Infrared phase-changing material and preparation method thereof

A phase-change material and infrared technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem that it is difficult to meet the needs of low-emissivity camouflage, and achieve the effect of reducing links and coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

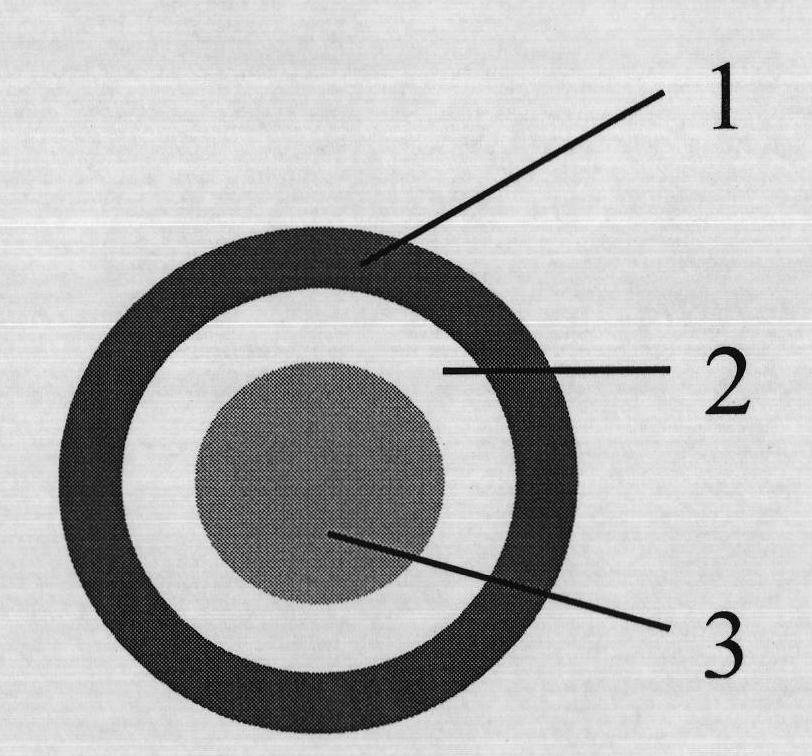

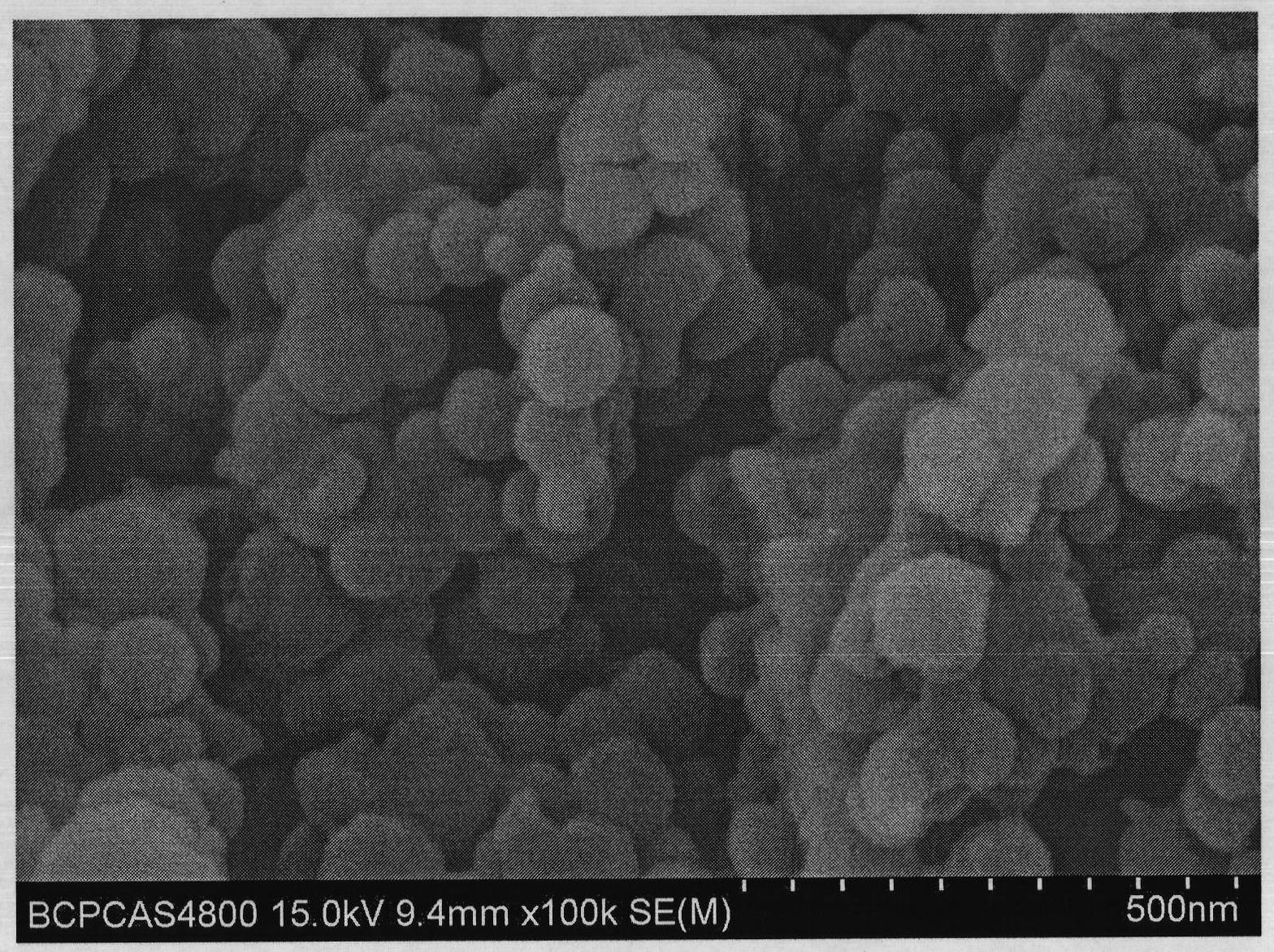

Method used

Image

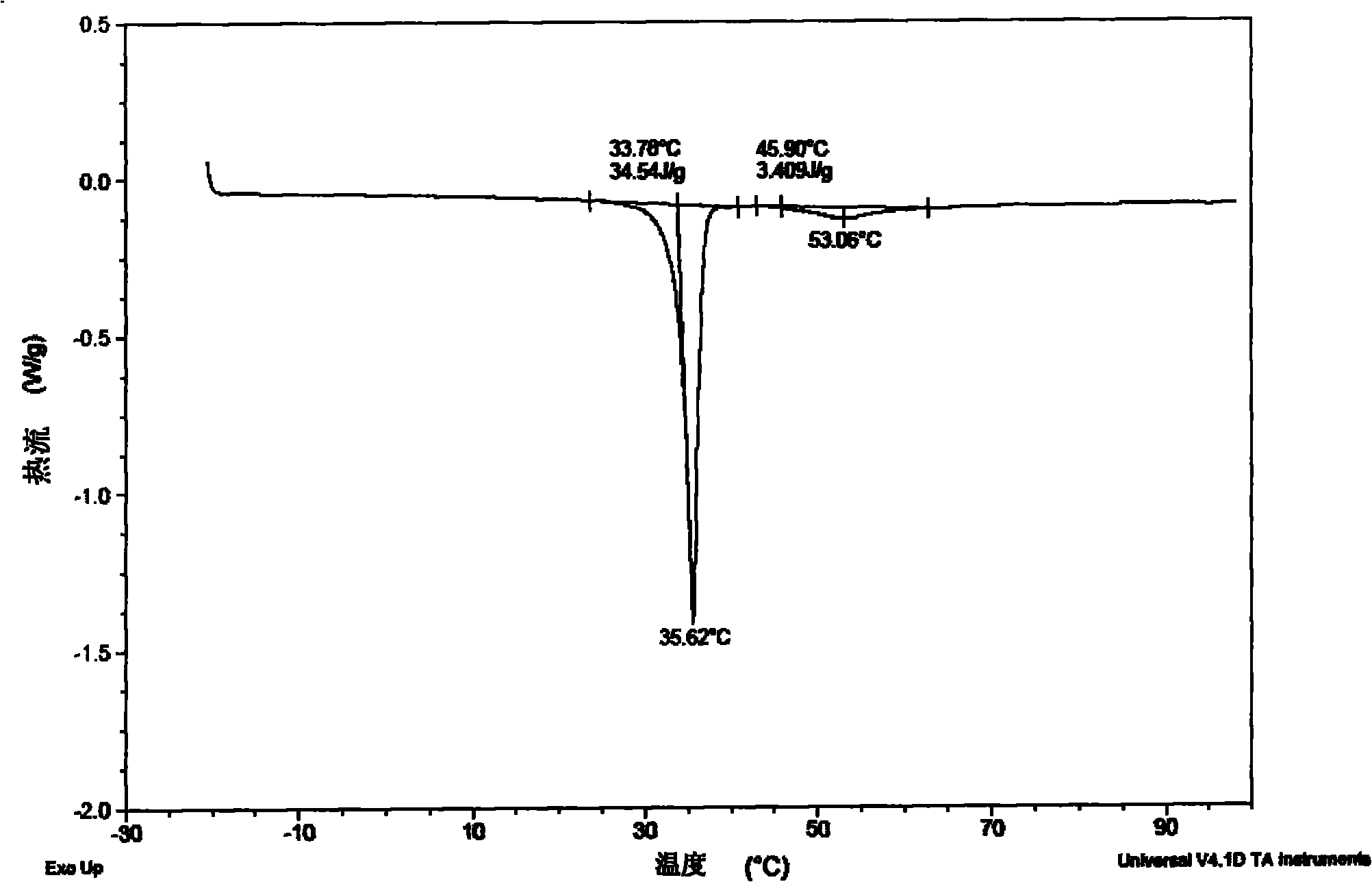

Examples

Embodiment approach 1

[0028] Step 1, using decane as paraffin, weighing 10g of paraffin, 10g of styrene, 1g of methacrylic acid, 0.08g of dodecyl mercaptan, 0.8g of sodium lauryl sulfate, and 0.1g of azobisisobutyronitrile;

[0029] In step 2, the paraffin, styrene, methacrylic acid, dodecanethiol and azobisisobutyronitrile weighed in step 1 are uniformly mixed at room temperature by magnetic stirring;

[0030] Step 3, adding the weighed sodium lauryl sulfate into 120 g of deionized water, and fully stirring at room temperature until the sodium lauryl sulfate is completely dissolved;

[0031] Step 4, the mixed solution obtained in step 2 is added to the mixed solution obtained in step 3, and fully stirred at room temperature for 0.5 hours;

