CO2 sustained release foam mask and preparation method thereof

A slow-release, instant noodle technology, which is applied in pharmaceutical formulations, cosmetic preparations, and dressing preparations, etc., can solve the problems of short foaming duration and unsatisfactory cosmetic effect, and achieve long foaming duration and beauty Good effect, the effect of improving the beauty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

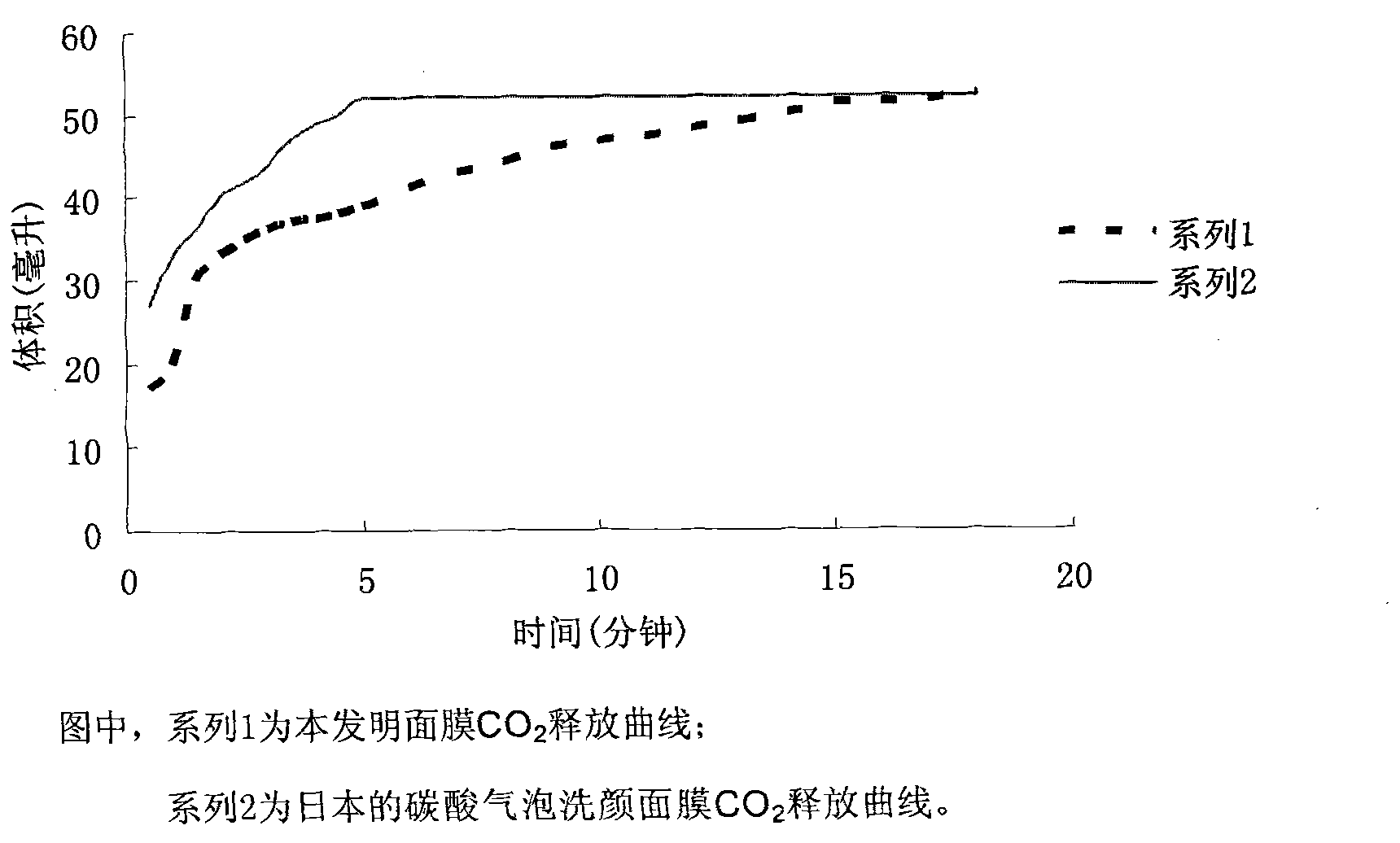

Image

Examples

Embodiment 1

[0085] Embodiment 1 prepares a kind of foam facial mask

[0086] 1. Preparation of solid particles

[0087] Take 0.7g stearic acid and 0.7g poloxamer 188, mix them evenly, add 0.4g alginate, mix evenly, and get mixed powder; mix 0.4g citric acid with appropriate amount of ethanol to make a paste, add the above mixed powder and mix Evenly, make soft materials, pass through a 40-hole sieve, and evaporate ethanol to obtain solid particles, which are packed for later use;

[0088] 2. Preparation of Aqueous Matrix

[0089] Add 0.75g of sodium bicarbonate, 3g of propylene glycol, 8g of polyvinyl alcohol, 2.5g of sodium carboxymethylcellulose and 2g of sorbitol to 30g of water, stir evenly to obtain a water phase; mix 0.25g of polyoxyethylene oleyl ether and 1g Add olive oil to 3.5g of ethanol, heat to 40°C until completely dissolved to obtain the alcohol phase; add the alcohol phase to the water phase, heat to dissolve at 70-80°C, stir evenly, add 0.2g of spices, 0.2 2 g of ethan...

Embodiment 2

[0091] Embodiment 2 prepares a kind of foam facial mask

[0092] 1. Preparation of solid particles

[0093] Weigh 0.5g of glyceryl behenate and 0.2g of poloxamer 237, and mix well; add 0.3g of algal earth, and mix well. Add 0.1g of citric acid to the above mixed powder, mix evenly, heat and melt, sieve and granulate, cool and granulate to obtain solid granules, pack for later use;

[0094] 2. Preparation of Aqueous Matrix

[0095] Add 0.3g sodium bicarbonate, 2g propylene glycol, 8g polyvinyl alcohol, 2.5g sodium carboxymethylcellulose and 3g glycerin to 30g water and stir well. Add 0.25g polyoxyethylene oleyl ether and 1g jojoba oil to 3.5g ethanol, heat to 40°C until completely dissolved. Add the alcohol phase to the water phase, heat to dissolve (70-80°C) and stir evenly, add 0.2g of fragrance, 0.2g of ethylparaben and 0.2g of propylparaben in ethanol solution at 45°C, and dissolve Evenly, the aqueous phase matrix is obtained, and the package is ready for use.

Embodiment 3

[0096] Embodiment 3 prepares a kind of foam facial mask

[0097] 1. Preparation of solid particles

[0098] Weigh 0.2g glycerol palmitostearate, 0.04g poloxamer 188, mix well, and dissolve with ethanol; mix 0.25g alginate and 0.4g tartaric acid, put them into a coating pan, spray the ethanol solution Put it into a rotating coating pan for granulation to obtain solid granules, which are packed for later use;

[0099] 2. Preparation of Aqueous Matrix

[0100] Add 0.65g of sodium bicarbonate, 2g of polyethylene glycol, 7g of polyvinyl alcohol, 2.5g of pectin and 1g of water-soluble lanolin to 30g of water, and stir evenly. Add 0.25g polyoxyethylene oleyl ether and 0.5g castor oil to 3.5g ethanol, heat to 40°C until completely dissolved. Add the alcohol phase to the water phase, heat to dissolve (70-80°C) and stir evenly. At 45°C, add 2g of ethanol solution in which 0.2g of perfume and 0.4g of ethylparaben are dissolved, and dissolve evenly to obtain the water phase matrix. Pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com