Polymer isolating membrane and lithium ion battery applying same

A technology of lithium-ion batteries and polymers, applied in battery electrodes, secondary batteries, battery pack components, etc., can solve the problems of not having ionic conductivity, mechanical strength and interface stability at the same time, and achieve good ion transmission performance And electrochemical stability, good stability, good pore structure and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

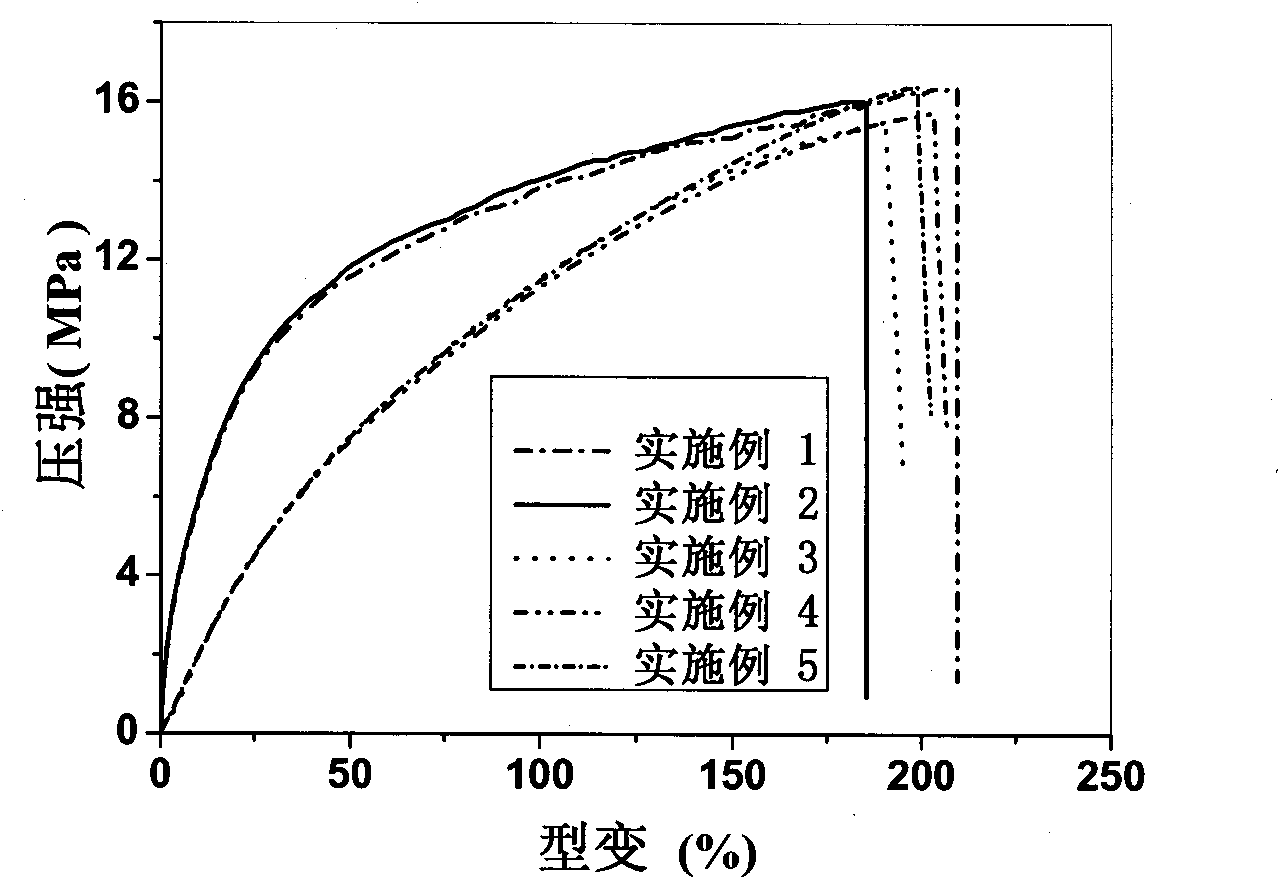

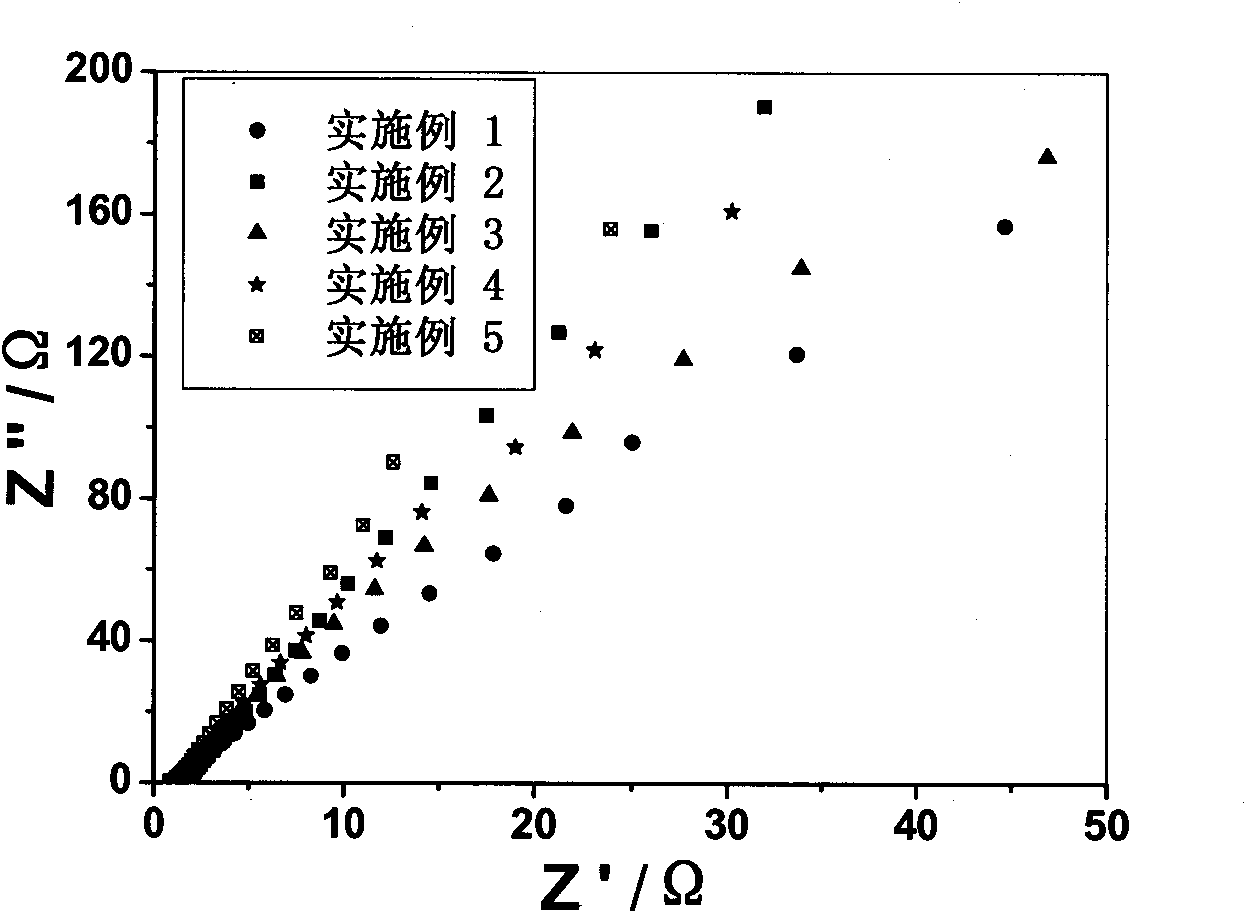

Embodiment 1

[0028] The polymer is synthesized by emulsion polymerization, wherein the mass ratio of the monomer methyl methacrylate, the monomer vinyl acetate, and the oligomer polyethylene glycol diacrylate is 9:1:2; at 25°C, the micron Grade inorganic particles of aluminum oxide are dissolved in acetone solvent, and the above polymer is added, wherein the mass ratio of aluminum oxide to polymer is 1:10; after complete dissolution, the porous substrate with higher mechanical strength- A layer of polypropylene microporous membrane is soaked in the solution containing the polymer coating, that is, a polymer isolation membrane doped with micron-sized inorganic particles aluminum oxide of a certain thickness is prepared.

Embodiment 2

