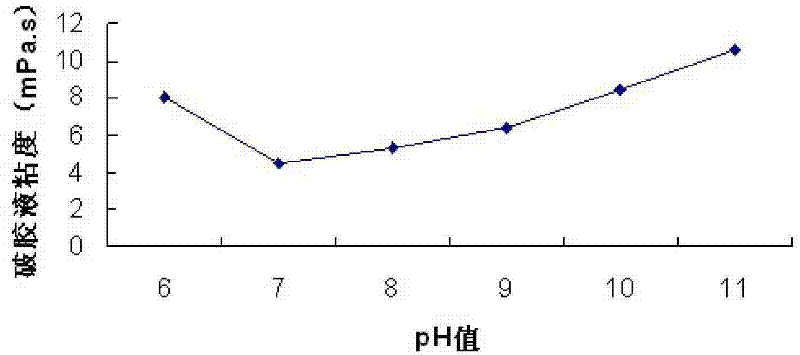

[0057] Embodiment 2: Weigh 4.0g of hydroxypropyl guar gum powder, slowly add it into 1000mL water while stirring, after stirring for 10 minutes, the guar gum dissolves evenly, swell at room temperature for 2 hours, and add fracturing fluid formula assistants in turn to help Discharge agent (HY-05) 5.0mL, anti-swelling agent (DW-1) 3mL, fungicide (S-100) 0.5mL, sodium carbonate 1.0g, stir well, the obtained is the fracturing fluid base fluid, the pH value is Around 10.0. Take 0.5g of glutamic acid and 0.5g of aspartic acid, dissolve them in 5mL of distilled water respectively, and prepare a 10% solution. Take 100mL of fracturing fluid base fluid for each experimental sample, adjust the pH value to 9.0 with acetic acid, glutamic acid, aspartic acid, hydrochloric acid, and gluconic acid respectively, and use the fracturing fluid base fluid sample (pH9.0) as a blank control , in each sample, add the enzyme concentrated solution of embodiment 1 gained respectively so that its final ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com