Hollow fiber nanofiltration membrane and preparation method thereof

A nanofiltration membrane and fiber technology, applied in the field of membrane separation, can solve the problems of unfavorable large-scale industrial production, high material cost, complex production process, etc., and achieve the effects of shortening production time, simple process and economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment ( 1

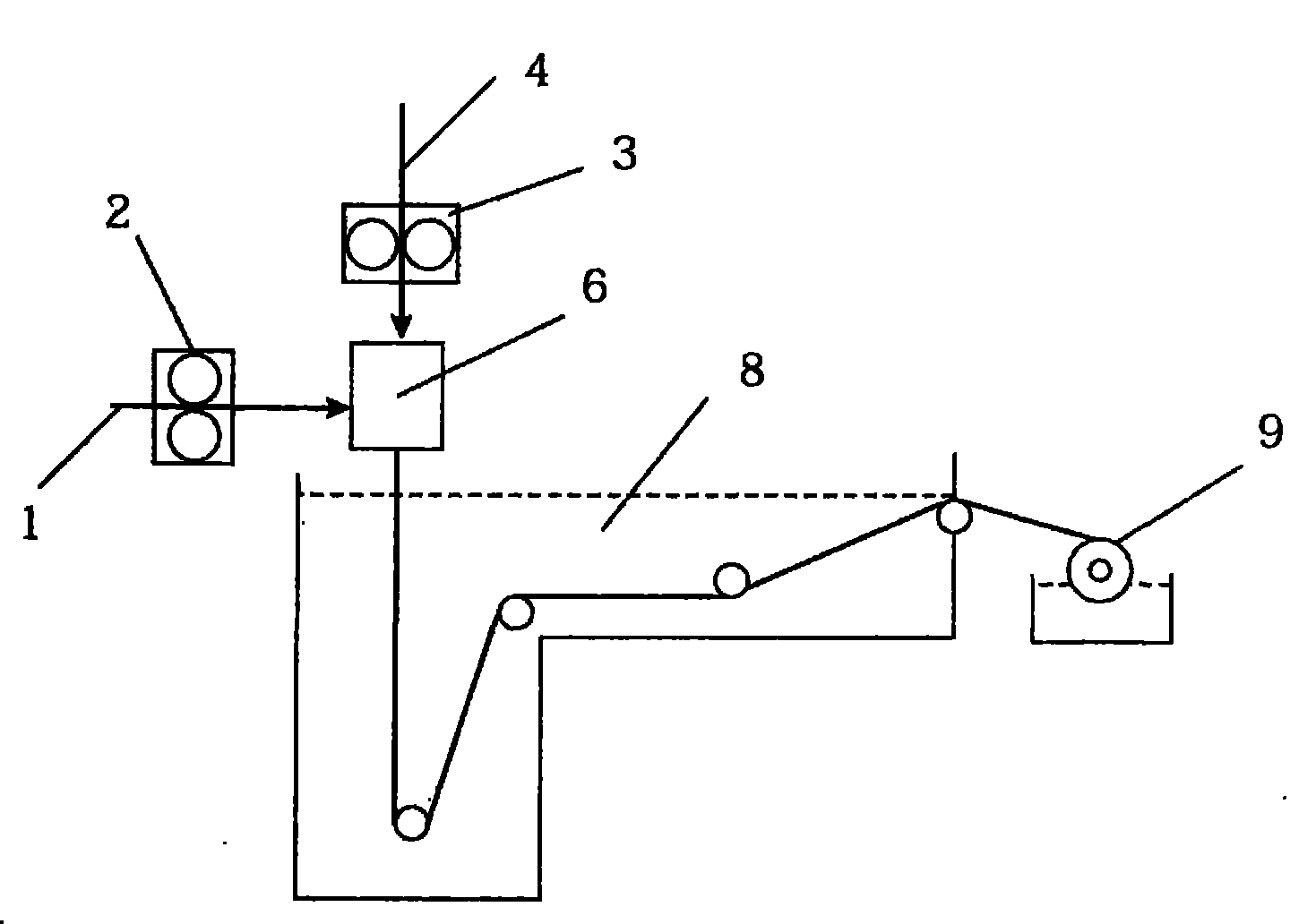

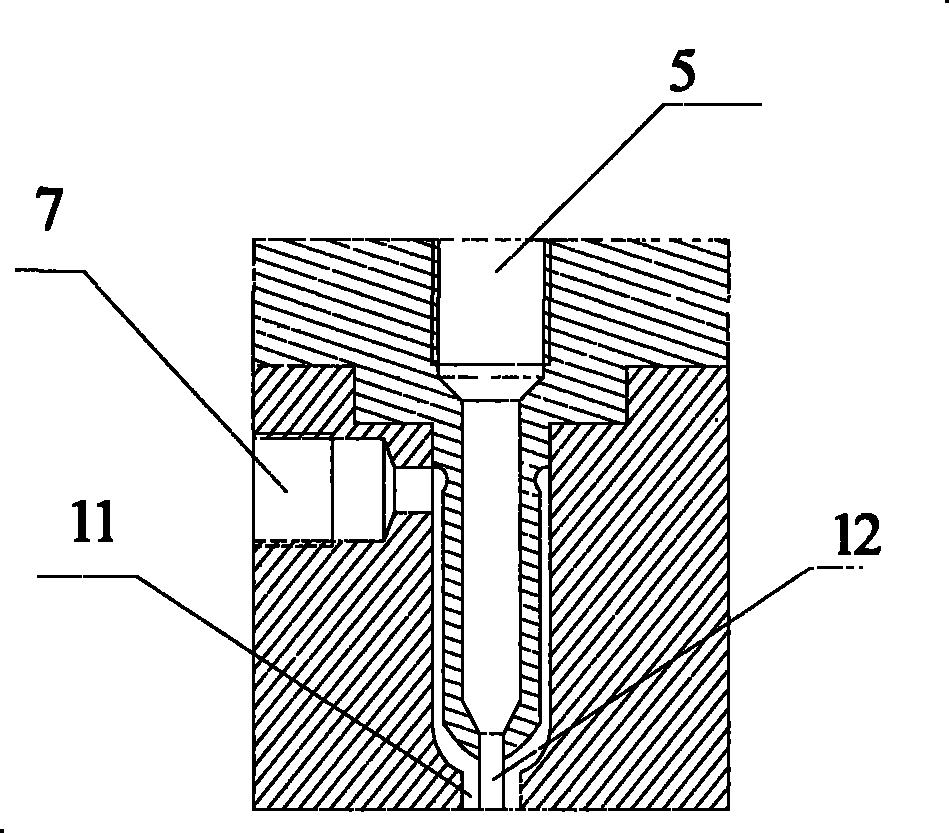

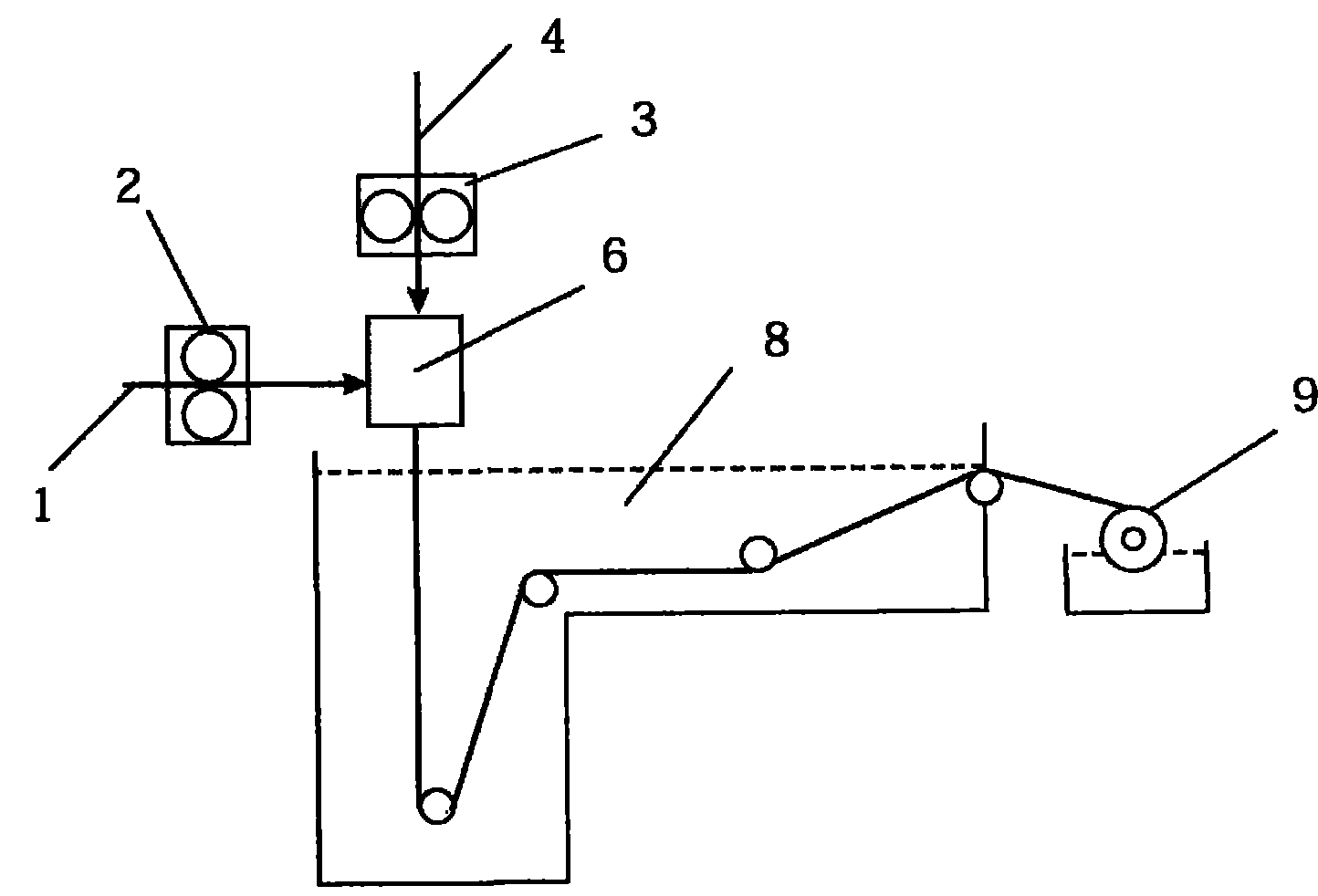

[0028] The device used in the preparation method of a hollow fiber nanofiltration membrane of the present invention is as figure 1 As shown, it includes casting liquid channel 1, core liquid channel 4, gear pump 2, gear pump 3, spinneret 6, coagulation bath 8, and wire winding wheel 9. figure 1 The structural representation of the middle spinneret 6 is shown in figure 2 , including a casting solution channel 7, a core solution channel 5, a core solution port 12, and a casting solution port 11.

