Preparation method of modified silicon gel absorbing agent used for protecting on-vehicle fuel batteries

A fuel cell and silica gel adsorption technology, which is applied in fuel cell additives, solid electrolyte fuel cells, battery/battery traction, etc., can solve the problems of unsuitable vehicle-mounted fuel cell work requirements and rare development of trace sulfur dioxide, and achieve Good ability to adsorb trace amounts of sulfur dioxide, easy to operate, and large saturated adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) According to the ratio of 2.15: 3.8: 1: 0.033 by mass ratio, tetraethoxysilane, absolute ethanol, deionized water and HCl solution with a concentration of 0.05mol / l were added in the round bottom flask successively, stirred, React for 1 day to obtain a transparent and clear sol precursor;

[0017] (2) Take a certain amount of the sol precursor prepared in step (1), without diluting with absolute ethanol, quickly drop in 3-aminopropyltriethoxysilane whose mass is 11% of the sol precursor mass, and stir for 5 seconds A transparent solid gel was obtained. After the solid gel was aged for 0.5 h, it was crushed, placed in an oven and dried at 80°C for 1 day, and the dried silica gel particles were uniformly ground to obtain the amino-modified silica gel adsorbent.

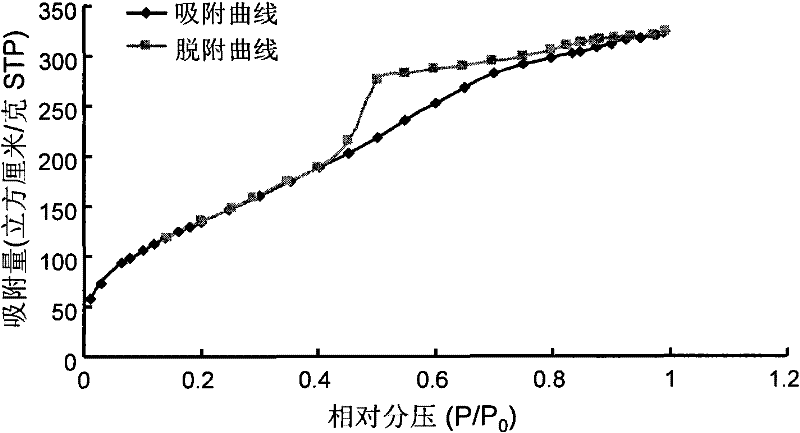

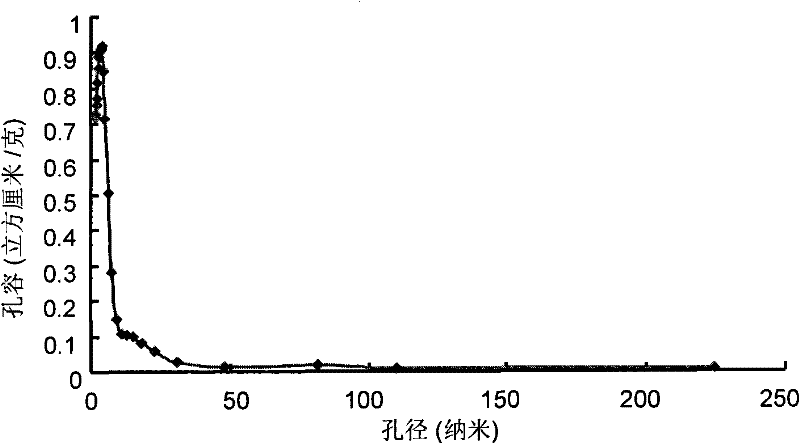

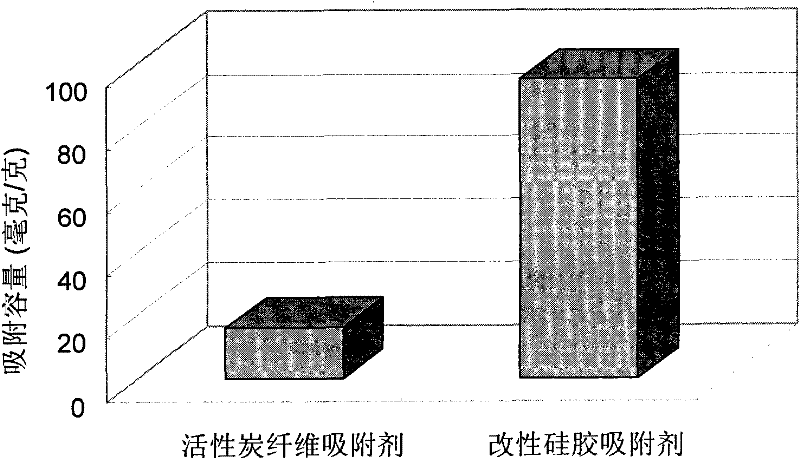

[0018] The obtained dried gel has low strength and can be easily ground into a powder adsorbent, and the product has a good ability to adsorb trace amounts of sulfur dioxide. The specific surface area of ...

Embodiment 2

[0021] (1) According to the ratio of 2.15: 3.8: 1: 0.033 by mass ratio, tetraethoxysilane, absolute ethanol, deionized water and HCl solution with a concentration of 0.05mol / l were added in the round bottom flask successively, stirred, After 14 days of reaction, a transparent and clear sol precursor was obtained;

[0022] (2) Take a certain amount of the sol precursor obtained in step (1), add the dehydrated ethanol whose quality is 3 times of the sol quality to dilute, and quickly drop in the 3-aminopropyl triethoxy that the quality is 33% of the sol precursor quality base silane, and stirred for 1 min to obtain a transparent solid gel. After the solid gel was aged for 3 hours, it was crushed, placed in an oven and dried at 50°C for 3 days, and the dried silica gel particles were uniformly ground to obtain the amino-modified silica gel adsorbent.

[0023] The obtained dry gel strength is similar to that of the product in Example 1.

Embodiment 3

[0025] (1) According to the ratio of 2.15: 3.8: 1: 0.033 by mass ratio, tetraethoxysilane, absolute ethanol, deionized water and HCl solution with a concentration of 0.05mol / l were added in the round bottom flask successively, stirred, React for 1 day to obtain a transparent and clear sol precursor;

[0026] (2) Take a certain amount of the sol precursor obtained in step (1), add the dehydrated ethanol whose quality is 3 times of the sol quality to dilute, and quickly drop in the 3-aminopropyl triethoxy that the quality is 11% of the sol precursor quality base silane, a transparent solid gel can be obtained under stirring. After the solid gel was aged for 0.5 h, it was crushed, placed in an oven and dried at 80°C for 3 days, and the dried silica gel particles were uniformly ground to obtain the amino-modified silica gel adsorbent.

[0027] The obtained silica gel adsorbent is similar to that of Example 1. It has a good ability to adsorb trace amounts of sulfur dioxide, has a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com