Method for preparing noble metal self-organized colloidal crystal

A technology of colloidal crystals and precious metals, applied in the field of preparation of colloidal crystals, can solve problems such as difficult to obtain three-dimensional superlattice and solvent evaporation method, difficult to control, etc., and achieve the effects of easy control, cost reduction, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

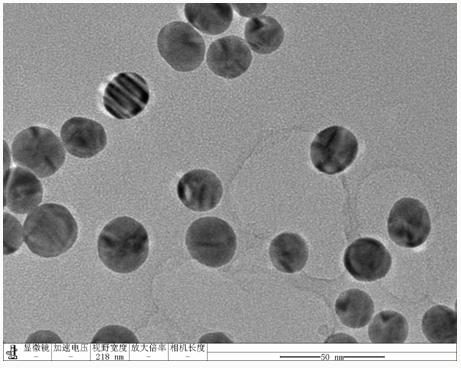

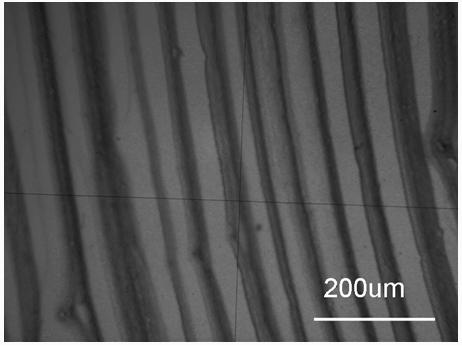

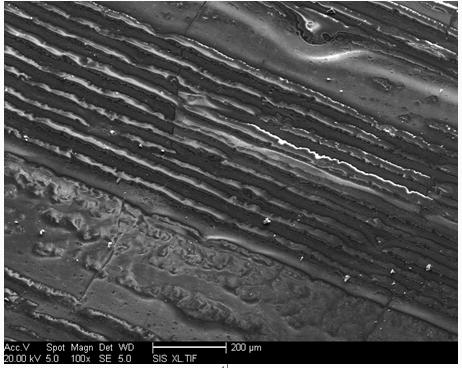

[0009] Specific Embodiment 1: The preparation method of noble metal self-assembled colloidal crystals in this embodiment is carried out according to the following steps: 1. Prepare HAuCl with a concentration of 0.4% to 0.6% (mass) 4 aqueous solution and put it in the refrigerator to cool to 3 ℃ ~ 5 ℃, and prepare AgNO with a concentration of 0.05% ~ 0.2% (mass) 3 Aqueous solution, a sodium citrate aqueous solution with a concentration of 0.05% to 0.2% (mass); 2. Measure the HAuCl prepared in step 1 4 Aqueous solution, AgNO 3 aqueous solution, sodium citrate aqueous solution and water, in which HAuCl 4 Aqueous solution and AgNO 3 The volume ratio of the aqueous solution is 100:4~5, HAuCl 4 The volume-to-number ratio of aqueous solution to sodium citrate aqueous solution is 100:180-220, HAuCl 4 The volume ratio of aqueous solution to water is 1:45~50; 3. First, add water accounting for 95% (volume) of the water weighed in step 2 into the reactor with reflux device, heat to b...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solvent described in Step 5 is water, methanol or ethanol. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the substrate described in step 6 is a glass substrate or a silicon wafer. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com