[0029] Casting liquid channel 1 is connected with gear pump 2 and connected with casting liquid channel 7 in spinneret 6, core liquid channel 4 is connected with gear pump 3 and connected with core liquid channel 5 in spinneret 6; 7 is connected to each other, and the core liquid channel 5 is connected to the core liquid port 12; it is located on the same axisymmetric center as the casting liquid port 11, and the diameter of the core liquid port 12 is smaller than the diameter of the...

specific Embodiment ( 2

[0040] The device that the present invention adopts is the same as embodiment (one), and the preparation steps of the hollow fiber nanofiltration membrane of the present embodiment are:

[0041] a) Configuration of casting solution:

[0042] The polyacrylonitrile (PAN) high polymer with a molecular weight of 30,000 to 50,000, N,N-dimethylformamide (DMF) and the pore size regulator polyvinylpyrrolidone (PVP) are mixed according to the mass percentage of 18:65:17wt% production;

[0043] b) Preparation of polyacrylonitrile (PAN) ultrafiltration base membrane:

[0044] Water is injected into the core liquid channel 5 of the spinneret 6 from the core liquid channel 4 through the gear pump 3, and the film casting liquid prepared by step a) is injected into the film casting of the spinneret 6 from the film casting liquid channel 1 through the gear pump 2 Liquid channel 7; Then, simultaneously through the core liquid mouth 12 of diameter 0.7mm and the casting film mouth 11 of diamet...

specific Embodiment ( 3

[0048] The device that the present invention adopts is the same as embodiment (one), and the preparation steps of the hollow fiber nanofiltration membrane of the present embodiment are:

[0049] a) Configuration of casting solution:

[0050] Solvent A prepared by mixing polyacrylonitrile (PAN) polymer with a molecular weight of 30,000 to 50,000, dimethyl sulfoxide (DMSO) and tetrahydrofuran (THF) at a volume ratio of 1:1 and pore size regulator diethylene glycol (DG) mixed according to mass percentage 26:72:2wt%;

[0051] b) Preparation of polyacrylonitrile (PAN) ultrafiltration base membrane:

[0052] Water is injected into the core liquid channel 5 of the spinneret 6 from the core liquid channel 4 through the gear pump 3, and the film casting liquid prepared by step a) is injected into the film casting of the spinneret 6 from the film casting liquid channel 1 through the gear pump 2 Liquid channel 7; Then, simultaneously through the core liquid mouth 12 of diameter 1.6mm a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com