Preparation of high-temperature acidification corrosion inhibitor

An acidification corrosion inhibitor and high temperature technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of using at high temperatures that do not reach 150°C-180°C

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 60 parts of sulfathiazole solution, 15 parts of phenolic resin, 10 parts of dodecyl dimethyl benzyl ammonium chloride, 7 parts of amino polysiloxane, 15 parts of diethylene glycol compound in parts by weight, and add to Dosing in the reactor and stirring for 35 minutes to obtain the product;

[0018] The preparation of the sulfathiazole solution: take 45 parts of 2-aminothiazole and 50 parts of p-nitrobenzenesulfonyl chloride in parts by weight, put them into the reaction kettle and stir, keep the temperature at 40°C, and add 50 parts of sodium bicarbonate after 2.5 hours , Continue to react for 4.5 hours to obtain the solution.

Embodiment 2

[0020] Take 50 parts of sulfathiazole solution, 10 parts of phenolic resin, 14 parts of dodecyl dimethyl benzyl ammonium chloride, 5 parts of aminopolysiloxane, and 20 parts of diethylene glycol in parts by weight. Dosing in the reaction kettle, stirring for 30 minutes to obtain the product;

[0021] The preparation of the sulfathiazole solution: take 50 parts of 2-aminothiazole and 47 parts of p-nitrobenzenesulfonyl chloride in parts by weight, put them into the reactor and stir, keep the temperature at 40°C, and add 45 parts of sodium bicarbonate after 2 hours , Continue to react for 5 hours to obtain the solution.

Embodiment 3

[0023] Take 56 parts of sulfathiazole solution, 12 parts of phenolic resin, 15 parts of dodecyl dimethyl benzyl ammonium chloride, 10 parts of amino polysiloxane, 10 parts of diethylene glycol compound in parts by weight, and add to Dosing in the reaction kettle and stirring for 40 minutes to obtain the product;

[0024] Among them, the preparation of sulfathiazole solution: take 48 parts of 2-aminothiazole and 45 parts of p-nitrobenzenesulfonyl chloride in parts by weight, put them into the reaction kettle and stir, keep the temperature at 40°C, and after 3 hours, add 48 parts of sodium bicarbonate , Continue to react for 4 hours to obtain the solution.

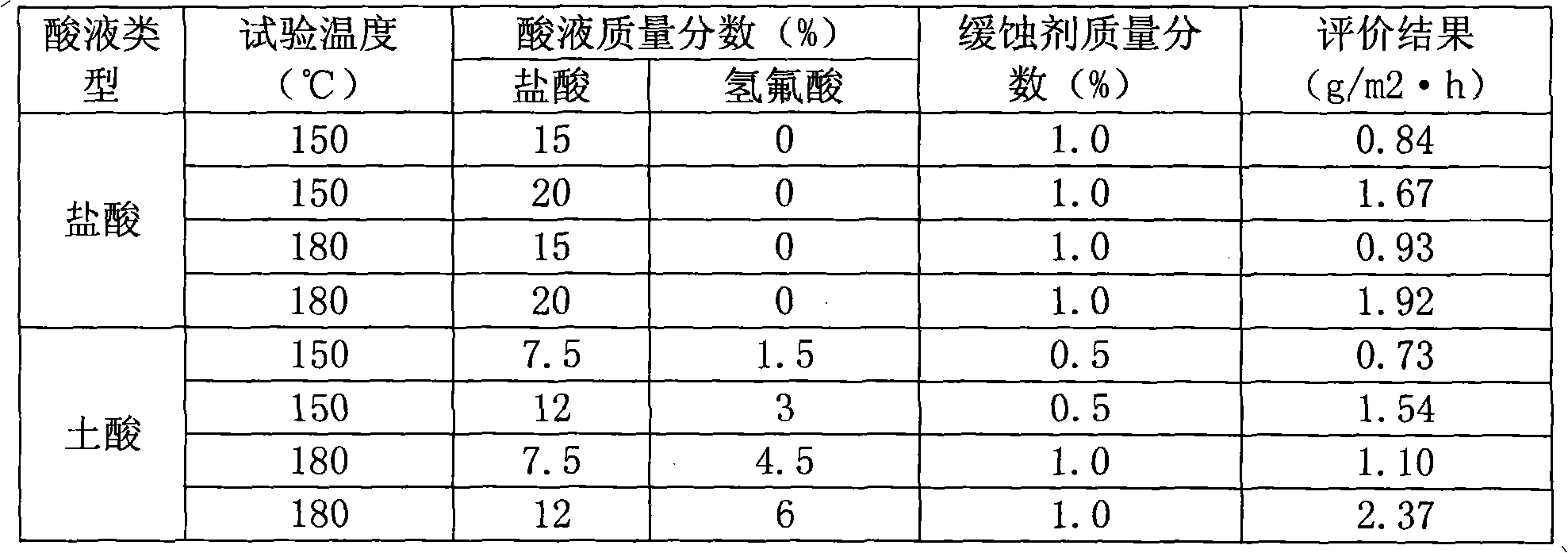

[0025] Verification test:

[0026] In a production well in Xinjiang, the initial oil production was 29 tons per day, but it dropped to 13 tons per day after 2 months. The first measure: mechanical descaling. After the measure, the daily oil output was 23 tons, but the scale was regenerated in a short period of time. So th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com