[0032] Step five, ultrasonic emulsifying the mixed solution obtained in step four under ice bath for 10 minutes;

[0033] Step 6, the mixed solution obtained after step 5 ultrasonication is transferred into a four-neck flask with mechanical stirring, condenser...

Embodiment approach 2

[0043] Step 1, using octadecane as paraffin, weigh 10g of paraffin, 10g of styrene, 0.2g of methacrylic acid, 0.08g of dodecyl mercaptan, 0.2g of sodium lauryl sulfate, 0.2g of Triton X-100, and Azodiisobutyronitrile 0.1g;

[0044] Step 2, uniformly mixing the paraffin, styrene, methacrylic acid, dodecanethiol and azobisisobutyronitrile weighed in step 1 at 35° C. with magnetic stirring;

[0045] Step 3, adding the weighed sodium lauryl sulfate and Triton X-100 into 120 g of deionized water, and fully stirring at 35° C. until the two substances are completely dissolved;

[0046] Step 4, the mixed solution obtained in step 2 is added to the mixed solution obtained in step 3, and fully stirred at 35° C. for 0.5 hours;

[0047] Step five, ultrasonic emulsifying the mixed solution obtained in step four under ice bath for 10 minutes;

[0048] Step 6, the mixed solution obtained after step 5 ultrasonication is transferred into a four-neck flask with mechanical stirring, condenser,...

Embodiment approach 3

[0058] Step 1, paraffin wax adopts eicosane, weigh 10g of paraffin wax, 10g of styrene, 0.5g of methacrylic acid, 0.2g of dodecyl mercaptan, 0.1g of sodium lauryl sulfate, 0.2g of triton X-100, and Azodiisobutyronitrile 0.2g;

[0059] Step 2, uniformly mixing the paraffin, styrene, methacrylic acid, dodecanethiol and azobisisobutyronitrile weighed in step 1 at 45° C. by magnetic stirring;

[0060] Step 3, adding the weighed sodium lauryl sulfate and Triton X-100 into 120 g of deionized water, and fully stirring at 45° C. until the two substances are completely dissolved;

[0061] Step 4, the mixed solution obtained in step 2 is added to the mixed solution obtained in step 3, and fully stirred at 45° C. for 0.5 hours;

[0062] Step five, ultrasonic emulsifying the mixed solution obtained in step four under ice bath for 10 minutes;

[0063] Step 6, the mixed solution obtained after step 5 ultrasonication is transferred into a four-neck flask with mechanical stirring, condenser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com