Method for continuously preparing hexanolactam by using cyclohexanone-oxime Beckmann rearrangement reaction

A rearrangement reaction, cyclohexanone oxime technology, applied in the preparation of lactam, chemical instruments and methods, organic chemistry, etc., can solve the problems of complicated device design and operation control, uneasy stability of reaction results, and a large amount of inert solvents , to achieve the effect of easy device design, stable operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

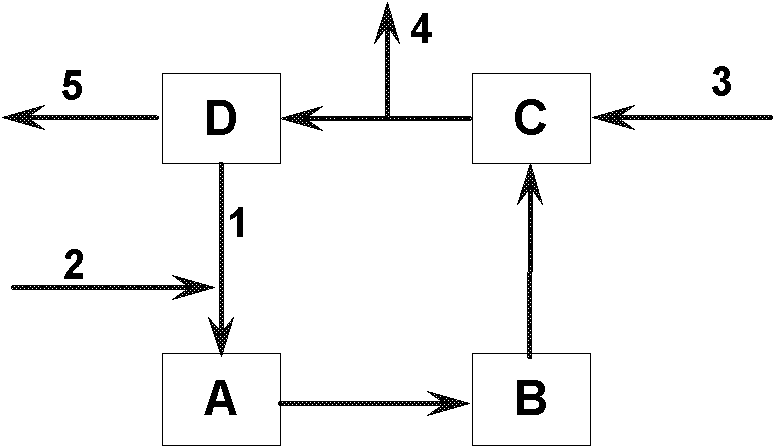

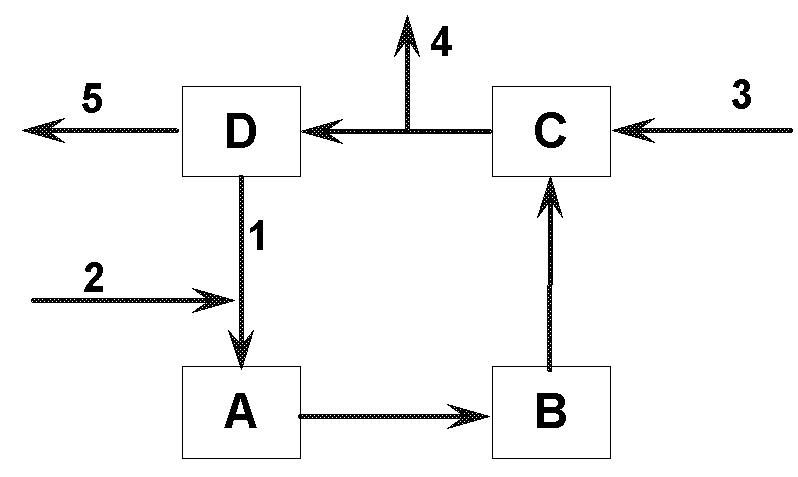

[0026] The present invention can be achieved through a figure 1 The shown circulation reaction system consisting of circulation pump A, cooler B, mixing reactor C and aging reactor D is implemented.

[0027]The rearrangement reaction solution 1 with a mass content of caprolactam of 50.2% and a flow rate of 20.2 kg / h from the aging reactor D is mixed with oleum with a flow rate of 0.68 kg / h and a mass content of sulfur trioxide of 21%. Finally, it is sent to the temperature controller through the circulation pump A, and the temperature is controlled at 80°C, and then mixed with the cyclohexanone oxime-cyclohexane solution with a flow rate of 1.70kg / h and a cyclohexanone oxime mass content of 39.8%. Reactor C mixes and reacts and enters aging reactor D under normal pressure, where cyclohexane 4 flows out from the gas phase pipeline and is condensed and recovered. After the liquid phase is aged at 100°C for 30 minutes, a part of The rate flows out of the reaction system as the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com