Laser light source device of high-power semiconductor

A laser light source, semiconductor technology, applied in semiconductor laser devices, laser devices, devices for controlling laser output parameters, etc., can solve the problems of short life, large volume, low energy efficiency, etc. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

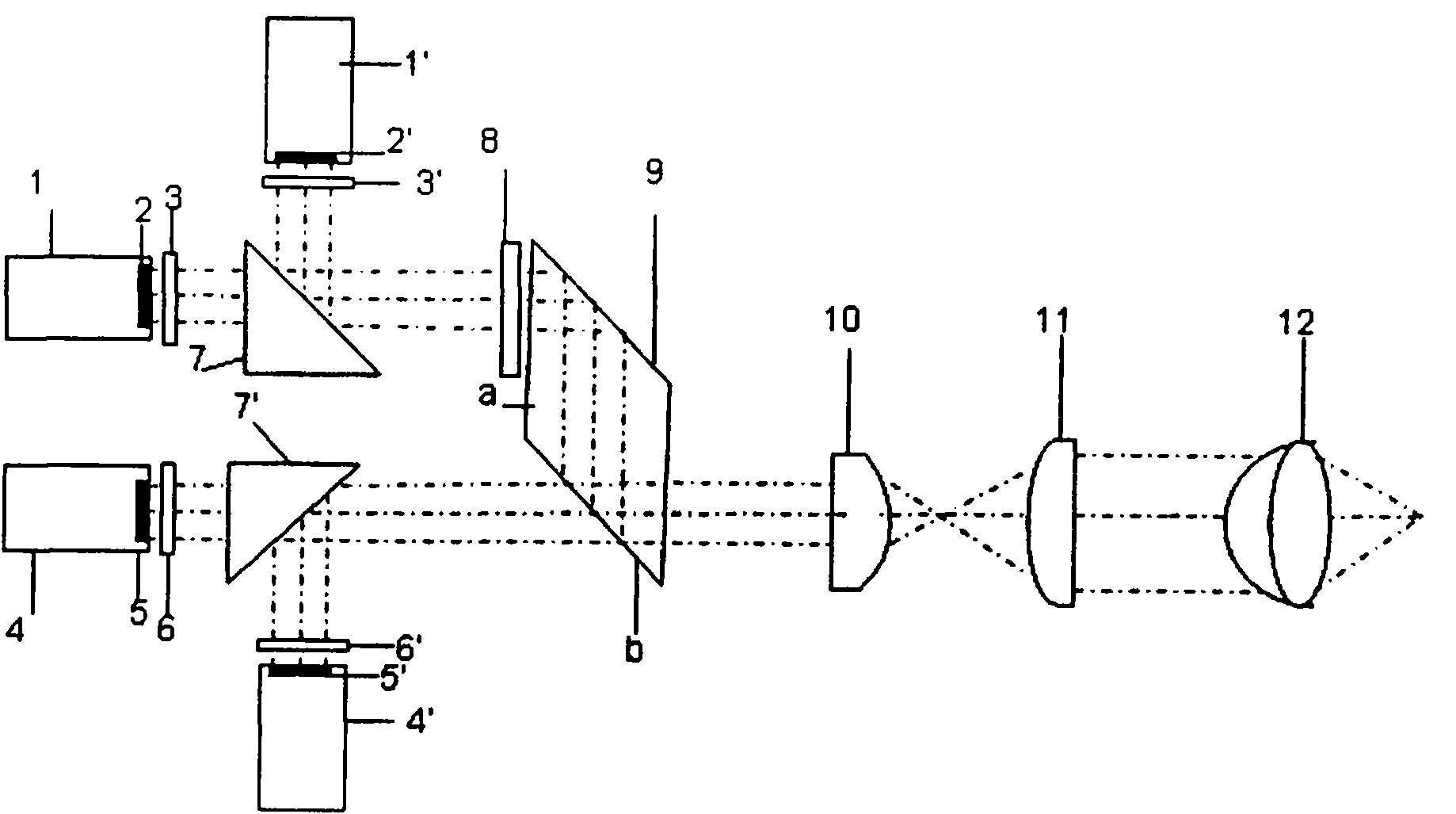

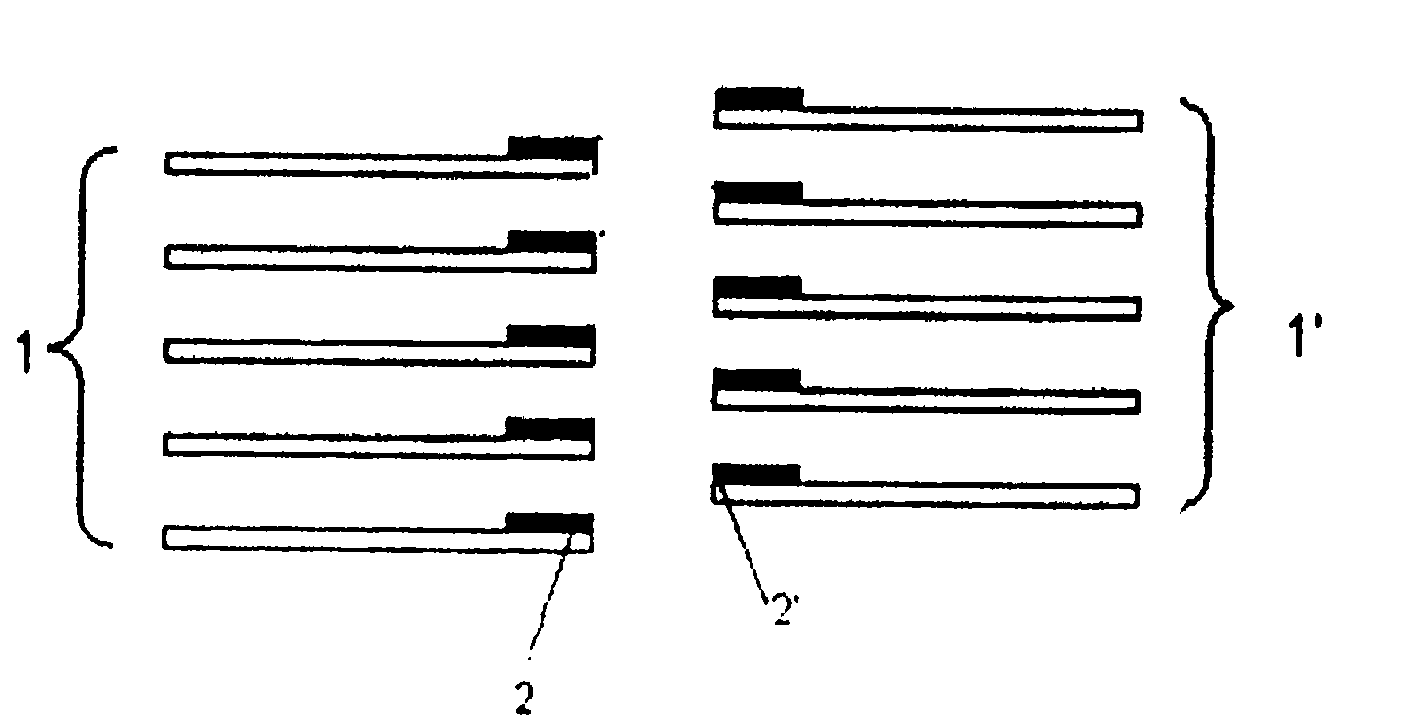

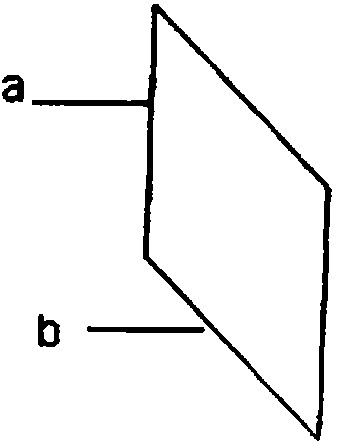

[0037] like figure 1Shown, the high-power semiconductor laser light source device that the present invention provides is by first semiconductor laser stack 1, the second semiconductor laser stack 1 ', the 3rd semiconductor laser stack 4, the 4th semiconductor laser stack 4 '; Fast axis collimating lens 2, second fast axis collimating lens 2', third fast axis collimating lens 5, fourth fast axis collimating lens 5'; first slow axis collimating lens 3, second slow axis collimating lens Straight lens 3', the third slow axis collimating lens 6, the fourth slow axis collimating lens 6'; the first isosceles right triangle reflective prism 7, the second isosceles right triangle reflective prism 7'; half wave plate 8; A rhombic polarizing coupling prism 9; a beam expander system composed of a first cylindrical lens 10 and a second cylindrical lens 11 and a focusing system 12 composed of a doublet lens;

[0038] The first fast-axis collimating lens 2, the second fast-axis collimating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com