[0030] The polymer is synthesized by emulsion polymerization, wherein the mass ratio of the monomer methyl methacrylate, the monomer vinyl acetate, and the oligomer polyethylene glycol diacrylate is 9:1:1; at 35°C, the nano After dissolving aluminum oxide of high-grade inorganic particles in acetone solvent, add the above polymer, wherein the mass ratio of aluminum oxide to polymer is 1:2; after complete dissolution, double-sided the solution containing polymer coating It is printed on the porous substrate with high mechanical strength-multilayer composite polyethylene and polypropylene microporous membrane, that is, a polymer isolation membrane doped with micron-sized inorganic particles aluminum oxide of a certain thickness is prepared.

Embodiment 3

[0032] The polymer is synthesized by emulsion polymerization, wherein the mass ratio of the monomer methyl methacrylate, the monomer vinyl acetate, and the oligomer polyethylene glycol dimethacrylate is 9:1:1; at 28°C, After dissolving nanoscale inorganic particle titanium dioxide in acetone solvent, add the above polymer, wherein the mass ratio of titanium dioxide to polymer is 1:1; after completely dissolving, spray the solution containing the polymer coating on both sides of the mechanical strength On the higher porous substrate-single-layer polyethylene microporous membrane, a polymer isolation membrane doped with nano-scale inorganic particles is prepared with a certain thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com